Net Energy: The next big leap in poultry nutrition

With the use of Net Energy values in feed formulation up to 30% energy can be saved in poultry diets.

The global animal nutrition industry is moving rapidly towards precision feeding. This is all about retrieving the most accurate nutritional values to better match the needs and better predict how animals react to the formulated diets. Having the most accurate data available is crucial in times with high raw material prices and the increased use of by-products and alternative feed ingredients in poultry diets. Wasting or overfeeding nutrients only makes feed costs rise. And energy is one of the most important parameters of the diet. In this article we explain the benefits of using Net Energy (NE) values over Metabolisable Energy (ME) values to better predict poultry performance and thus optimise broiler diets and production efficiency.

Energy flow losses

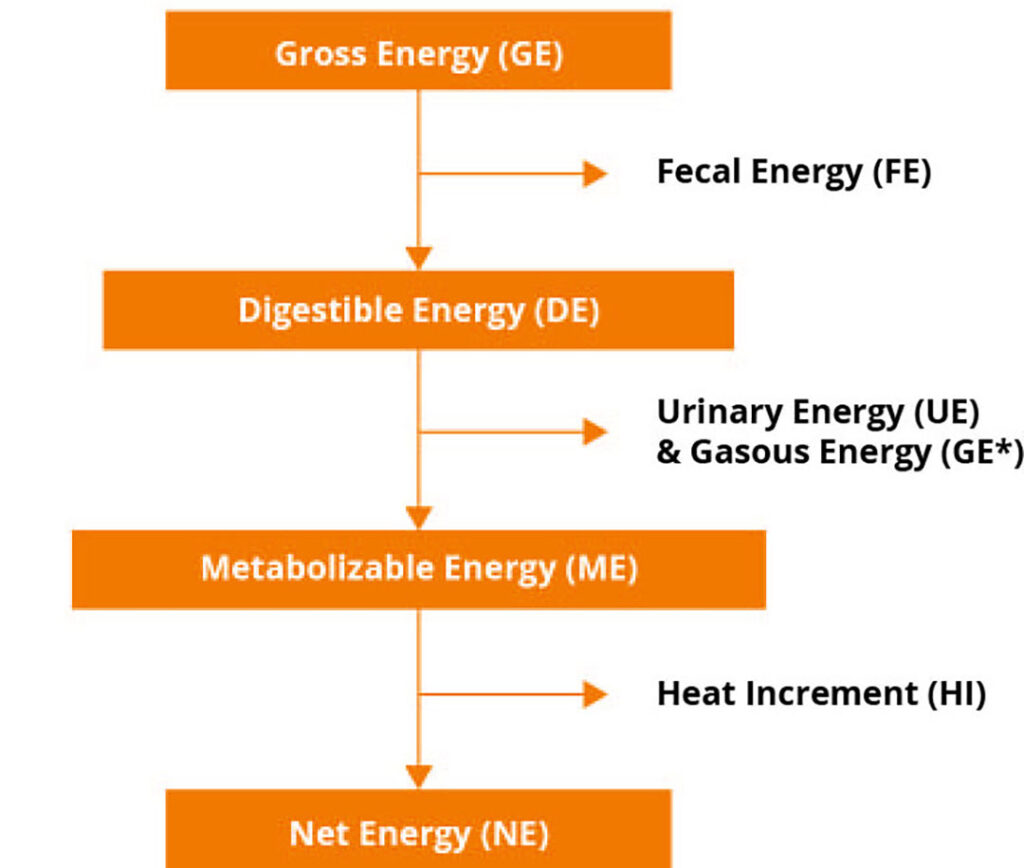

Protein, fat and starch all provide energy to the animal, for maintenance, growth (meat) and eggs. These nutritional values can be based on feed tables or feed analysis (such as the NIR technique used in the PNE service). Over the years, we have moved to Metabolisable Energy (ME) in poultry feed formulation for instance and we use digestible amino acids instead of crude protein. ME is the amount of energy in the feed minus the energy lost in the faeces and urine. But the heat production through digestive and metabolic processes (the so-called heat increment), is still not included in this value. To be more precise and not overfeed valuable nutrients, it is recommended to make the next accuracy step and use the Net Energy (NE) values. NE values can be calculated from the ME values. The transformation of GE to NE can be described by three steps as shown in Figure 1. Adisseo, a global leader in animal nutrition solutions, which backs the adoption of the NE system for poultry, dedicated a full day to this topic during the World Poultry Congress 2022. During live round table discussions with global poultry experts, a practical demo on how to calculate NE values and a Q&A session, this new topic for poultry nutrition was put in the spotlight for the global poultry community.

Figure 1 – The energy flow diagram.

Poultry follow pigs

In the feed industry, all sorts of energy evaluation systems are used, and using NE values is not new. These values have already been common in pig feed formulation for many years and are widely adopted (mainly) in Europe. The reason for adoption by the pig sector has been spurred by competitiveness and the introduction of more by-products in pig diets in the 1980s and 90s. Ever since, the use of NE values in pigs has been successful and shown to be valuable, validated and robust. Now, with the high feed prices and more different feed ingredients used and available for poultry, we need to be more accurate. With NE values we can improve poultry performance and reduce feed costs to remain profitable and competitive.

