A holistic approach to managing mycotoxins in poultry

How to recognise and mitigate emerging and masked mycotoxins, and their synergistic effects.

Scientific research has discovered significant insights about the harmful effects that individual mycotoxins pose to poultry feed, bird health and food safety. However, much less focus has been placed on the problems that occur from the interaction of different mycotoxins or the synergies that arise from combinations of these contaminants.

Addressing this risk is critical as mycotoxins become more prevalent in ingredients, silage and finished feed. It is estimated that mycotoxins are present in more than 80% of agricultural commodities, compared to a contamination rate of 25% in 1985. Increased globalisation and a pattern of more extreme weather events are some of the factors accounting for this increase in mycotoxin contamination. Managing mycotoxin risk cannot be pushed downstream to the feed mill as most mycotoxins are highly stable and capable of withstanding the intense thermal processes occurring during feed extrusion and processing.

Simply defined, mycotoxins are secondary metabolites produced by various moulds and can develop in crops, raw materials, silages and finished feeds. Mycotoxins can arise in the field, during transport and in storage and are commonly produced in grains such as maize, and wheat, by-products such as DDGS and various protein meals. A general rule of thumb is that mycotoxins developing in byproducts are generally viewed to be present at 3 times the levels found in grains. More than 600 individual mycotoxins have been reported, however, some of the most common mycotoxins affecting poultry and livestock feed are Aflatoxins, Ochratoxins, Fumonisins, Deoxynivalenol (DON), T-2 toxin and Zearalenone.

Emerging mycotoxins

In addition to common mycotoxins, researchers are focusing on a category referred to as ‘Emerging Mycotoxins’. Although these mycotoxins are neither routinely analysed, nor legislatively regulated, evidence shows they are increasing rapidly and can pose significant feed safety concerns based on the synergies resulting from their interactions (Table 1).

Among the list of emerging mycotoxins, moniliformin and fusaric acid certainly need attention as they are quite capable of affecting the health and performance of poultry. Fusaric acid, which is present more often than DON in feeds and raw materials, is capable of increasing DON toxicity in a synergistic manner. Moniliformin, on the other hand, is found as co-contaminant of Fumonisins and has been implicated in affecting poultry performance.

Masked mycotoxins

‘Masked mycotoxins’ relate to toxins that may be present in feed but cannot be analysed using conventional methods due to their conjugation with molecules such as glucose. However, upon reaching an animal’s gastrointestinal tract, they can release mycotoxin from the conjugated form and adversely affect the animal. DON-3-glucoside found in maize, wheat, barley, oats, maize silage and finished feed is a major mycotoxin of concern in the US and Europe as once taken in, it converts to the DON mycotoxin. Other masked mycotoxins that have been studied include Zearalenone-14-glucoside, Nivalenol-3-glucoside etc (Table 2).

Mycotoxin co-occurrence is the rule; not the exception

The nature of mould proliferation points to the propensity for mycotoxins to increase rapidly. A single mould may produce several mycotoxins and one ingredient may be contaminated with several moulds. These 2 factors coupled with the fact that animal feed may contain many raw materials such as maize, DDGS, soybean meal, can lead to the presence of multiple mycotoxins in the complete feed. It is, therefore, fair to say mycotoxin co-occurrence is the rule and not the exception.

While the harmful effects of emerging and masked mycotoxins can build on one another to create an ‘additive’ effect, a special concern is the synergistic issues that arise when the adverse effects of individual mycotoxins are amplified as they interact. Research studies have seen such an exponential effect when Aflatoxin combines with T-2 Toxin or Ochratoxin A. Considering the number of ingredients in a single animal feed, these findings suggest mycotoxin risk can increase quickly depending on the relationships taking across a feed’s ingredient profile.

