Managing water activity for safer animal feed

Feed safety is of utmost importance as it not only impacts animal health and performance, but could also impact the health of consumers. Therefore, a comprehensive feed hygiene and microbial monitoring programme must be developed for the entire feed chain. Moulds have the potential to produce secondary fungal metabolites called mycotoxins. Even low levels of mycotoxins have a detrimental effect on animal health and performance as they accumulate in the liver and lungs.

There are many factors that influence bacterial and microbial growth, such as pH, oxygen levels, temperature, and the amount of free water.

The analysed moisture content of feed describes the total water content of the product. The total water content is comprised of free water and bound water. Free water is water that is not bound to feed particles and can move freely in and out of the feed. This free water is available to microorganisms for growth. Water activity is a ratio between 0 and 1 which describes the amount of free water in feed, and can be used to determine the risk of spoilage due to microbial growth.

Without intervention, the moisture content of the raw materials included in a feed determines the moisture content of the formulated feed. Changes in ambient temperature and humidity cause water to migrate during storage creating condensation resulting in increased free water and thus higher feed water activity.

Managing the water activity of feed

The moisture content of the feed assists in starch gelatinisation and palatability. It is, therefore, not desirable to reduce moisture content in feed. Moisture in the feed that is bound is not available to microorganisms for growth. Reducing free water, and therefore water activity, will hinder growth of most bacterial pathogens when the water activity of a feed falls below 0.9, and below 0.6 for most moulds.

Bacterial pathogens and moulds have adverse effects on animal health and performance with potential economic consequences. It is important that these organisms are controlled from pre-harvest through to feed consumption on farm. Bacterial pathogens and moulds are tricky to manage as they are widespread and cannot be eliminated entirely. Heat-treatment steps can kill bacterial pathogens such as Salmonella, but mould spores are stable and won’t be destroyed. This has necessitated the need for alternative solutions. By managing the water activity of feed during processing and storage, we can reduce the proliferation of microorganisms and thus ensure feed safety.

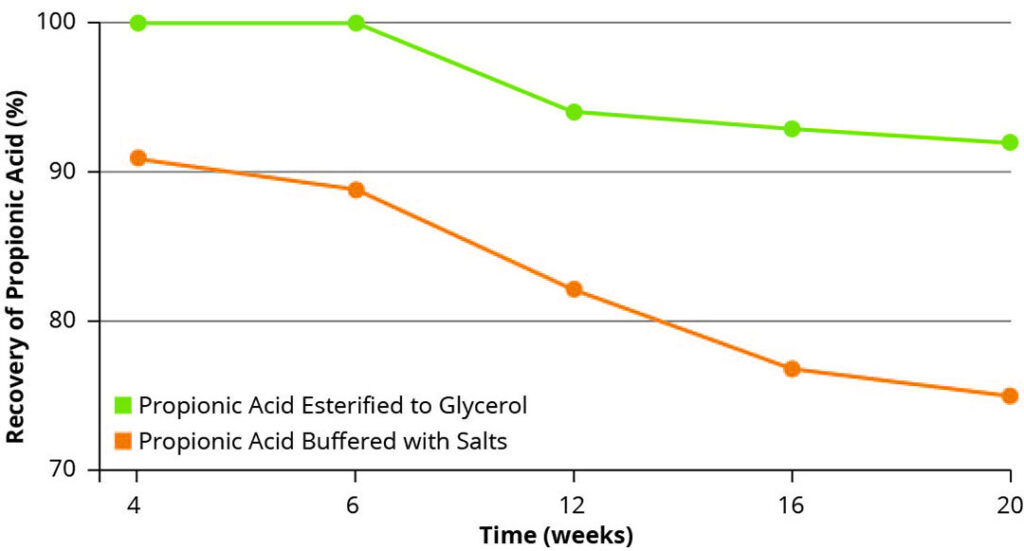

Figure 1 – Stability of propionic acid in different chemical forms.

Organic acids against mould

The use of organic acids as preservatives is well researched. Propionic acid is one of the most effective organic acids against mould growth. Multiple modes of action target specific microorganisms;

- the acid accumulates in the cell of the microorganism and competes with amino acids needed for growth,

- propionic acid inhibits enzymes needed for metabolism,

- undissociated propionic acid molecules penetrate mould cell walls, destroy the cell membrane structure and acidify the cytosol, inhibiting growth and killing the cell.

Organic acids effectively suppress mould and bacterial pathogen growth. They maintain the nutritional value of feed as well as improve nutrient digestibility. They make a fundamental contribution to feed hygiene and safety, animal health and performance.

