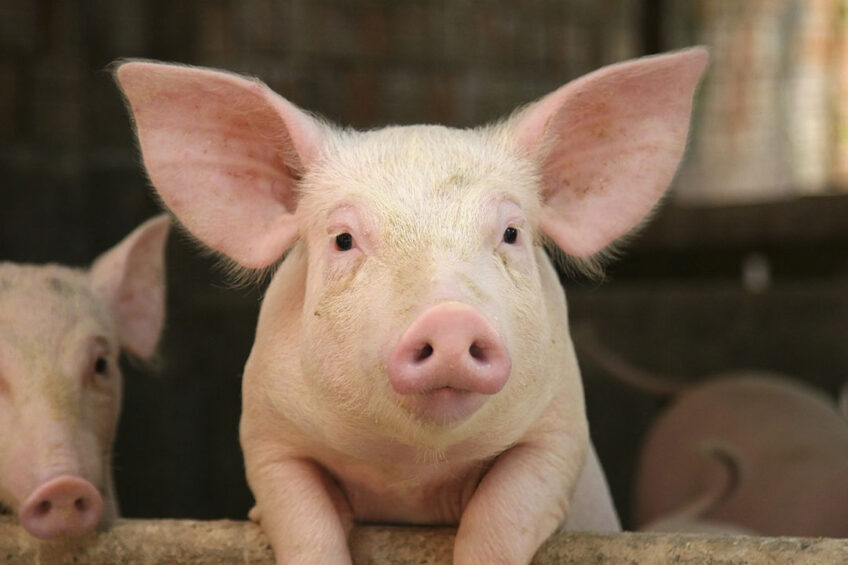

Alleviate effects of zearalenone in gilts

Mycotoxin challenges are an increasing concern in animal production. Around 25-30% of agricultural commodities are contaminated with mycotoxins, accounting for significant economic losses. One of the most prevalent mycotoxins is zearalenone (ZEN). In recent years, around 50% of all feed was contaminated with the mycotoxin ZEN.

The molecular structure of ZEN resembles the structure of estrogen, allowing ZEN to bind to estrogen receptors which can result in reproductive disorders and infertility in farm animals. A characteristic sign of ZEN contamination in gilts is vulva hypertrophy (VH). Symptoms of VH include swelling and redness of the vulva.

The high prevalence highlights the need for the inclusion of mycotoxin binders in animal feed to reduce the potential impact on performance and animal health. However, this statement raises the question of whether all mycotoxin binders have the same effect.

Evaluating the effect of mycotoxin binders

Orffa Additives, in collaboration with a well-known consultant in the Philippines, performed a practical trial to evaluate the effects of 3 different commercial mycotoxin binders on their ability to alleviate the negative effects caused by ZEN. On a commercial farm experiencing ZEN intoxication symptoms such as VH, the 3 binders were compared in 2 different batches of gilts starting in a different age stage (nursery and growing gilts). The first binder was based on yeast, algae, plant extracts, minerals (A). The second binder was based on bentonite, enzymes, biological components, plant and algae extracts, and yeast (B) and the third binder was Excential Toxin Plus, including 2 clay minerals, yeast, organic acids, and betaine (C).

The most important results of the 3 binders on reducing the negative effects of ZEN include:

- Improved performance

- Reduced VH cases

- Estrus before 180 days of age

Improved performance under ZEN contamination

One of the direct economic losses related to mycotoxin contamination is reduced growth performance. This is an important parameter to take into account when determining the effects of the different mycotoxin binders. When comparing the performance results of nursery gilts over a period from 73-180 days of age and growing gilts over a period of 115-180 days of age, for gilts that receive 3 different types of mycotoxin binders, differences in performance are found. Gilts from the third group (C) had higher daily gain and final body weight, and lower FCR compared to the other groups (Figure 1).

Figure 1 – Body weight (BW), average daily gain (ADG) and feed conversion ratio (FCR) of gilts receiving 3 different commercial mycotoxin binders.

Reduce ZEN symptoms

Besides the ability of a binder to improve growth performance during ZEN contamination, it’s also important that a mycotoxin binder reduces symptoms such as VH. When looking at nursery gilts, the number of VH cases was most reduced in group C compared to A and B. In growing gilts, the number of VH cases reduced similarly both in group B and C. Group A showed an increase in VH cases (Figure 2).

Another negative effect resulting from ZEN contamination is the inability to show estrus. The ability to show estrus before 180 days of age in this trial was defined as a selection criterium for replacement gilts. In the group with nursery gilts, 2 were selected as replacement gilts since these were the only gilts that showed their first estrus before 180 days of age. Both gilts were from group C. In the growing gilts, 12 were selected as replacement gilts originating from different groups.

Figure 2 – Percentual reduction of cases of vulva hypertrophy in replacement gilts receiving 3 different mycotoxin binders

Mycotoxin binder with high efficacy

When including mycotoxin binders in a practical situation with existing ZEN contamination, different results are observed depending on the used product. Overall, the inclusion of binder C (Excential Toxin Plus) to the diets of replacement gilts led to better growth performance and reduced signs of vulva hypertrophy. This allows for the conclusion that this product reduces the negative effects of ZEN on reproductive and growth performance compared to other commercially available mycotoxin binders.

The improvement in health, performance, and fertility can be attributed to the good synergistically functioning of the 5 ingredients: aluminosilicates and yeast aimed at the binding of mycotoxins and ingredients that aim to reduce the growth of fungi in stored feed and to support intestinal integrity and liver health.

For more information, contact Jolien van Soest (soest@orffa.com)