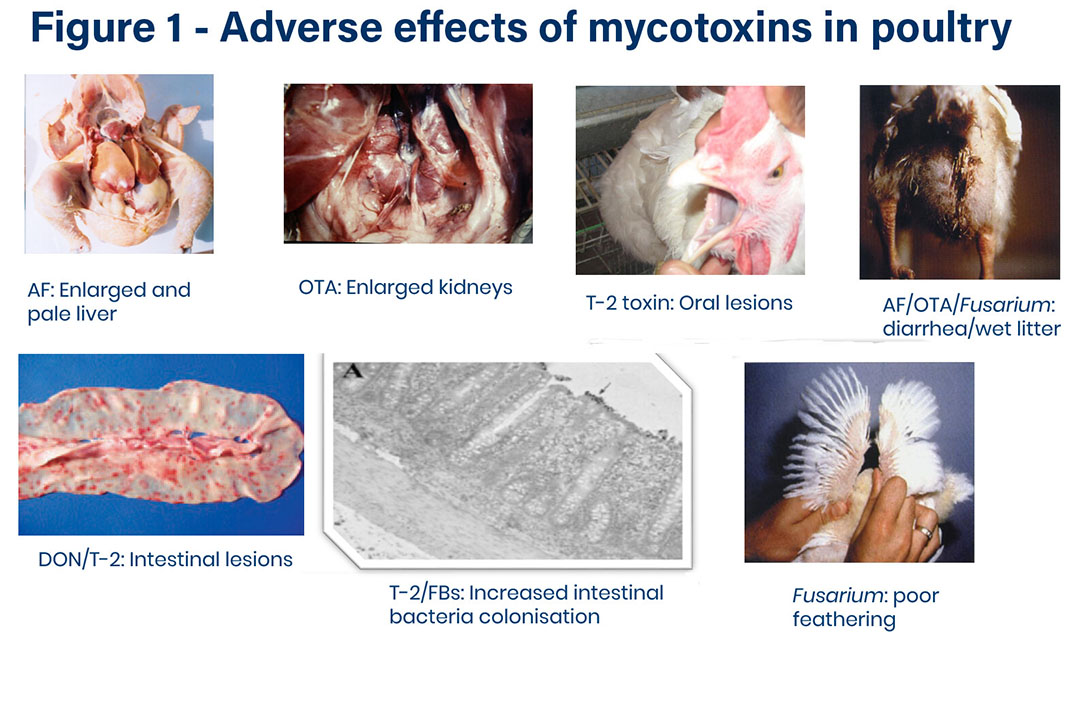

The implications for birds and producers

The harmful consequences of these interactions can show up in a range of health problems in poultry (Figure 1). For example, Aflatoxin is associated with enlarged and pale livers, while OTA exposure may lead to enlarged kidneys and Fusarium mycotoxins such as DON and T-2 can facilitate an increase in bacterial colonisation in the intestines. For breeders, the synergistic effects of Aflatoxins, Ochratoxins, T-2 and DON can compromise utilisation of calcium and phosphorous, resulting in thinner eggshells and potentially fewer hatched chicks per hen housed. Many mycotoxins have been associated with poor immunity either through lowering antibody production or compromising cell-mediated and innate immunities. Compromised immunity can lead to increased morbidity and mortality levels ultimately affecting producer’s bottom line and reputation in the market negatively.

The solution is an integrated approach across the supply chain

Simply stated, mycotoxin detection can be complicated, and some mycotoxins are particularly hard to detect as they may be at levels below regulatory thresholds. Just because an ingredient meets acceptable regulatory levels does not mean it is free of any particular mycotoxin.

A comprehensive approach to assessing mycotoxin risk should include:

- Detection and evaluation: Rapid mycotoxin detection in feed ingredients can provide quick analysis and inform risk management practices. The Trouw Nutrition Mycomaster tests 6 key mycotoxins in a short period of time making it the most useful and rapid tool. Another key advantage of Mycomaster is, unlike many other methods it can analyse mycotoxins in complete feed also.

- Early data to drive decisions: In a global economy, it is important to assess how threats in one part of the world can compromise ingredients and threaten feed produced in other regions. Comparative technologies, such as the NutriOpt Mycotoxin Adviser and NutriOpt Mycotoxin Monitor, can provide an early warning indicator of a potential feed safety concern. More than 700 analyses are conducted each week from locations around the globe.

- Supply chain best practices: Even with the most innovative tools and technologies, effective mitigation of mycotoxins requires an integrated approach that begins even prior to planting. For example, feed crops should be rotated – i.e. farmers should not plant maize year after year, but should rotate the ingredients produced in a field. Harvesting practices should consider weather and climate factors, and extreme weather may require adapting harvest times. Crops must be protected from environmental threats during transportation to storage and again as they are delivered to the feed mill. Adequate hygiene measures at the mill and in storage provide additional safeguards to protect the integrity of ingredients. Interventions such as the application of organic acids and surfactants during processing may provide the added benefit of improving the efficiency of feed production. Data from technologies deployed across the supply chain, such as the NutriOpt Mycotoxin Monitor (see image below), can help guide decisions such as adding a mycotoxin binder into feed, or even reformulating feed based on mycotoxin levels. Upon leaving the production facility, finished feed requires safeguards to protect its final transport to the farm. Farm management practices including feed bin and feed trough hygiene as well as proper ventilation in the sheds can help in managing mycotoxins and protect poultry.

Like all aspects of livestock production, an integrated approach tailored to the unique challenges on the farm can support feed safety and help manage not only well-known mycotoxins but also emerging and masked mycotoxins.