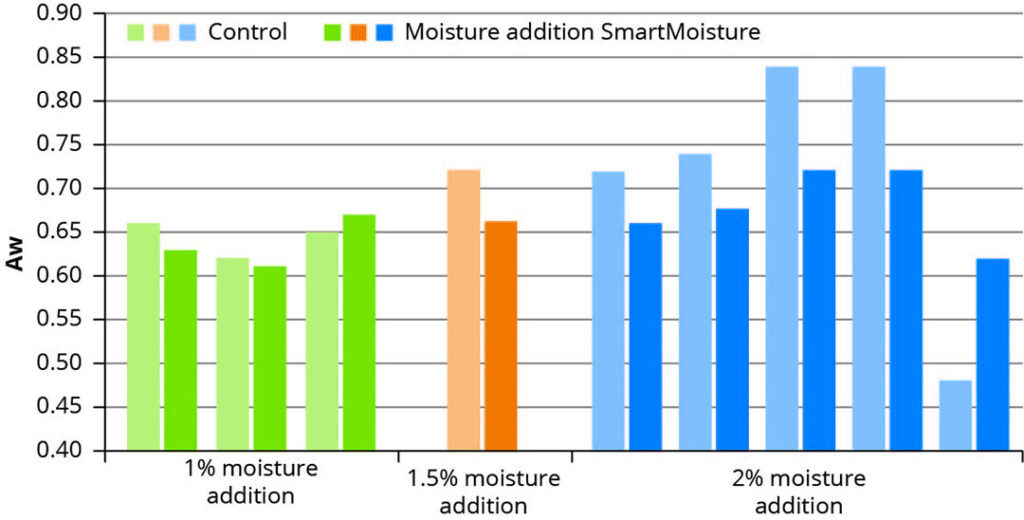

Figure 2 – Water activity levels of various trials.

Feed safety

Moisture management is imperative in maintaining the moisture content of feed while reducing water activity. Animal feed can lose up to 2% moisture during storage and processing. Shrinkage and milling loss can lead to considerable financial losses for feed manufacturers. Untreated water cannot safely be added to animal feed during processing as it will not be optimally absorbed by feed particles and can be easily driven off. This can create problems such as feed build-up and excess free water. Devenish has developed a moisture management product, SmartMoisture, to assist feed producers with these issues.

Typical preserving acids for animal feed include propionic and formic acid. These acids are buffered by binding them to salts, particularly ammonia to form ammonium propionate and ammonium formate. The type of bond determines the strength and stability of the acid, and thereby how long it remains in the feed functioning as a preservative.

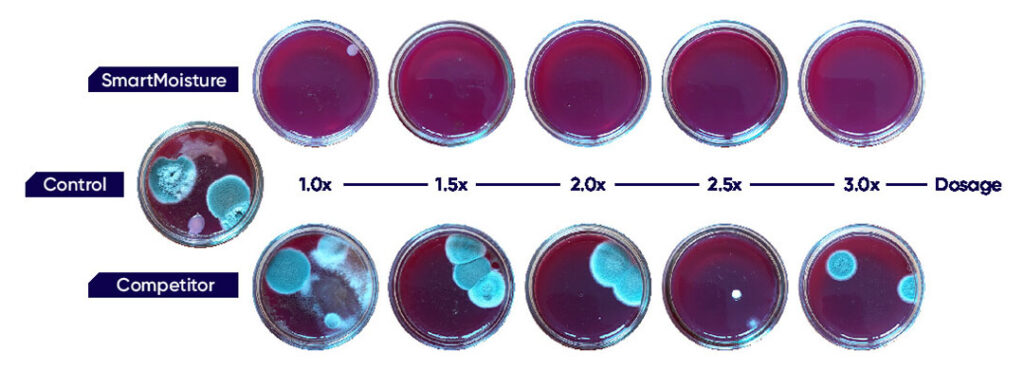

SmartMoisture is a patented product that consists of a combination of propionic acid, propionic acid esterified glycerol, buffered formic acid, and surfactants. The surfactant reduces the water’s surface tension, which improves moisture distribution. Glycerol and the surfactant improve water absorption into feed particles, which helps reduce water activity. The core ingredient, glycerol esters of propionic acid, forms a stable covalent bond. The propionic acid esterified to glycerol is created through a novel process used to buffer and stabilise propionic acid. The esterified propionic acid is slowly released from glycerol by hydrolysis, increasing the retention time of propionic acid in feed, and ensuring longer-lasting microbial inhibition (Figure 1 and Figure 3).

Figure 3 – Mould inhibition. Product A: SmartMoisture, Product B: branded mould inhibitor containing ammonia propionate and ammonia formate.

In a pilot study to determine the benefit of glycerol esterified propionic acid, agar plates were inoculated with increasing strength of 2 mould inhibition products and exposed to air. After 2 weeks, the superior activity of esterified propionic acid was evident (Figure 3).

Increasing moisture content with added product inclusion reduced water activity in the majority of trials (Figure 2). In 2 trials, where the moisture content of treated feed was considerably higher than the control and increased Aw would be expected, water activity was nevertheless controlled below threshold limits.

In extruded feed production for aqua and pet food, trials have demonstrated the ability to stabilise water activity at low levels with increased moisture content. In aqua feed a water activity of 0.55 was achieved with a 4% increase in moisture content.

Effective moisture management is crucial in controlling water activity. The ability to reduce water activity, increase both the level of propionic acid and the length of time it is actively maintained in the feed, inhibits the growth of microorganisms. This ensures good feed hygiene and safety, as well as animal health and performance.