Sweet haylage, an innovation in feeding dairy cattle

Green forage is the most preferred feed for dairy cows by farmers. However in many countries this is not always available and farmers often have to feed cows what is left from processing fruits or vegetables. These fibres contain relatively little energy and protein, but processing them following a new concept might change this.

Fibre is the slowly digested or indigestible material in feeds. Typically, fibre measures the plant cell wall: the structural portions of the plant that give it support. Fibre components of the cell wall, including cellulose, hemicelluloses, and lignin, as well as pectin, are digested only by the process of microbial fermentation. In the rumen of dairy cows a thriving population of bacteria, protozoa, and fungi produce enzymes that break the very complex components of the cell wall into smaller molecules such as glucose. Nutritionally, fibre is the portion of feed that: 1) limits digestion; 2) requires chewing for particle size reduction; and 3) occupies space in the rumen because of bulkiness, thus limiting intake.

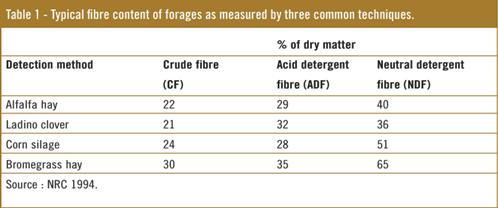

The three methods used for measuring fibre in feeds include:

- Crude Fibre (CF),

- Acid Detergent Fibre (ADF),

- Neutral Detergent Fibre (NDF).

Each of these measurements is found on various feed tags and forage analysis reports. Although they all measure fibre, each method gives different fibre values for one feedstuff (Table 1). Much confusion can be avoided by realising exactly which chemical component of the plant cell wall is being measured by each method. Several methods to treat fibre to increase digestibility are available. The methods use chemicals such as sodium hydroxide, ammonia and calcium oxide. At present time the only method recommended for practical application involves ammoniation either using gaseous ammonia or through wet ensiling of the material with urea. The effect of this treatment is to increase digestibility (often by 5–10% units, to approximately 1% of the dry matter) and to increase acceptability and voluntary intake of the treated fibre/straw as compared to untreated straw (usually by 25–50%) when this is made available on a free choice basis.To increase the nitrogen content of the straw ammonia as gas or generated from urea (by bacterial and/or plant ureases in the ensiling process) hydrolyses the chemical/physical bonds between lignin and the cellulose and hemicelluloses in the plant cell walls. The hydrolysis of these bonds makes the cellulose and hemicelluloses more accessible to microorganisms in the rumen and increases total fermentation and usually the rate of fermentation. Some chemical hydrolysis of hemicelluloses also takes place resulting in an increase in the portion of soluble.

Technology solution

In Kerala, India the dairy farmers are depending on paddy straw and poor quality compounded feed to produce milk. It is noticed that the milk is produced at the rate of 1.5kg feed for 1 litre milk. The above phenomenon increases the milk production cost to the highest in the world. Recently it was declared as Rs 24 (€0.35) for 1 litre milk produced. Since all cattle feed raw materials are imported the feed price would go up beyond control. Therefore, it is necessary to develop a substitute feed with locally available feed recourses in Kerala.

In reality many comment that no feed is available in Kerala except waste vegetable fibre like banana stem and leaves, coconut leaves, African payal (an invasive weed), tree leaves and waste grasses. In order to convert those items to good quality feed the only recourse is technology. Synery Group of Companies, UAE has successfully innovated a technology and plant to manufacture ‘sweet haylage’ as a substitute for green forage. The above feed is more digestible, energy rich and palatable. Since the waste fibres are used the cost of the new feed will be indeed half of other poor quality compounded feeds.

Sweet haylage

Silage and haylage making are processes involved to preserve the green forages. Silage making is done by pressing chopped green forage into deep silo pits and covering it with soil to preserve it by the production of propionic acid. The treated silage is taken out for feeding during winter days when green forages are scarce. The ensiling treatment causes loss of sugar and starch and protein by fermentation. However fibre remains available to the cow. The production of propionic acid lowers the pH below 5.

Haylage making is done by withering the green forage by drying under the sun to remove moisture to 50%. This semi dried forage is chopped and packed with high pressure. The air tight packing stops the loss of nutrients to some extent.

Utilising the advantages of the silage and haylage processes, sweet haylage was developed to process waste vegetable fibre. Moreover there is no effective treatment available for crop residues. Straw treatment with various agents like ammonia, urea, micro flora etc were tried but were never successful in the field. The feasible industrial model was not developed for such a treatment.

Later urea-molasses multinutrient blocks (UMMB) were developed to manipulate rumen fermentation. Commercial plants were developed for the production of UMMB in India. However owing to various reasons it was found less acceptable particularly because of higher cost for molasses.

In sweet haylage technology all those technologies were combined to make the vegetable fibre more digestible and energy rich and palatable. These fibres are chopped to 15mm particle size and mixed with additives like nitrogen, phosphorous, sulphur, sugar, probiotics and enzymes and pressed at 4,500 psi (310 bars) pressure to form hard blocks and packed air tight to remove oxygen. The packed block will have carbon dioxide to encourage the growth of fibre degrading bacteria. The packed feed is left for 20 days to complete the reaction so that microbial protein will be produced, fibre will be degraded, energy content will be increased and the feed will be highly palatable. Depending on the formulations the feed will have 8-10% protein and 10-11 MJ/kg metabolisable energy. If the pack is left intact the feed will remain for long time.

Processing plant

To manufacture the blocks the processing plant is equipped with the following parts: juice remover, spindle remover, chopper, digester for additives, mixer/sprayer, hydraulic press and shrink packing. The machinery will remove the excess moisture in the vegetable fibres and reduce the particles to 15mm size. A mixing technology is developed to coat the liquid ingredients on the vegetable fibre evenly for bacterial and chemical treatment. Processed fodder is compressed to dense blocks of 5kg and packed airtight to prevent oxidation of nutrients. The sweet haylage is ready to use after 28 days from packing date, with a shelf life of two years. The layout of the plant is shown in Figure 1.

In summary

The above technology would bring in impressive changes in the feed scenario by treating the vegetable fibre to form a good quality feed for dairy cows. Since the plant is small and compact it could be installed in local areas where fibre is plenty. Also the electrical load is low therefore it could be available in villages. In countries where the feed resources are dear and scarce, development of sweet haylage technology would convert the waste fibre to energy rich fodder feed for ruminant animals for milk and meat production.

More information on the technology can be obtained from the author at pgkjohn@gmail.com