New approaches to boosting the use of circular feed ingredients

Upcycling and evaluating ingredients with the new model SNAPIG are both valuable approaches that will help to boost the use of circular ingredients in animal diets.

Circular feed ingredients are a boon for society and the environment in that local food waste is converted into animal protein, while the use of virgin feed ingredients from crop sources is reduced.

But as Dr Alfons Jansman, senior scientist of animal nutrition at Wageningen University in the Netherlands, recently explained at the Animal Nutrition Conference of Canada, integrating these ingredients is not straightforward. ‘Upcycling’ – using intermediate organisms to make high-quality feed from raw food waste is one strategy, as is the use of a new software model called SNAPIG.

Circular feed basics

Generally, circular ingredients of plant origin (for example, fruit and vegetable processing by-products such as peeling and stalks) contain more fibre than conventional feed ingredients, making digestibility a problem. However, processing methods are being refined to address this. “To improve nutrient digestibility of dry and moist by-products and circular ingredients, we could think of fine grinding or related ‘mechanical’ methods, fermentation and for example, processing via enzyme treatment,” says Jansman, “before inclusion in the diets or via the use of combinations of targeted in-feed enzymes.” He notes that in pigs, it’s likely that inclusion of more by-products of plant origin in the diet will induce fermentation in the hindgut. The resulting short chain fatty acids will provide a larger part of the pig’s energy requirements relative to starch/sugars and fat. However, he says there are questions on “both the voluntary intake and maximum fermentation capacity of pigs in the hindgut when feeding more circular diets.”

Case-by-case approach

To boost the nutritional value of food processing by-products in feed, a strategy of specificity is needed, says Jansman. “The nature and composition of by-products is very heterogenic,” he says. “Specific approaches are required and need to be developed per ingredient. Also, developing of new methods requires collaboration between research institutions and the private sector, including producers of by-products, the equipment and technology sector, and the feed additive and feed industry.”

Jansman also notes that the industry could look at feeding more circular ingredients within a strategy of diets that are less nutrient-dense – accepting in turn that livestock productivity will tend to be somewhat lower. Furthermore, in a paper published last year, Jansman and his colleague Dr Paul Bikker noted that, when using circular diets, the use of feed conversion ratio as criterion of nutrient efficiency may become less relevant, while other criteria to assess the net contribution of feed ingredients to the human production food system are required.

As an example, let’s look at nitrogen and phosphorus excretion at the individual animal and farm levels with circular diets, which is expected to be higher due to a higher content of these minerals in the circular ingredients. Digestibility is also lower. But even as increased N and P excretion reduces the use efficiency of these minerals in an animal production sense, Jansman and Bikker explains that an increase in N and P excretion in circular feeding systems might be acceptable or even beneficial because of the value of the manure as fertiliser. So, while N and P efficiency is presently used as a criterium of farming sustainability, that perhaps needs more examination.

