Novel feed pellet binders obtained from forest biomass

Feed binders are highly effective but also expensive. This is why feed manufacturers are seeking alternative feed-binding options. A study shows that galactoglucomannan derived from spruce trees could be a promising alternative.

The size of the feed binders market, with an annual growth rate of 3%, is estimated to reach over € 5 billion worldwide by 2025. Market growth may be the result of consumers appreciating the benefits provided by feed binders. Such additives can reduce dust in animal feed as well as operating costs, from feed manufacturing to consumption on the farm. These projected market dynamics are justified by the growth of the feed industry, feed raw material price volatility on global markets and increased popularity due to better nutrition and health benefits as a result of some feed binders.

Alternative options for feed binders

Binding agents currently used for feed production are highly effective; however, many binders are expensive. So feed manufacturers are seeking cost-effective, highly cohesive binding agents with low inclusion rates. Rapid changes in feed formulations, based on the need to reduce total costs and increase benefits are forcing feed manufacturers to seek alternative feed-binding options. Feed binders based on lignosulphonates represent the fastest growing segment in the feed binder market. Poultry feed manufacturers currently dominate in terms of the overall use of feed binders and growth in this market segment is expected to be strongest in the Asia and Pacific regions.

The purpose of feed pelleting is to agglomerate particles of feed into larger solid particles using pressure, moisture and heat. That is why pellets must have good physical quality in terms of hardness and durability to withstand the rigours of transportation within the feed plant as well as to farms. Demand for commercialising such feed additives is challenging as it needs to meet ethical, environmental and economic criteria.

Study galactoglucomannan as a feed binder

The Center for Feed Technology and the Norwegian University of Life Sciences have evaluated how galactoglucomannan (GGM) and its derivates − derived from the spruce tree (Picea abies) treated with steam explosion technology − may influence better binding ability between wheat-based particles under 1 mm in diameter. The materials used for this experiment were wheat flour, wheat starch and wheat protein concentrate. Experimental work was done using a single-die pellet press with total control of moisture, pelleting load and temperature during compaction. Control treatments were based on guar gum (B5) and LignoBond DD (B6). Tested inclusion rates for all binders were 0.25%, 0.5% and 1%. Binder 1 (B1) was based on 83% GGM, binder 2 (B2) on 98% GGM, while binder 3 (B3) had partially deacetylated GGM and binder 4 (B4) fully acetylated GGM.

Promising results

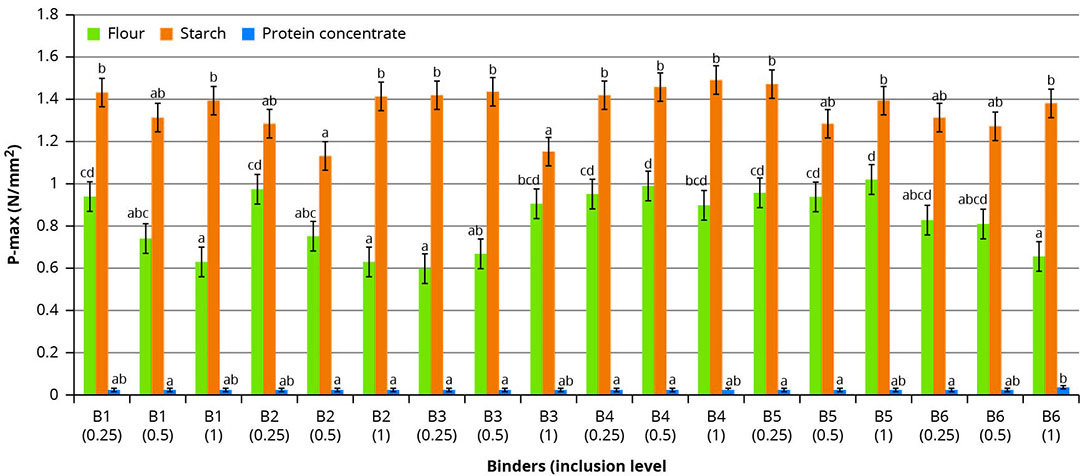

The experimental work with wheat flour shows that all novel binders can be successfully used in the pelleting process, with the conclusion that pressure at initial flow (p-max) decreased when the inclusion rates for binder 1 and 2 were increased. The acetylation process of the binding material increased the p-max, independently of its degree of acetylation. However, this increase was not significant for the control binders when used in wheat flour. For wheat protein concentrate and starch material no differences in p-max were observed by adding different binders. Lower p-max can result in less use of electrical energy during commercial pelleting.

The tensile strength of the wheat flour pellets was not influenced by different binding agents when compared to the control binders B5 to B6. Variables related to different binders and their inclusion rate in the wheat starch compacts were non-significant when compared to the control binders. However, the tensile strength between B1, B2, B3 and B4 was significantly different, with the lowest tensile strength for B2 (0.5%) and the highest for B1 (0.5%). The tensile strength of the pellets made of wheat protein concentrate was not significant when compared to guar gum and lignosulphonate. However, the tensile strength of the wheat protein pellets in B1 and B3 at level 0.5% were different (p<0.05) from B1 and B2 at the 0.25% level, and B6 at the levels 0.25% and 0.5%. The highest tensile strength was observed at B6, level 1.0% and the lowest was at B3 level, 0.5% (Figure 1).

Figure 1 – P-max of the diets containing wheat flour, starch and protein concentrate with different binders at different inclusion levels. Different letters indicate significant differences for bars of the same colour.

Effect on water activity

Different binders influenced overall water activity (aW) measurements. Significant aW differences (p<0.05) were observed at all inclusion levels between the control binders and B3 − for pellets based on wheat protein concentrate. The highest aW was observed at B2, 1.0%, while the lowest were B3 and B4 at 1.0%. The aW of the pellets made with wheat flour was affected by different binders and their inclusion levels. Control binder B6 had the strongest effect on reducing water activity, with no significant differences between addition levels. A clear tendency for changes in aW in the wheat starch pellets was not observed. For different binders a small change in aW was correlated with hardness, but only for the pellets based on wheat flour (Figure 2). For other wheat-based materials such a correlation was not observed.

Figure 2 – Correlation between tensile strength (N/mm) and water activity (aw) of wheat flour.

Novel feed binders can be used successfully

Novel feed binders obtained from forest biomass after steam explosion and based on different purities of galactoglucomannan and its level of acetylation can be used to bind feed particles, without reducing the hardness of the pellets based on wheat flour, wheat starch and wheat protein concentrate.