More poultry data available

The benefits of using the NE system is that it is the most efficient system to address the nutritional value of feedstuffs while expressing the animal requirements. “NE values are more accurate, and they allow us to reduce feed costs and better predict the responses of the animal to diet changes,” said Prof. Mingan Choct from the University of New England in Armidale, Australia. “If you look at the energy flows, there are energy losses with each step. From GE to ME there is 30% energy loss, but from ME and NE there is another 20-30% loss of energy. We cannot continue to afford this. We also see differences in heat loss for different feed ingredients. This is why the NE values are so important. It is the most accurate way to rank and use feed ingredients. There is simply nothing to lose by formulating poultry diets according to NE values. But it takes time to adapt,” Prof. Choct said. Prof. Shu-Biao Wu, who is affiliated with the same university, has been working on NE equations and said: “NE values have been used in pigs and ruminant nutrition for many years. They are simply a more accurate way to assess the growth of the animals, so why not use them in poultry? This is why we worked on more data around heat increment in poultry that allow us to create the equation to measure NE values in poultry.” Jean Noblet, one of the founding fathers of NE application in pig nutrition and ex-INRAe explained: “Convincing the pig industry to adopt NE was rather easy in most countries, as it was easy to implement and allowed the push for low protein diets for example, which was high on the agenda regarding nitrogen losses. Now it is time for poultry because poultry diets are becoming more diverse as well in terms of the ingredients used.”

Easy calculation of NE values

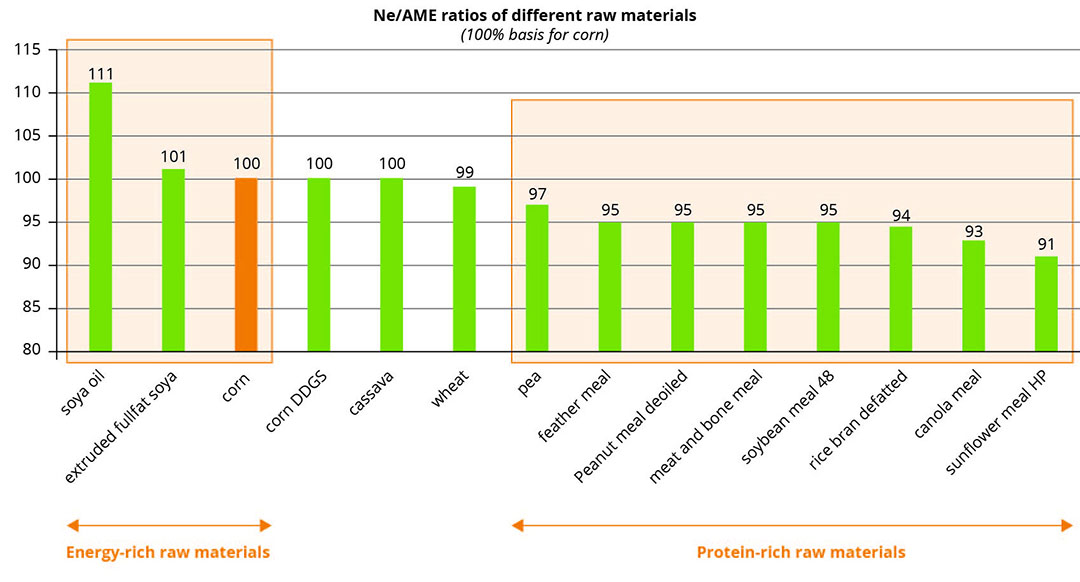

More available equations and long-standing knowledge of feed formulation has allowed Adisseo to develop an online tool (called NESTOR) to provide recommendations for NE for poultry and pigs, alongside recommendations on digestible amino acids and minerals. Pierre-André Geraert, Director of Scientific Marketing at Adisseo explains: “We want to make it easier for nutritionists to work with NE values, so we created this easy-to-use tool. But we understand that change doesn’t come overnight, and formulators need to become more familiar with the values and do the exercise. Are they lower or higher than the energy values I used to work with and what are the differences in the diets regarding nutritional values and type of ingredients? It is a different mindset that needs time and education.” Jaap van Milgen, scientific research director at INRA addressed the fact that “nowadays it is much easier to work with NE values as we can calculate them from the ME values.” According to Céline Gras, feed formulation expert at Adisseo, the NE calculations in NESTOR clearly show the consequences in feed formulation and provide a new hierarchy of feed ingredients in terms of energy and protein (see Figure 2). “When we run different formulations with NE values and different price scenarios for energy and protein, we see a shift in the ratio of the ingredients and inclusion rates of these ingredients in the formulation. In the worst case, using NE values leads to similar feed costs, compared to ME calculations. “But feed cost savings per tonne of feed can be significant and using NE allows us to include more raw materials.”

Figure 2 – NE values provide a new hierarchy for feed ingredients.

Getting ready for the next big leap

Today’s challenges require precision feeding and there is demand in the market for more information on using NE values. Energy is a key (and most expensive) parameter in diet formulation, which makes the importance of having a net energy system even greater. Global poultry experts fully agree: NE is the most efficient system for addressing the nutritional value of feedstuffs as well as expressing the animal requirements. There is simply nothing to lose, one can only gain. “The information for NE application in poultry diets has been scarce, but more information is now becoming available, and we are learning how it works in practice. At the same time, we also applaud wider adoption of the NE system for pigs in regions such as Brazil, North America and Asia. NE is simply the most appropriate system, and the appropriate time to adopt it is now,” Pierre-André Geraert concluded.