New thermostable enzyme helps meet demands for safer feed

A new xylanase enzyme, developed by Danisco, has recently been authorised by the EU commission for use in poultry diets. This xylanase comes from a fungal production system (Trichoderma reesei) and has been modified to maintain high efficacy despite exposure to feed conditioning and pelleting temperatures of up to 90ºC.

Increasing pressure over feed safety concerns and Salmonella control has increased the need to use heat in pelleting poultry feed. However, this is rarely in favour of feed efficiency and bird performance since it will increase the viscosity of diets based on grains such as wheat, triticale and barley. The use of a heat-stable xylanase can reduce the negative effects of increased viscosity in poultry diets pelleted at 90ºC.

The effect of heat on feed efficiency

High processing temperatures can inactivate endogenous enzymes in the grains used in diets; potentially reduce levels of certain vitamins; and potentially reduce the availability of protein and starch. Furthermore, increasing the conditioning temperature above 80ºC increases the viscosity of the diet and, consequently, gut viscosity in the bird, which will negatively interfere with the digestion and absorption of nutrients and increase the incidence of sticky droppings (Table 1). Trials have shown that increasing the pellet conditioning temperature for poultry diets from 80ºC to 90ºC in ‘viscous’ grain-based diets resulted in a significant decrease in body weight gain by up to 7%, and gave a poorer feed conversion ratio (4.4%) in broilers.

Grains like wheat and barley contain significant amounts of non-starch polysaccharides (NSPs). Soluble arabinoxylans are the main NSPs in wheat which increase the viscosity of the digestive contents in the small intestine. The heating process during pelleting solubilises even more arabinoxylans, which further increases the viscosity. Apart from the direct physical effects of viscosity in the gut, increased viscosity has a number of indirect negative effects on the nutritive value of poultry diets. These effects include reduced rate of feed passage, increased water consumption, and changes in the gut microflora. A slower feed passage rate in the gut can also create an environment that allows pathogenic bacteria to multiply.

Xylanases increase feed efficiency

The arabinoxylan in wheat is a substrate for the enzyme xylanase, which will degrade arabinoxylans, and there is much data to show that the enzymatic digestion of NSPs in poultry diets will lead to reduced gut viscosity and increased performance in birds. The addition of xylanase increases the energy value of wheat-based diets. It is therefore particularly important when formulating diets using viscous grains such as wheat, triticale and rye that an exogenous xylanase is used to minimise the negative impact of viscosity on bird performance.

Enzymes, however, are made of protein and are therefore sensitive to excessive heat. Enzymes differ in their intrinsic resistance to heat inactivation. Once the optimum temperature for a specific enzyme has been reached, increasing the temperature further, particularly in conjunction with extended conditioning times, can cause denaturing of the enzyme structure and thus irreversible loss in activity. Any exogenous xylanase has to be stable enough under higher pelleting temperatures to maintain its activity and efficacy in the animal.

Designing heat-stable xylanases

There are two ways of making enzymes more heat-stable. One approach is to use a coating to protect the enzyme; the other is to manipulate enzymes into more thermostable variants by changing their amino acid structure. Both technologies have been found to significantly improve enzyme stability and have been successfully used to produce commercial products.

A good coating needs to protect the enzyme molecule through the feed manufacturing process, but also needs to release the product very quickly in the upper part of the gut to ensure that optimum efficacy is achieved. Achieving the correct balance poses a big challenge for enzyme manufacturers as in vitro studies have clearly shown differences between products in the speed at which they can release the active enzyme. Danisco has used a patented Thermo Protection Technology (TPT) to design a free-flowing, dust-free phytase granulate product (Phyzyme XP TPT) with a recovery rate of 96% after exposure to feed pelleting temperatures of up to 95ºC. Trials have proven a fast release of phytase activity from this coated product and bioefficacy equivalent to the uncoated product in mash diets.

The second technology, modifying an enzyme by changing its amino acid structure to improve thermostability, has been widely tested in recent years. This technique includes the substitution of surface amino acids in the enzyme with more hydrophobic amino acids, as well as an increase in the number of specific amino acids that are capable of forming cross-bonds within the enzyme molecule. It is this approach that Danisco has chosen for the development of the new xylanase.

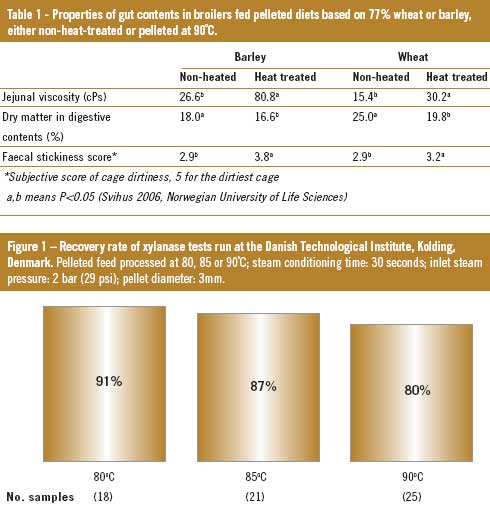

Tests run at the Danish Technological Institute at Kolding have shown that the recovery rate of this enzyme in pelleted feed samples was 80% at 90ºC (Figure 1). Danisco also provides a service to its customers based on a software programme (Avicheck), which determines the most cost-effective dose of this xylanase according to the viscosity of the grain used in the diet.