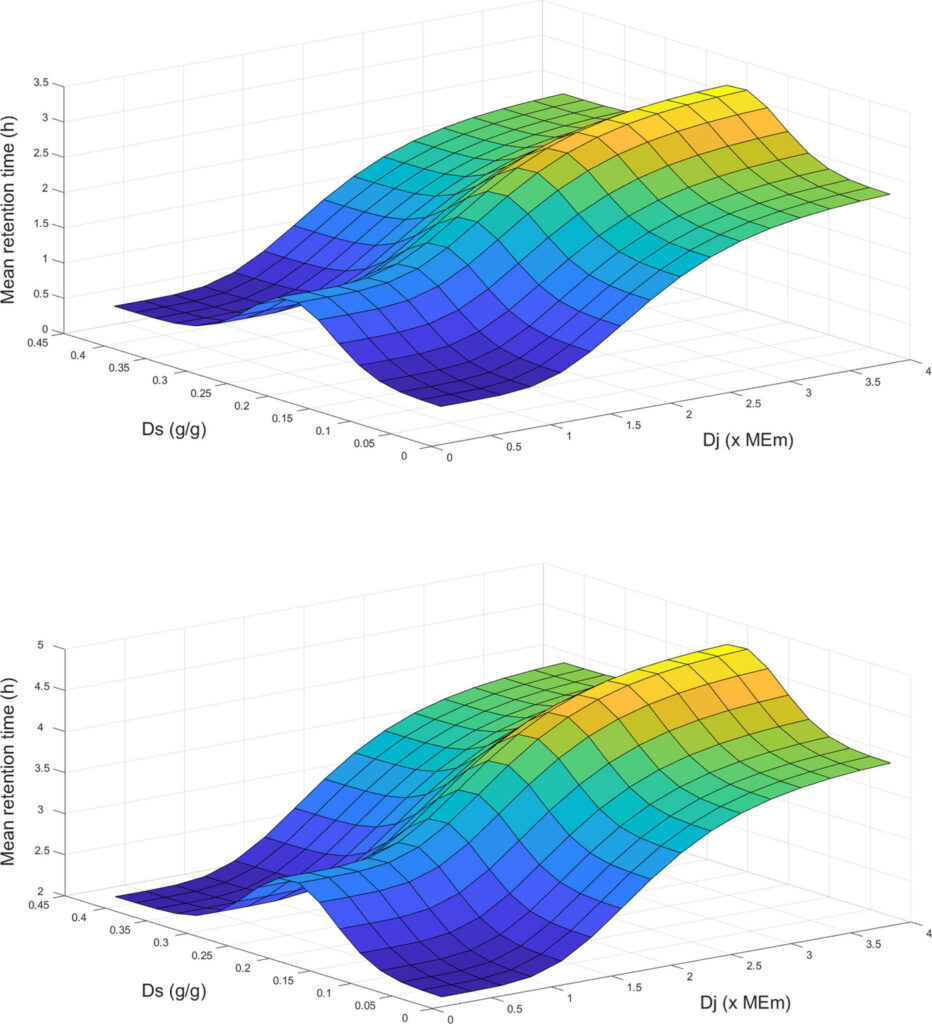

A visual representation of the SNAPIG model:

SNAPIG

To help address the variability generally present in circular by-product feed ingredients and to help evaluate them, Jansman and other colleagues have recently developed a model called SNAPIG (Simulating Nutrient digestion and Absorption kinetics in PIGs). This model aims to help users predict the rate and extent of nutrient absorption from diets varying in ingredient composition and physicochemical properties.

The team adds that “already useful as a research tool, SNAPIG can be coupled with a post-absorptive metabolism model to predict the effects of dietary and feeding-strategies on pigs’ growth response.”

Solving bottlenecks

According to FEFEC (the European Feed Manufacturers’ Federation), there are “current bottlenecks in the EU regulatory framework that restrict circularity in EU food systems through animal nutrition.” A critical review of this framework is needed, says FEFAC, to enable “further optimisation of the potential of the circular economy in the forthcoming EU Sustainable Food Systems Framework.”

Waste from catering sector: Untapped source

Concerning these bottlenecks, Jansman points to food wastes from cafeterias, restaurants and the catering sector. These represent substantial volumes and, due to their high nutritional value, they are well suited to pig diets. “However, their use is currently not allowed because of safety concerns,” Jansman explains. Specifically, because of their high moisture content, these food wastes easily spoil during collection, transportation and storage. Jansman also notes that these materials might also contain ingredients of animal origin which are not legally allowed in feed.

Upcycling

To solve this, FEFAC and others promote ‘upcycling’ – that is, first feeding these wastes quickly to intermediary organisms such as insects and algae, then using that as safe and highly-nutritious feed components. FEFAC reports that there are numerous research projects investigating the potential of using food wastes (as well as anaerobic digestate, livestock manure or municipal and industrial waste) as a substrate for the production of algal biomass for animal feed.

Jansman agrees that the upcycling of biomass into feed ingredients “could be an interesting route to convert more low-quality biomasses into more value ones, and finally bring new ingredients to the both the food and animal feed sector.” However, he points to the need to research not just the processes themselves but also how to scale up and increase overall economic viability.

Algae’s potential

Indeed, as Dr Ioannis Tzovenis notes, “with algae the issue is always the price.” Tzovenis is co-chair of the European Algae Biomass Association working group Algae for Aquafeed and founder of the company MicroPhykos in Greece.

At the same time, the quality of algae nutrition as a feed is well established. It has high levels of protein, vitamins, antioxidants etc., as well as immune stimulation, prebiotic, probiotic, antimicrobial, antitumour, etc. effects. Tzovenis and his team have run tests with Spirulina algae in feed for chickens, ruminants, freshwater fish and marine fish with good to excellent results. However, even the lowest-quality of Spirulina costs €7-10 Eur/kg compared to the highest-quality/highest-protein ats about €2/kg. The cost of feed from marine phytoplankton such as Nannochloropsis is much, much higher at present.

Costs aside, Tzovenis adds that currently in the EU, growing algae using manure is permitted but the “legislation is very strict.” It is not allowed in some countries and in those countries where it is allowed, “it has to undergo heavy safety analysis that increases the cost a great deal.”

He explains that “it is allowed though, if the waste is not of animal origin, which is also promoted in EU regulation for sustainability and organic production.”

However, because the nitrogen content of plant-based waste is normally low, it must first be processed before it can be ‘fed’ to algae. This involves anaerobic digestion with protein sources (sunflower at about €300-400/tonne or soybean meal at about €550/tonne), says Tzovenis, “to produce a digestate with decent nitrogen content to fertilise algae cultures.”