Heat stable phytase shows greater efficacy

To enable pig and poultry producers to continually improve production efficiency, Danish company Danisco developed a new generation phytase by using Thermo Protective Technology (TPT). Dr Ceinwen Gilbert xplains the benefits.

Whereas the first major phytases in commercial use were derived from different species of fungi, a new-generation product in the market, Danisco’s 6-phytase Phyzyme® XP, is derived from a bacterial source. Such new generation phytase products will play an increasingly vital role in helping pig and poultry producers to stay ahead of tightening economic pressures and environmental standards by reducing feed costs and minimising waste. However, to maximise the potential benefits offered by new generation phytases, it is vital to fully appreciate, and account for, their greater efficacy compared with traditional phytases when formulating pig and poultry diets.

More effective

Research conducted by numerous research centres and universities across the world have demonstrated this product as being substantially more effective than a traditional phytase product in broiler, layer and pig feeds. In broilers and pigs fed phosphorus and calciumreduced diets supplemented with the same dose of phytase to market age, the new-generation phytase was 44 – 47% more effective at increasing bodyweight gain and 65 – 73% more effective in improving feed conversion. These improvements were due to the superior ability of the new-generation phytase to liberate phosphorus and calcium from dietary phytate and reduce the antinutritive properties of dietary phytate. The same trends have also been confirmed in layers and turkeys. To fully embrace the greater potential of this new-generation phytase, poultry and pig producers can make greater reductions in dietary inorganic phosphorus, energy and amino acids, increasing net savings by at least US$1.20 (€1.00) per tonne of feed compared with using traditional phytase products, giving a gross feed cost saving of about US$4.50 – 6.50 (€4.00 – 5.00) per tonne of feed.

Pelleting issues

To avoid the potential complications associated with post-pelleting liquid enzyme application systems, proven enzyme heat stability remains a key requirement for the feed industry to allow direct enzyme addition through the conditioning/pelleting process. Thermo Protection Technology (TPT) delivers a free-flowing, dust-free phytase granulate product that maintains efficacy even after exposure to feed conditioning and pelleting temperatures of up to 95°C (203°F), allowing effective use of this dry product in the majority of feed manufacturing processes. Thermo Protection Technology applies a coating to the phytase enzyme that delivers unrivalled protection against the high temperatures that typically occur during the feed pelleting process, while still rapidly releasing the enzyme activity where needed in the animal’s gut.

Heat stability

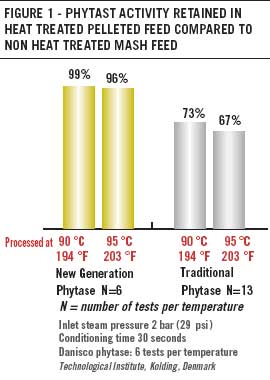

Independent trials conducted by the Technological Institute at Kolding in Denmark to investigate the effect of TPT on the heat stability of the new-generation phytase demonstrated consistently good results. The coated phytase was included in the feed prior to conditioning and pelleting at temperatures of 90°C (194°F) or 95ºC (203ºF) and with a conditioning time of 30 seconds. Relative to unprocessed mash feed, 99% of the phytase activity remained after conditioning and pelleting at 90°C (194°F), whilst at 95°C (203ºF) 96% of the phytase activity remained. In sharp contrast, when comparing the heat stability of this coated new-generation phytase with another commercially available traditional phytase (claimed to have similar heat stable properties) approximately 25 – 30% more phytase activity was lost from the traditional phytase product after conditioning and pelleting at these high temperatures, reducing the level of phytase activity to 73% and 67% respectively (Figure 1). Numerous pelleting trials comparing the heat stability of the coated new-generation phytase with three other commercially available heat-stable phytases also showed that the new-generation product retained approximately 20 – 55% more phytase activity at 90°C (194°F) and approximately 25 – 65% more phytase activity at 95ºC (203ºF). Animal trials have confirmed that the new-generation phytase releases effectively in the intestine, with no detrimental effects on phytase efficacy in the animal. Broiler studies conducted by the Agricultural Development and Advisory Service (ADAS), UK, and at the University of Manitoba, Canada, confirmed no significant differences in liveweight gain, feed conversion ratio (FCR) or tibia ash in birds fed either the uncoated or coated phytase, confirming that the coating allows the phytase to be released effectively in the bird’s gut (Table 1).

Multi-factorial model

To calculate customer-specific matrix values for phosphorus, calcium, amino acids and energy according to the level of dietary phytate phosphorus, phytase dose rate and economic considerations, the company uses the software programme Phycheck™. This service was developed from extensive digestibility and performance trials conducted in North and South America, Europe and Australasia that contributed a total of over 100 individual data points each for broilers, layers and pigs. The optimisation service employs a “multi-factorial model” to describe animal responses to phytase based on these trials, for example improvements in energy (AME) and amino acid digestibility, according to phytase dose rate (250 – 1000 FTU/kg feed). For broiler and layer feeds, the effect of dietary phytate phosphorus level (0.23% – 0.33%) is also accounted for, as is the effect of bird age in broilers (0 – 21 days or 22 – 42 days).

The model indicates improvements in dietary energy (AME), ileal protein and amino acid digestibility at all phytate concentrations. There are also significant interactions between phytate level and phytase dose rate. The new software takes account of these complex inter-relationships when calculating the specific matrix values for phosphorus, calcium, amino acids and energy for a specific diet.

In today’s challenging and increasingly competitive market, pig and poultry producers throughout the world can benefit from this advance in phytase optimisation. Feed producers under pressure to maximise feed cost savings can now confidently apply phosphorus, calcium, energy and amino acid matrix values, thereby fully exploiting the cost-saving potential of the new-generation phytase, without risking animal performance. As phytase use continues to grow throughout the world and product choice becomes more diverse, so does the need for reliable tools to enable feed producers to compare and optimise phytase use for maximum economic benefit.