Grinding barley-rich pig feed with hammers and rollers

Particle size in pig feed matters. This article describes how the particle size structure of a pig feed mixture with a high barley content can be optimised by means of stage grinding with a hammer mill and a downstream crushing roller mill.

Animal nutrition research findings have shown that an increased content of fines in the pig feed meal can have a negative influence on the health and performance of the animals. This is caused by the formation of gastric ulcers in the animals, by a non-optimal pH-regime in the stomach and by health problems caused by pathogens in the gastrointestinal tract. From the technical point of view, a non-uniform particle size spectrum leads to segregation and a high fines percentage to poor flow properties in the silo.Almost all feed mills are traditionally equipped with hammer mills which are mainly used in mixed grinding. Despite the use of stage grinding with pre-/post-mill and intermediate screening, it is not possible to keep the fines content at an acceptable level. In flour (roller)milling, crushing of wheat and rye with a low fines content in the first grinding stage is known. If, however, only roller mills are used for grinding of pig feed, problems occur with crushing the husks of barley or oats. Very early on it was realised that stage grinding with a roller mill in the second grinding stage is more suitable for grinding barley.Therefore, it is necessary to find a compromise that combines grinding with a low fines content by means of rollers and crushing by means of a hammer mill suitable for crushing husks. For this purpose, a compound feed manufacturer and German feed equipment builder, Amandus Kahl, initiated a project that was conducted by students of the German Milling School Braunschweig with the aim of producing pig feed rich in barley with a low fines content (max. 25% <0.5 mm) and at the same time sufficient crushing of the husks.

Trial setup

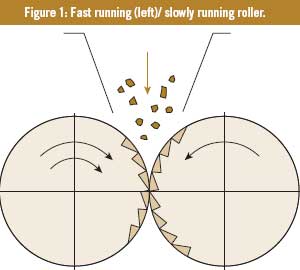

In order to determine the influence of different crushing machines and grinding systems on the feed structure, a typical pig feed mixture was designed containing barley, approx. 30%, rye, wheat, soybean meal, rape meal, mill by-products, and premixes.The “natural” content of fines of <0.5 mm in the mixture prior to grinding was approximately 5%, due to additives and fines of the individual raw materials. All measurements of the fines content which will be referred to later were made with the final mixture from the batch mixer.Hammer mills and crushing roller mills were used for crushing. The operating mode of hammer mills is known. Crushing roller mills are roller mills which are meant to break the grain into smaller particles with an as low as possible fines content. Thus, granular crumbles with low fines content are to be produced instead of meal. For this purpose, the crushing rollers (Figure 1) are provided with a “sharp to sharp” (S:S) corrugation. The rollers have different circumferential speeds so a cutting effect is obtained instead of a crushing effect. The speed of the rollers and the lead are usually firmly adjusted, however, speed modification and a change of the lead during operation would be ideal.The particle size obtained with the crushing roller mill (Figure 2) is determined among others by the corrugation/circumference, the lead and the grinding gap. If the formulae are frequently changed, an automatic grinding gap measurement and remote adjustment of the roller distance are advantageous. It is important that the rollers are fed over the entire width by a suitable feeding device to achieve a uniform load of the rollers and the highest possible throughput. Which grinding machines were used are illustrated in Table 1.

Four variants were chosen for the study:

- BWS Crushing roller mill, (two stages/twice) without intermediate screening.

- HM + HM= Stage grinding: hammer mill, with pre-mill / post-mill and intermediate screening.

- HM + BWS = Stage grinding: hammer mill + crushing roller mill (one stage) with intermediate screening.

- HM + LMW= Stage grinding: hammer mill + laboratory grinder with intermediate screening.

The variant crushing roller mill + hammer mill with intermediate screening (BWS+HM) was not part of the comparison. Preliminary tests had similar results for crushing of husks using the arrangement hammer mill – crushing roller mill (HM+BWS) which provides better results than the reverse order. A hammer mill in the second grinding stage produces more fines than a hammer mill in the first grinding stage.

