Proteases in broiler diets require careful selection

While the animal feed industry has successfully managed to procure commercial enzymes that enhance the efficiency with which broilers derive energy and phosphorus from their feed, it has not been so successful in the case of protein. Earlier attempts at using proteases in commercial conditions were, at best, inconsistent. This is perhaps not surprising, given that many of the first proteases to enter the feed market were developed for the detergent industry and only later adapted for use in feed.

A pure protein degrading enzyme would provide the feed producer with a valuable tool to consistently improve the amino acid digestibility of feed ingredients. This in turn offers a range of economically attractive benefits. Recently, Ronozyme ProAct (ProAct), a unique and pure protease, specifically selected for use in feed has been launched.

The main reason broiler producers as well as feed producers require a protease enzyme is profitability. Protein raw material prices have shown a sustained upward trend over the last few years. Despite abating a little in the last few months, the general consensus of independent observers is that prices will continue to increase in the future. This is the consequence of consumption exceeding supply on account of demand from emerging economies, and the impact of bio-fuel production on the composition of harvested areas across the world. A protease which can consistently improve the digestibility of amino acids in such materials, thus reducing their inclusion level in feed while maintaining current levels of animal performance, is therefore economically very attractive.

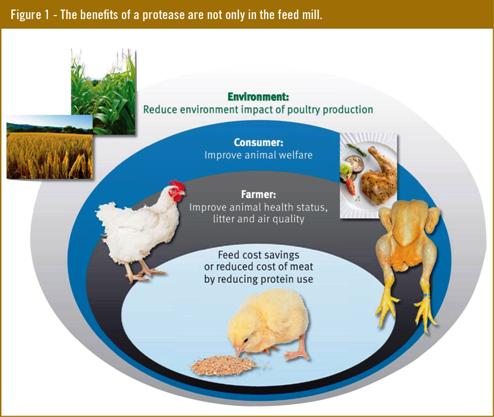

Direct cost savings at the feed mill, however, are by no means the only reason for considering a protease (Figure 1). When a suitably efficacious protease is used, it can be an important contributor to the continued economic viability, sustainability and consumer perception of the broiler industry.

Not all proteases are the same

For a protease to be successful in feed it should, like any other enzyme, be selected and developed with that specific use in mind. Unfortunately, many of the first proteases entering and in many cases still available for use in the feed industry were developed for other purposes. Typically, these products are the so-called subtilisin proteases: non-specific alkaline proteases initially derived from Bacillus subtillis and developed for the detergent industry, with characteristics which render them less effective in feed.

The recent development of ProAct, a unique protease specifically selected for application as a feed enzyme, has overcome many of these issues. Unlike most other commercially available proteases, it is not a subtilisin protease; it is produced from a genetically modified strain of Bacillus licheniformis. In the selection process, factors such as the ability to degrade many different feed proteins; the need to complement the endogenous protease enzymes; activity after exposure to the low pH conditions of the gizzard and proventriculus; and stability during feed processing were all taken into account.

pH stability

Probably one of the most important criteria for success of a protease in broilers is good stability under low pH conditions found in the bird’s stomach. Typically, the stability of subtilisin proteases is poor under conditions of low pH. The level of viable enzyme reaching the ileum is thus also limited. In contrast, with Bacillus licheniformis derived protease, stability at low pH is greatly improved, ensuring sufficient enzyme activity in the small intestine to give the desired hydrolytic effect.

For a protease to work successfully, it is essential that it should complement the endogenous enzymes. The bird’s stomach and small intestine already produce pepsin and pancreatic proteases, respectively. The exogenous protease must work in synergy with these enzymes to obtain the optimum benefit in all but the very young bird, where endogenous levels may be limiting.

Figure 2 shows the increase in protein solubility and the degree of hydrolysis of feed peptides in an in vitro monogastric digestion model. Different commercially available products containing protease activity were added on top of the endogenous enzymes. While all products tested increased protein solubility to some extent, only ProAct was able to increase the degree of hydrolysis of the peptides, suggesting that this enzyme, unlike others tested, can work in a complementary manner with the endogenous proteases. Given the poor stability of the protease in the other products when exposed to low pH, it is also highly probable that the effects seen on solubility were not the consequence of protease at all, but were due to the ‘de-caging’ of protein by other enzyme activities also present in these products.

Flexibility of use

For a protease to be commercially useful it must be possible to use it flexibly in a diverse range of diet types. The ability to improve the digestibility of protein from as wide a range of feed ingredients as possible is therefore important. Figure 2 shows the additional protein digestibility achieved in an in vitro digestion model for a range of commonly used feed ingredients when ProAct was added on top of the endogenous digestive enzymes.

This clearly shows that the protease has the potential to improve digestibility of protein in a wide range of ingredient sources in vitro. Such improvements should however not just be obtainable in vitro but also in vivo. In vivo, both ileal and faecal amino acid digestibility studies have confirmed the significant improvements in digestibility for a wide range of different raw materials when ProAct is added. Some examples are shown in Figure 3.

Processing stability

As the conditioning time and temperature during the production of pelleted broiler feeds becomes ever higher and longer to ensure compliance with increasingly stringent food and feed safety requirements, stability of feed enzymes under more extreme conditions is increasingly essential. To this end, for a protease to be successful, thermo-stability is a must. A trial carried out at the Technological Institute, Kolding, Denmark showed significant differences in stability between different commercially available proteases, when exposed to different conditioning temperatures (70―95oC) for varying duration (30―120 seconds). ProAct was consistently more stable at each of the conditioning times and temperatures tested, achieving 100% recovery when conditioned at 75oC for 120 seconds, and over 90% recovery at 95oc for 120 seconds, demonstrating its superior stability even under more demanding conditions.

Economic benefits

The benefits of including a protease such as ProAct in broiler diets are confirmed in numerous published reports. Such research shows that this protease can improve the protein digestibility of a wide range of natural ingredients by 3―8%. Such improvements translate into cost savings of €2―6 per tonne of feed and are achieved without any compromise on animal performance.

For example, a European field trial compared performance of broilers fed an industry standard control diet with maize, wheat, soya and rapeseed meal as the core ingredients to a diet formulated assuming the digestible amino acid levels of the natural ingredients were on average 4% higher when the diet was supplemented with 200g of ProAct. Savings averaged €4.00 per tonne of feed, while performance at 45 days was at least maintained. A similar study compared an industry standard control wheat, soya and rapeseed meal based diet containing a xylanase enzyme and phytase to a diet of the same specification but formulated assuming the digestibility of the amino acids in the natural ingredients were 6% higher. When 200g/t of ProAct was added to this feed performance was even improved relative to the control.

Profitability, environment and welfare

In conclusion, the use of a protease not only has the potential to increase the profitability of a broiler enterprise, but can also have a positive impact on the environment and help improve litter quality and associated incidence of economically important welfare parameters. Choosing a protease which has been selected, and developed, with the right characteristics for use in feed production is, however, key if these benefits are to be realized.

Author:

Dr Adam Smith, DSM Nutritional Products, UK

Dr Adam Smith, DSM Nutritional Products, UK