The effect of using essential oils and spice extracts on crude protein levels

The feed costs of livestock production remain under pressure. Broiler production has been particularly hardly hit, as it remains the cheapest and most popular source of meat in the world. The efficient use of proteins is therefore at the heart of the matter.

Lowering protein incorporation levels is an economic possibility, but it is also desirable for health and environmental reasons. While some authors showed that lowering protein can contribute to animal health problems, others observed that, on the contrary, a well-balanced low-protein diet is better for health. On the other hand, it is important to ensure that production performance is maintained.

Plant extracts

In the past, plant extracts have played a key role in maintaining production performance after the withdrawal of AGP in Europe in 2006. For some authors, the results seemed inconsistent, with a deterioration in the Feed Conversion Ratio (FCR). Other authors observed an improvement in results, including for the FCR. Among the numerous solutions that have been launched back then in 2006 to replace AGPs, only a few products have proven their efficacy and remained on the market since then. Today, to meet the challenge of improving feed efficiency, a large number of different solutions are being launched, but they have yet to prove their consistency and effectiveness.

So, what would the criteria be for an ideal plant extract to be effective in reducing animal protein? We need a solution that delivers both consistent results and acceptable costs.

Different types of plant extract

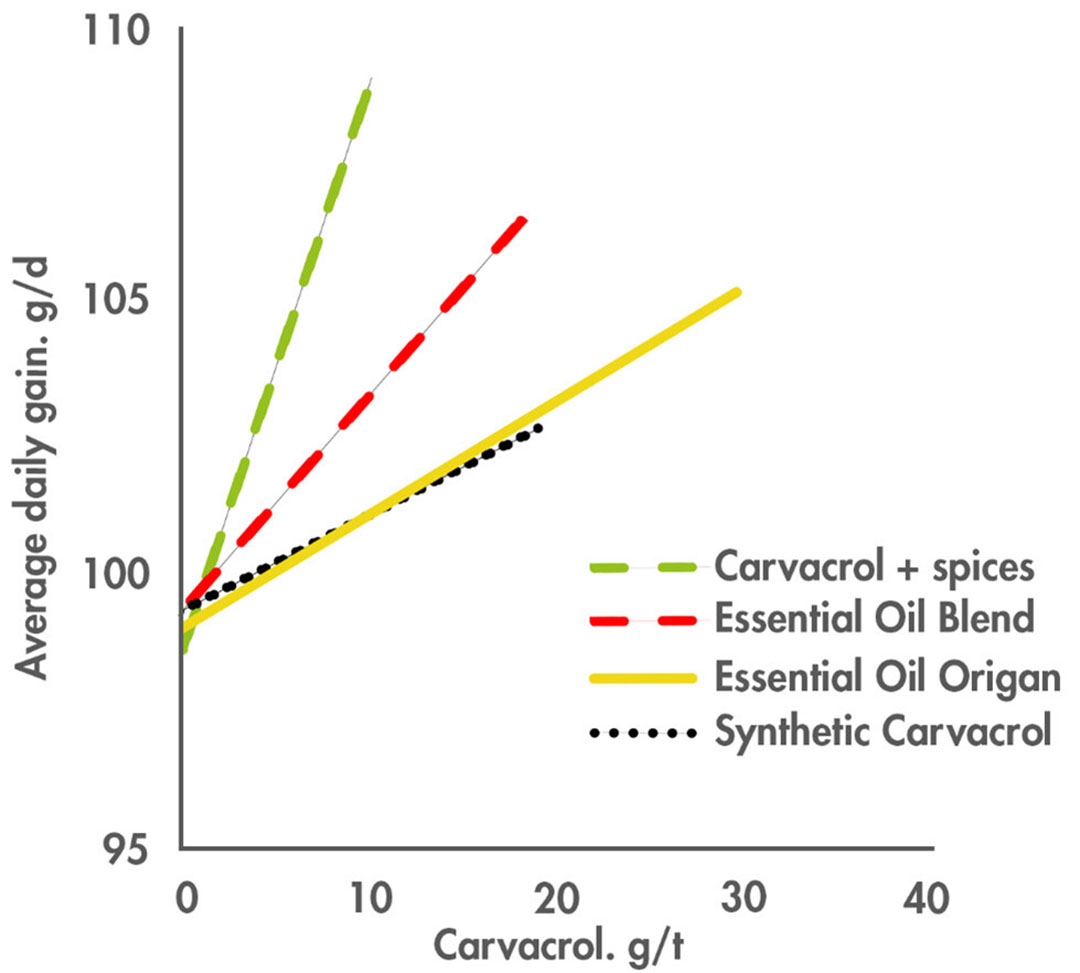

There are several types of plant extract. Starting with simple grounded plant parts. These are cheap, but their concentration of active ingredients is highly variable, so they are not recommended. At the other end of the spectrum are synthetic molecules. By their very nature, these molecules are standardised, the cost of treatment is acceptable. However, their effectiveness in all situations may be limited due to their lack of synergy with other components. While natural molecules offer great synergies when used properly. The best compromise is certainly the use of a blend of several essential oils chosen for their antioxidant, anti-inflammatory and antibacterial properties. But here again, standardised sourcing is essential. The content of active ingredients such as carvacrol or thymol in a thyme essential oil, for example, can vary from 60% to less than 1%. It is therefore necessary to master the chemotype of the essential oil. A blend of several oils also helps to limit fluctuations from one year to the next, so that the animals always receive the right level of active ingredients. Adding a mixture of oleoresins of spices such as capsicum, ginger and others greatly potentiates the effect of essential oils (Létourneau Montminy, 2022 Figure 1). These products remain fairly standardised, have a competitive treatment cost and, because of their complexity, the best regular response.

