Economically optimal amino acid levels in broiler diets

Amino acid recommendations usually allow for maximum technical or biological performance, which is not necessarily the same as best economic performance. Production goals of a broiler operation depend on optimal dietary amino acid levels. Experimental data suggests that many effects of increasing levels of dietary amino acids on economic performance in subsequent phases are additional.

By Dr. Andreas Lemme and Dr. Johann Fickler, Evonik Degussa GmbH, Germany

In order to formulate compound feed properly, nutritionists need to specify the minimum target levels for energy and important nutrients, which also include essential amino acids. However, not only are constraints important, but interactions between nutrients need to be considered in order to realise optimal performance. In this context the nutritionist needs sources of information indicating suitable specifications or optimal dietary amino acid levels. Different sources are usually available, including recommendations given by official authorities and organisations, breeding companies, or amino acid producers.

However, although in some of the recommendations factors are considered, which may affect optimal dietary amino acid levels, the most important criterion has not been considered – the economical side of production and profitability of an operation. Changing economic conditions have an impact on the optimal dietary amino acid of a diet, which can be demonstrated by this model.

Several attempts have been made to combine experimental data with key economic figures. The two most prominent definitions for profitability are probably feed cost/kg weight gain or breast meat, and gross margin, which is income over feed cost per bird or per flock. Meta-analyses of performance data of broilers lysine, methionine+cysteine and threonine experiments found in literature revealed that feed cost/kg weight gain minimised at other amino acid levels compared to those required for maximising weight gain and breast meat yield, or minimising feed conversion ratio. Optimal dietary amino acid levels are dependent on actual raw material price, but also on the price of the specific supplemental amino acid.

Gross margin vs. feed costs

Using dose response data from turkey trials demonstrated that required dietary lysine level was higher for maximising gross margin than for minimising feed cost/kg gain. Another example is based on an experiment where broilers were fed increasing levels of L-Threonine that were added to a Threonine-deficient basal diet from day 21 to 42. Here it was also found that optimising dietary amino acid levels based on gross margin should be preferred compared to feed cost/kg gain simply because the effects of dietary amino acid levels on weight gain are considered in profitability calculations.

Production goal impacts optimum amino acid level

The approach of calculating gross margin to determine the optimal dietary level of amino acids can be extended to a whole amino acid profile. If dietary protein, which has been balanced according to the ideal protein concept, is decreased or increased while maintaining the ratios, dose responses can also be produced and economically assessed.

A trial was conducted using separated male and female chicks of two broiler strains (the versatile Ross 308 and the heavy Ross 708). The birds were fed different balanced protein (BP) levels, which were increased, but the ratios between amino acids were maintained.

Responses on performance parameters after 49 days showed that in both strains and both genders final body weight increased significantly and in a non-linear fashion to increasing levels of balanced protein. Differences between strains were small at recommended or higher BP levels, whereas at lower levels performance depression of Ross 708 was more pronounced.

The rather linear responses on feed conversion ratio were very strong and covered a range of about 15-25 points. Breast meat yield again increased asymptotically, but for this parameter – as expected – a clear difference between strains was observed with higher breast meat yield for Ross 708 broilers. Technical performance data does not suggest different optimum dietary BP levels for the strains despite the higher breast meat yield of Ross 708 broilers.

Response data was taken to calculated gross margin taking typical UK conditions and considering feed and production cost as well as revenues at farm gate and after processing. Farm margin and processing margin characterise two typical production goals of broiler operations. For these calculations bird performances were standardised to 2 kg and 3 kg body weight.

According to equations, optimal dietary BP level was 106% and 102% in male and 97% and 98% in female Ross 308 and 708 broilers to achieve maximal farm margin at 2 kg target weight, respectively. As expected, females required less BP than males. A small difference between strains occurred only in males, which disappeared at 3 kg final weight. In males, farm margin maximised again close to recommended BP levels (104%/103%) suggesting that current recommendations are adequate over a wide range of final weights. At 3 kg market weight, optimal dietary BP levels for maximising farm margin reduced to 85% and 84% of recommendations in female Ross 308 and 708 broilers, respectively, caused by the substantially lower growth rate of female compared to male broilers during the final phase.

