Maximise dairy cow profits with precise use of yeast probiotic

Precision feeding is a concept in which individual dairy cows or groups of cows, with similar nutrient needs, are fed according to their current requirements with a minimal loss of nutrients and maximum utilisation. This enhances sustainability, reduces environmental waste, and optimises on-farm profitability.

Precision feeding is about delivering customised diets to cows, according to their milk production, stage of lactation and life cycle needs.

The advantages of precision feeding are well recognised, but they also come with certain disadvantages. Precision feeding requires the proper allocation of animals into groups, based on their specific nutrient and energy needs. It also means mixing several different rations for each group, which creates additional work for the farmer. While this may be achieved in large dairies it is quite difficult for many typical European farms.

Robotic milking systems

However, with the expansion of robotic milking systems in Europe, more opportunities for precision feeding are being presented to farmers. While in conventional milking parlours cows are commonly fed a total mixed ration (TMR); in robotic milking systems most concentrates are provided individually by the robot during milking, according to each cow’s specific needs and milk production. Cows are still given forage in their diet, alongside some concentrates, as partial mixed ration (PMR). However, they receive a large part of their energy and protein requirements from pelleted feed through the milking robot, which gives better balance to the diet.

While robotic milking systems present some challenges, they also create an opportunity for more frequent milking times, alongside feeding cows more precisely, according to their individual nutrient requirements (A. Bach 2017). Robotic milking systems are advancing rapidly, becoming more precise and solving many former disadvantages. This is creating new possibilities for precision feeding on an individual cow basis, resulting in the improved optimisation of nutrients that may lead to more sustainable dairy farming. The number of existing farms switching to milking robots is increasing every year. According to data from 2020, 17% of dairy cows in Europe are milked by robots while about 50% of new milking parlours use robotic systems.

Feed additives

The precise distribution of nutrients to cows is key to sustainable dairy farming and good cost optimisation. But what about feed additives?

Feed additives are already mixed into a PMR or included in pelleted feeds, as delivered by the robot. They are also mainly given according to a cow’s individual nutrient requirements. However, for some specific additives, such as probiotics and postbiotics, which are becoming more and more essential, this may not be the case. Phileo by Lesaffre have investigated the effect of different doses of yeast probiotic to cows according to their feed intake, milk production, stage of lactation, and stress factors, such as heat stress.

Study results, gained under different conditions and with different diets, show that the adaptation of dosage to a cow’s individual needs significantly improves performance and boosts on-farm profitability.

Actisaf dose adaptation from science to farm

A study of the mode of action of the yeast probiotic Actisaf on rumen formation shows that an increase in dosage produces a significant improvement in rumen parameters.

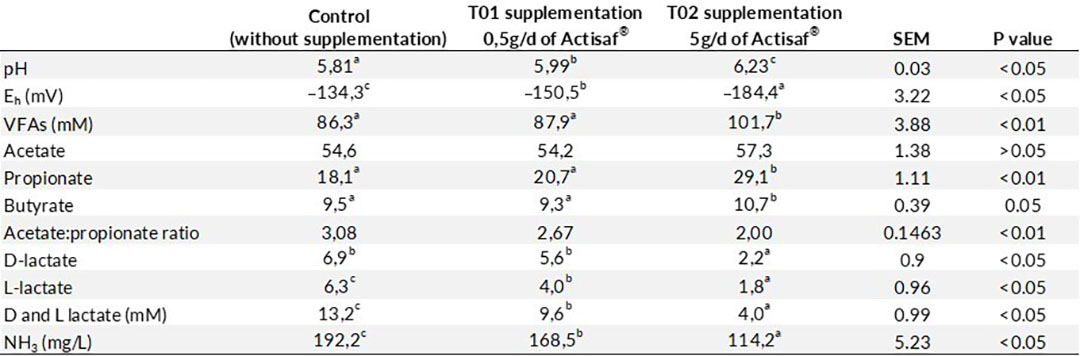

Table 1 – Effect of precision supplementation of Actisaf Sc47 on the physicochemical parameters of the rumen.

Pinloche et. al. 2013

This in vivo titration study shows that Actisaf modifies ruminal fermentation, even at very low dosage level. As the dosage increases, however, we start to see more significant changes. Several studies, carried out in transition cows, demonstrate that an increase in the dosage of probiotic yeast during transition can help to mitigate the adverse effects of a negative energy balance, while also helping to increase milk production. The effect of the increased dosage becomes even more important when the animals are facing challenges such as calving, dietary changes, heat stress and more.

Dosing with probiotics in a robotic milking parlour can be done with pelleted concentrates. In this case, the cows will receive a dosage that matches their milk production, according to the quantity of supplemented concentrate which is being fed. While this is a good start to suppling an adequate amount of probiotics, it is still not optimal. For example, a fresh cow will eat less concentrate but will benefit from being supplemented with higher dose of yeast probiotic for optimal performance.

Additive dispensers

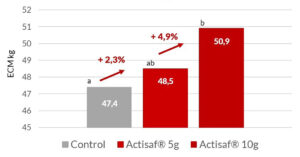

Another way to supplement probiotics, according to lactation and productivity, is through additive dispensers, installed on the milking robot. These dispensers are equipped to supplement different ingredients individually, at a required dosage. For example, in a study with early lactation dairy cows in a robotic milking system with additive dispensers, we delivered 2 different doses of Actisaf, 5g and 10g (Figure 1). Evaluating the resulting performance, we observed a significant difference between the two supplementations, highlighting the need for precision supplementation, at least for early lactation animals.

Figure 1 – Effect of precision dosing of Actisaf on energy-corrected milk (ECM) yield, during early lactation in high producing cows.

Controlled study on a commercial farm with 117 early lactation, multiparous cows, grouped in triplets.

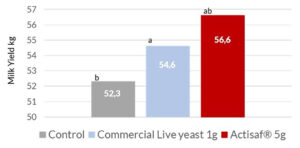

In another study the effect of different commercial dosage levels was compared in dairy cows at different stages of lactation. Field trials were performed comparing recommended doses of 1g and 5g of yeast probiotic under a robotic milking system with additive dispensers (Figure 2).

We also observed the benefit of precision supplementation of recommended doses of yeast probiotic to different groups.

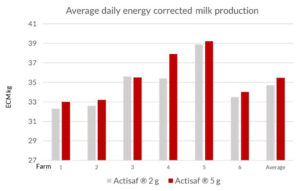

A field trial performed with one of Phileo’ s partners, Vilomix Denmark, involving 6 dairy farms showed the importance of precision supplementation. The differences between 2g Actisaf and 5g Actisaf were studied (Figure 3).

A positive trend was observed, with an increase of 2% on average across the farms and an improved ROI of 5:1, achieved when supplementing Actisaf Sc 47 at 5g vs 2 g/head/day.

The right yeast probiotic dosage

Identifying what the animals needed and supplementing the yeast probiotic Actisaf according to their individual requirements, through robotic milking dispensers, may be beneficial, resulting in improved on-farm profitability. Currently, Phileo is performing numerous trials under different conditions to enable us to give advice on the best dosage of yeast probiotic depending on feed intake/milk production, diet, lactation stage and so on, all designed to optimise ROI.

References are available on request.

Author: Valentin Nenov, Phileo by Lesaffre Global ruminant manager.