Encapsulation processes lead to varying levels of protection

Lipid encapsulation has proven to be a valuable tool to protect nutrients from degradation during processing, storage and digestion, making the nutrients available for absorption by the animal. Over the last five years many new encapsulated products have entered the market. These products, and the processes that create them, differ greatly in design, technology, and unfortunately, performance.

High quality encapsulated nutrients can provide nutritionists with a great deal of flexibility to improve rations while reducing costs. However, all encapsulated products are not created equal. To make the most of the ingredient investment, nutritionists, veterinarians, and producers should recognize differences between the various encapsulation technologies. This will allow users to make informed decisions about which product(s) will be most cost effective in the ration.

Lipid encapsulation is an effective rumen protection technology across a range of different nutrients. However, lipid encapsulation is a generic term and differences exist between products. These differences are due to:

1. The starting form and inclusion rate of the nutrient

2. The coating system utilized

3. The manufacturing process used to produce the lipid encapsulate.

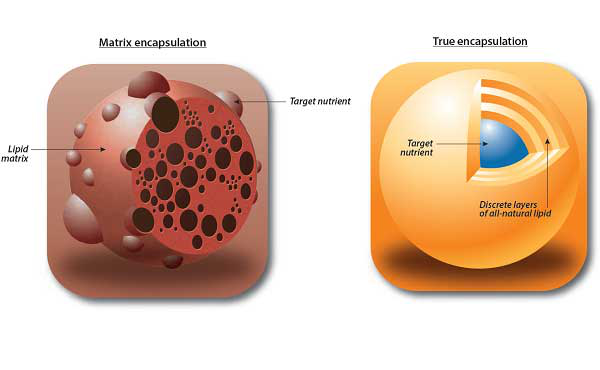

There are two main types of lipid encapsulation technology, true encapsulation and matrix encapsulation. A matrix encapsulation suspends the active nutrient within a fatty acid matrix (Figure 1) while a true encapsulation contains a layered coating of fatty acids applied around the outside of the nutrient to form a protective barrier (Figures 1 and 2).

Figure 2. Micrograph of a true encapsulated nutrient demonstrating the layers of lipid coating surrounding the outside of the active compound to create a protective barrier.

An effective coating technology must provide: 1) Durability, 2) Rumen Protection, and 3) Intestinal digestibility. If any of these functions are compromised then the product will fail to deliver the nutrient as intended.

Durability

Durability is the ability of an encapsulated nutrient to maintain integrity during handling, storage, and mixing. Abrasion of the protective coating, cracking, fracturing or particle size reduction can all reduce the amount of nutrient delivered to the animal. Another often overlooked factor that can affect coating integrity is temperature. Lipid encapsulated nutrients are not robust enough to withstand the temperatures and pressures associated with pelleting. High temperatures designed to gelatinize starch and deliver a harder pellet will melt lipid coating, adversely affecting nutrient payload protection. In addition, the pressure associated with pelleting can crack or fracture encapsulates, further degrading nutrient protection.

A less obvious and often overlooked issue is freeze-thaw stability of lipid encapsulates. When lipid encapsulates are frozen and then thawed the coating can expand and contract (Figure 3). This allows water to penetrate during storage or in the rumen resulting in a loss of nutrient protection (Figure 4). Some of the more established encapsulation companies have solved this issue.

Figure 3. Micrograph demonstrating the damage that occurs to an encapsulated product’s coating during a freeze/thaw cycle if the product is not designed to be stable under freezing and thawing conditions. Notice the red arrows pointing to cracks that develop in the coating’s surface which allows moisture and rumen microbes to enter the coating and degrade the nutrient, thus greatly reducing the product’s efficacy.

Figure 4. Diagram demonstrating the damage that can occur and the resultant loss in rumen protection if an encapsulated product is not designed to be freeze/thaw stable. The “blue bars” signify a product that is freeze/thaw stable and the “green bars” signify a product that is not freeze/thaw stable.

Rumen Protection

Rumen protection refers to the encapsulation system’s ability to protect a nutrient from degradation in the rumen so that it can pass into the small intestine. Degradation rate is determined using time-release studies in either rumen fluid or water (both are highly correlated). Water tests simplify the analytical process since there is no interference from nutrients in the rumen fluid.

The key to making an efficacious encapsulated nutrient is to create a product that not only resists ruminal degradation but can then be released and digested in the small intestine.

Intestinal Digestibility

Developing an encapsulated nutrient with a high level of durability and that resists microbial degradation in the rumen may come at the expense of intestinal digestibility. Can the product be both robust in its ability to withstand manufacturing and ruminal digestion and still have high intestinal digestibility? Yes. But only a few manufacturers have the expertise and experience to create products with all three attributes.

Bioavailability

Bioavailability is the sum of the previous three functions: durability, rumen protection, and intestinal digestibility and is the true measure of a quality encapsulated product. For an encapsulation technology to be truly effective, it must excel at all three functions.

The ultimate measure of an encapsulated nutrient is the cost per unit of bioavailable nutrient. This is a function of the cost, durability, rumen protection, and intestinal digestibility. To get the most for your money ask a few simple questions:

- Is the product durable enough to withstand processing and storage, including freeze-thaw cycles, so that it maintains its ability to protect the nutrient in the rumen?

- Does the product deliver adequate rumen protection over a long enough period of time (approximately five hours) to ensure a high percentage of the nutrient reaches the intestine?

- Has the product been tested in vivo (in the cow) to have a bioavailability value that reflects the durability, rumen protection, and intestinal absorption supported by research?

Ask to see the research and quality specifications to ensure the product you’re considering will deliver the expected levels of bioavailable nutrient to the cow.