Processing margin

When it comes to processing margin, carcass quality profitability of Ross 708 broilers was higher than that of Ross 308 broilers because of the higher breast meat yield. Regarding the economically optimal dietary BP level there was actually no difference between strains both in males and females. So, at 2 kg target weight optimal dietary BP levels were 118% (308 males), 119% (708 males), 106% (308 females), and 111% (708 females). Respective numbers for 3 kg target weight were 115%, 113%, 104% and 106%. In female broilers slightly higher BP levels than currently recommended were suggested by the processing margin equations. In addition, optimal dietary BP levels were substantially higher compared to those found for farm margin. This clearly indicates that production goals of the operation influence the optimal levels of amino acids in broiler diets. As soon as breast meat yield is included in the economic calculations, the economically optimal amino acid level increased.

Feeding program influences production goal

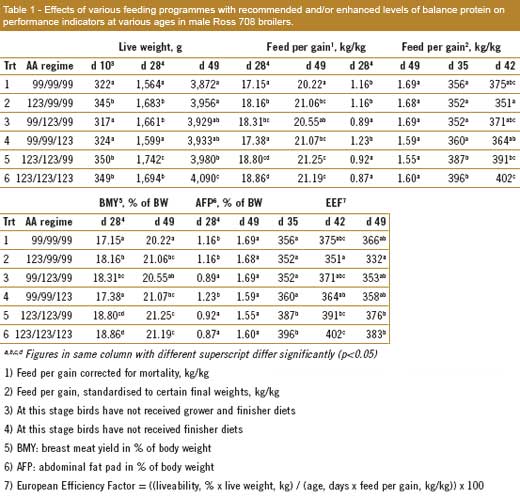

In the same experiment with the male Ross 708 broilers the use of amino acid levels of 99% BP and/or 123% BP in starter, grower and finisher diets were compared. Effects on body weight and feed conversion ratio are shown in Table 1. Higher BP level generally gave superior body weights compared to those on 99%. Feeding the 123% BP diet in more than one feeding phase resulted in significant improvements in all performance parameters, with the best overall performance for all parameters achieved when the 123% BP feed was fed all through. Final weight at day 49 was only numerically increased when 123% BP diets were fed only in one phase compared to the 99% BP control treatment, regardless which phase.

However, with increasing numbers of subsequent phases in which the 123% BP diets were fed, final weight increased significantly. This finding suggests the additive character of feeding increased BP levels in subsequent phases. Feed conversion ratio was also improved by high BP diets particularly when fed in the finisher diet or in subsequent phases. The additive character of the response on feed conversion to enhanced BP was nicely pronounced when feed conversion ratio was related to standardised market weights of 2.0, 3.0, and 3.5 kg.

Breast meat yield and abdominal fat accretion were also affected by BP levels with highest performance when 123% BP was fed in starter and grower or throughout all phases. The European Efficiency Factor (EEF) serves as an indicator for profitability. Data suggest that EEF is not affected when dietary BP is increased only in one phase. However, when fed in subsequent phases EEF improved gradually with highest numbers found in treatment with 123% BP in all feeds.

Farm and processing margins contradict

Experimental data was also used for calculating farm margin and processing. In this case a target weight of 3.0 kg was chosen. In accordance to the economic calculations farm margin was highest when recommended dietary BP levels (99%) were fed throughout the experiment. In contrast to the EEF these calculations are influenced by both price per kg live weight and feed cost. However, processing margin was maximised when 123% diets were fed in the starter plus grower phase. Therefore, processing margin suggests that feeding increased dietary BP levels in subsequent phases is required in order to maximise white meat build-up. The effects of BP on performance parameters in individual phases and their effects on performance in following phases can be of importance in economic terms. This finding complicates the introduction of economically optimal dietary amino acid levels in amino acid recommendations.

Estimation of economically optimal amino acid level can get even more complicated if length of phases is varied or amino acid levels between phases differ. In order to give an idea on economically optimal amino acids in broiler diets in subsequent phases without using a complete broiler model one might simplify those complex interactions. One approach would be further developing tools such as QuickChick giving economically optimal dietary amino acid levels per phase using biological responses and economic key figures per phase. QuickChick is a software by Evonik Degussa providing amino acid recommendations for broilers which are adjusted to various factors, including phase lengths, sex of broilers, pellet quality, and dietary energy level in any of the defined (up to 5) feeding phases.

With the focus on amino acid requirements one should not forget that other factors also impact economically optimal amino acid levels in the diet. Using income over feed cost consider only a few economic key figures. The diet costs themselves will depend on raw material prices, but also production technology; physical feed form (quality) has a tremendous impact on broiler performance. On the other hand it was also suggested that these effects could be compensated in economical terms if poor physical feed quality goes along with reduced diet cost. This article is a condensed version and published with permission from Evonik Degussa GmbH.