Exogenous enzymes: The natural solution to unlocking nutrients

Population growth worldwide is increasing the demand for protein, but production costs are rising, and common feed ingredients are harder to access. While ample nutritional solutions exist, some create as many problems as they address. But what if there’s a solution that boosts hen health and productivity while saving money and protecting the planet?

The highest cost in poultry production is feed, which continues to rise due to a combination of factors including global inflation, geopolitical events, supply chain issues and climate change. Because of this, prices for conventional feed ingredients such as corn and soybean meal remain volatile, driving producers to use nonconventional feedstuffs in diets, especially raw materials that are more locally available.

It is more vital than ever to get as much nutritional value as possible out of your feed, and this means addressing the ways in which precious nutrients may go undigested by your birds.

When regular digestion isn’t enough

A chicken’s small intestine, where nutrients are absorbed, is relatively short. Feed passes through rapidly. Traditionally, this hasn’t been a problem; like all animals, chickens have evolved to thrive on the feedstuffs available. However, with feed now at a premium, producers must amp up what the birds can do naturally, and there is only a small window of time and opportunity to boost nutritional uptake with each feeding.

Plants store energy-providing nutrients as simple sugars, starches, and non-starch polysaccharides (NSPs). These are meant to be converted into absorbable nutrients by enzymes, which are proteins that catalyse chemical reactions. The enzymes disrupt the cell walls in the feed, breaking it down into nutrients the intestines can absorb.

While the simple sugars and starches are readily digested by these naturally occurring enzymes, the NSPs are more of a challenge as poultry simply don’t produce adequate digestive enzymes to break down such complex molecular formations into absorbable carbohydrates very well.

The reasons for this are varied. NSPs can be categorised as insoluble or soluble, and each category poses its own problems. Insoluble NSPs occupy space in the digestive tract that can create a physical barrier against digestive enzymes and nutrients, while soluble NSPs increase the viscosity of digestive tract contents, disrupting the absorption of proteins, lipids and other carbohydrates.

This is a major problem because the NSP content in poultry feed ingredients ranges from about 10–30%, with higher amounts of NSPs typically found in cheaper, non-conventional feedstuffs and agricultural waste byproducts.

NSPs aren’t the only digestive challenges faced by poultry. Fibrous components in feed are also typically more difficult to digest effectively. In addition to reducing feed efficiency, these digestive inadequacies cause health problems in the birds. Undigested feed in the hindgut provides more opportunities for bacteria, including the dreaded Salmonella, to proliferate, and it causes the formation of excess gas with a high pH, which can lead to tissue damage. Serious and even fatal conditions such as necrotic enteritis can result. Also, because of reverse peristalsis – an ability that, in the absence of harmful bacteria, amplifies digestion – these harmful caecal contents can travel back through the digestive tract, breaching its integrity and seriously hindering performance.

The solution is evident: to supplement the birds’ existing enzymes with exogenous enzymes developed to augment these natural processes.

The benefits of Allzyme Spectrum

Diet composition, NSP diversity and variability will help determine which enzyme solution is right for each production. Multiple substrates require multiple enzymes, so it is crucial to look at the overall poultry diet instead of focusing on single ingredients. Choosing an enzyme complex that targets multiple substrates gets the most out of the complete diet.

Following intensive research over the past few years, Alltech has improved its enzyme technology even further with the introduction of Allzyme Spectrum, a next-generation multi-enzyme complex that maximises nutrient utilisation by breaking down multiple fibre substrates in the diet.

Allzyme Spectrum:

- Drives energy return and phosphorus release

- Promotes optimal digestion and nutrient absorption

- Optimises feed cost savings

- Decreases excess nutrient excretion into the environment

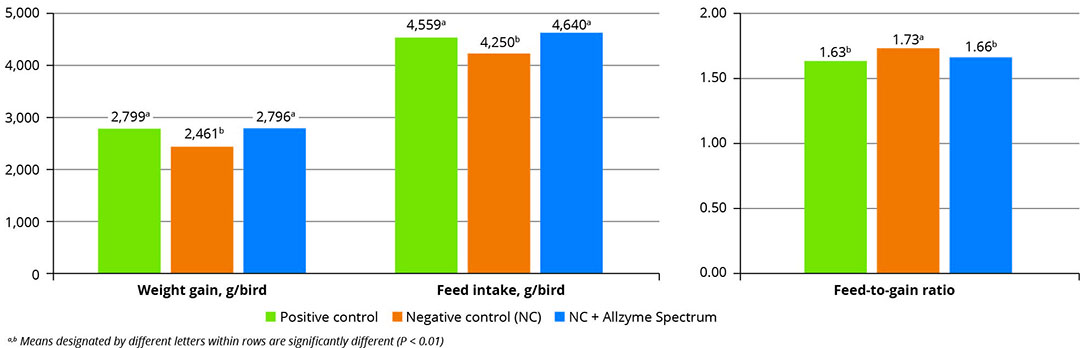

Figure 1 – A low-nutrient diet with Allzyme Spectrum added was equal in performance to a commercial diet.

Proven by research

Allzyme Spectrum, developed in Alltech’s renowned Center for Animal Nutrigenomics and Applied Animal Nutrition by researchers with in-depth experience in fermentation in animal nutrition, has proven its safety and effectiveness not only in the lab but in university trials and, of course, on-farm. All of this research has shown that Allzyme Spectrum can save 90 calories per kilogramme of feed in poultry diets. This allows birds to use the extra energy to grow more efficiently and gives nutritionists the flexibility to include nonconventional feedstuffs in diets, helping producers save money.

Recent broiler research with corn-soy and wheat-soy diets showed that a low-nutrient diet with Allzyme Spectrum was equal in performance to a commercial diet (Figure 1). In addition, all 3 levels of Allzyme Spectrum tested in broilers showed performance equal to the commercial standard at 22 days (Table 1).

Beyond the birds: environmental protection

The damage done by inefficient digestion is not confined to the animal or even to productivity and profitability. Undigested feed and the bacteria that go along with it are eventually excreted, causing environmental challenges both on-farm and in a larger sense. They lead to significant pollution of our soils and waters.

Sustainable farming practices will continue to play a vital role in helping the agri-food community keep up with the dietary demands of our growing population. Innovative nutritional solutions – including multi-enzyme technologies like Allzyme Spectrum – can improve the productivity and profitability of animal production while also providing significant sustainability benefits.

* References are available upon request.