All tests were conducted under practice conditions and with high throughputs, except for the test with the combination HM + LMW. In this case, the product was crushed at a high capacity in the first stage, and subsequently a part of the material was post-crushed on a laboratory grinder.

Results

To assess the crushing results, particle sizes were rated fine (<0.5 mm), medium (0.5 to 1.6 mm), coarse (1.6 to 2.0 mm) and very coarse (> 2.0 mm). The aim was to obtain a maximum accumulation in the medium range with a medium grain size of 1.0 – 1.1 mm. The percentage of fine particles should be as low as possible and not exceed 25%. In this context it has to be pointed out that the indication “medium particle size” does not imply any information on the percentage of fines <0.5 mm in a mixture. Therefore the definition and determination of the medium range, for example 0.5 to 1.6 mm, are to be preferred.The arrangements of the machines and the results obtained with the different crushing variants were as follows:The result shows that the fines content is lower than 25%. Yet, there is a percentage of about 20% in the “very coarse range” although this does not have to be considered as negative. The structure is relatively broad. As there is no intermediate screening and no post-crushing, the coarse fraction mainly consists of husks. Though a large screen perforation in the pre-mill and a low circumferential speed have been selected, a very high fines content is produced.

With this variant a very good result is achieved which meets the objective in every respect. The percentage of fines <0.5 mm is lower than 25% and the “very coarse” fraction is below 5%. Thus the largest fraction lies in the medium particle size range. Hence, the product has a relatively narrow structure, which is uniform in appearance. Variant 4 is a further improvement of variant 3 due to the modification of the lead and the adjustment of the circumferential speed of the rollers. That adjustment was not possible with the existing crushing roller mills which were used. Of course, a corresponding system can be retrofitted. The variant shows that by means of adjusting the circumferential speed of the rollers and the lead, the grain structure can easily be optimised.

Energy consumption

In all variants, the electric energy consumption in kWh/t was determined by measuring the effective power and by meter reading. The results are not presented in detail in this article. Generally, it can be stated that the electrical energy consumption of the variant with two crushing roller mills is about 50% lower than that of the variant with two hammer mills; and that of the variant hammer mill + crushing roller mill is about 30% lower than in the variant with two hammer mills.

Conclusions

To provide a better overview, the grinding results of the variants 1 to 3 are represented in an undersize cumulative distribution function. Especially the comparison with the distribution density shows which variants ensure low fines content (Figure 2).

The following conclusions can be drawn:

- Grinding using a BWS or HM+BWS causes a significantly lower fines content compared to crushing using HM+HM. The intended set point value of max. 25% <0.5 mm could be achieved in all variants.

- The highest percentage in the medium-size particle spectrum is achieved by stage grinding with HM++BWS.

- By increasing the lead of the crushing roller mill, the results can be further optimised. Therefore it is recommended to provide for speed adjustment during operation.

- When a hammer mill and crushing roller mill are used, the grain structure is more uniform and therefore less prone to segregation, while the flow properties are improved. The outward appearance also suggests a homogeneous product, in particular on account of the high concentration of particles in the medium particle size range. The barley husks are sufficiently crushed.

- The tests have shown that the specific energy consumption can be reduced significantly by using the crushing roller mill.

- Contrary to hammer mills, crushing roller mills do not require aspiration air at all or only a small quantity if a destoner is installed, for example. The expenditures for fulfilling the ATEX safety requirements will be reduced accordingly.

- When a crushing roller mill is used, the savings in terms of energy costs are significant compared to that of the hammer mill.

Future prospects

The present article shows that by installing crushing roller mills in new or existing compound feed plants, the feed structure of pig feed rich in barley can be improved considerably, while the electrical energy consumption is reduced significantly.

Coarse barley husks can be reduced also by means of upstream pelleting of the grain using a flat die pelleting press with subsequent mixing before the treated barley is fed into the mixed grinding section.

Tests in the pilot plant have shown that in pan grinder mills (modified flat die pelleting press) the husks are de-fibred transversely and not longitudinally as in the case of hammer mills and above all crushing roller mills. With Schule whitening machines, type VPC, it is possible to grind the husks off the whole grain to a certain degree. An alternative use of the ground off and separated husk fraction should be considered.