Figure 1- Impact of the complexity of the blend on performance.

Powerful active ingredients

The level of incorporation of these powerful active ingredients into the feed is low (in ppm terms). Even the best blend of essential oil and spice will not improve the consistency of the results if it is not administered evenly throughout the feed. These additives must be applied to a carrier that has a high affinity with flour (galenic technology). Particles whose appearance (shape) is close to that of the feed particles are to be preferred. Spherical particles should be avoided, as it is difficult to optimise their mixing homogeneity.

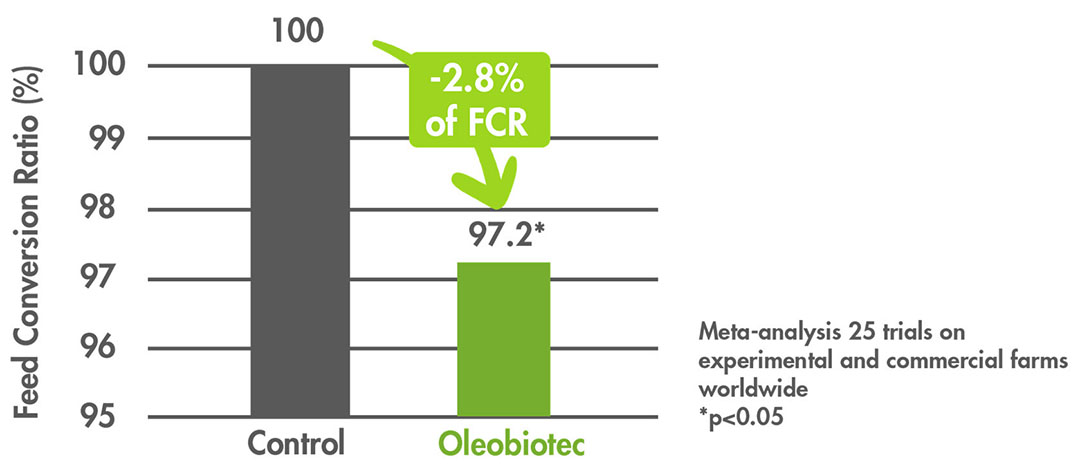

A product (Oleobiotec Poultry, Laboratoires Phodé) that respects these criteria: a blend of standardised essential oils, spices as a booster and a galenic support adapted to the broiler feed give you satisfaction. In a meta-analysis of results observed in experimental and field conditions around the world, Létourneau Montminy found a 2.8% reduction in FCR with such a product (Figure 2).

Figure 2- effect of a blend of essential oils and oleoresins on FCR (Oleobiotec Poultry, Meta-analysis).

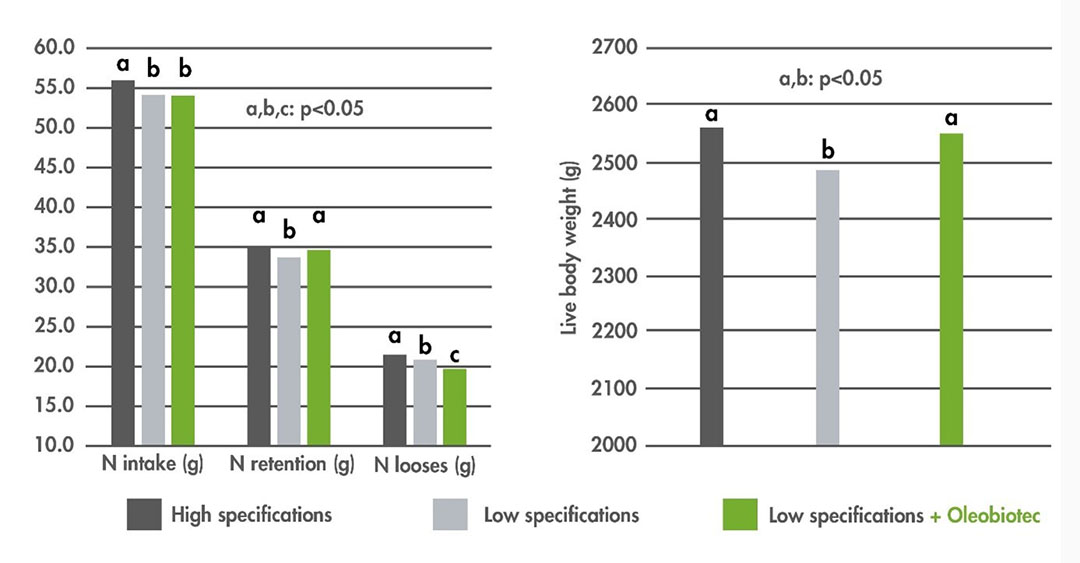

It also has maintained the performance of chickens fed a diet formulated with 2.5% less energy, crude protein, and amino acids. An improvement in nitrogen utilisation was also demonstrated (Gabarrou, 2018, Figure 3).

Figure 3 – Effect of a blend of essential oils and oleoresins (Oleobiotec Poultry) on nitrogen retention and live body weight in broilers fed a a diet reduced in energy, crude protein, and amino acids by 2.5%.

As was the case in 2006 when PFAs were withdrawn, plant extracts can now meet the challenge of lower protein levels in poultry feed. Provided we are familiar with the synergies between these essential oils and oleoresins and know how to apply them to carriers that will support the homogeneous incorporation of the mixture into the feed.

References are available on request.