Uncovering the hidden costs of feed efficiency in livestock production

Jose Ramirez, technical director at Anitox, offers his insights into the key factors that influence feed efficiency and reveals some hidden costs that can emerge and how producers can optimise feed quality to support animal health and operational profitability and sustainability.

It goes without saying that feed efficiency is key to animal performance and therefore producer profitability and sustainability. Producers optimise animal genetics, formulate to specific animal requirements and incorporate various additives to optimise animal production. Taking steps to improve feed efficiency is critical to these efforts. However, pursuing feed efficiency improvements can present unforeseen challenges that producers must carefully navigate.

Primary factors influencing feed efficiency and their differences across poultry and swine

Ramirez: “There are many factors that are well recognised and understood to improve livestock feed efficiency. Genetics, for example, uses selective breeding to enhance animals’ ability to convert feed into growth more effectively. This, however, makes nutrition and feed management equally important, requiring a tailored approach based on species and age. And we must not forget environmental factors like housing and temperature and of course health.”

These core factors – genetics, nutrition, environment and health – are consistent across poultry and swine, with some specific challenges that vary between species due to their distinct biological needs. When these factors are managed and managed well, producers are well on their way to achieving improved performance.

“But there is another major factor that is too often overlooked: feed management. Feed management also requires a tailored approach based on species, age, and environmental factors. Proper feed formulation and delivery, such as mash or pellets, ensures maximum utilization,” says Ramirez.

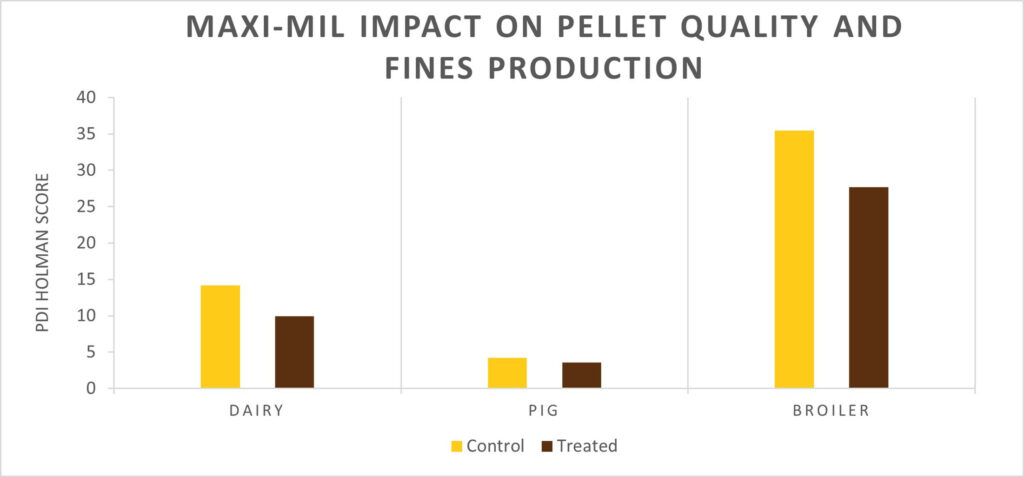

In some cases, the role pellet quality plays in improving feed efficiency is underappreciated. There is no doubt that pelleting optimises moisture levels and improves feed form and nutrient distribution in the feed, leading to improved feed conversion ratios (FCR).

“Improved feed conversion ratios is supported by robust evidence. Research published in 2021 by Aviagen nutritionist Marcus Kenny demonstrated that good feed physical quality, compared to poor physical quality containing a high percentage of fines, promotes performance and processing yield in turkeys. Other research, such as Glover et al., 2015, found that a 20% improvement in whole pellets at the feeder led to a 3-point improvement in FCR in broilers. That’s huge,” explains Ramirez.

“The literature reports a similar trend in swine. As pellet fines decrease, we see a clear improvement in feed efficiency. Schell 1998, a study in grower pigs showed that reducing fines from 37% to 3% improved feed efficiency from 2.10 to 2.01. Another huge improvement. Similarly, Stark 1994 published a study in finishing pigs, reducing fines from 60% to 0% improved feed conversion from 2.82 to 2.65.”

It is unlikely that any producer would overlook the potential for even a slight improvement in their feed conversion ratio. However, feed quality frequently fails to receive the attention it merits, possibly due to focusing more on the nutrition and formulation aspect of the feed and less on the execution of delivering it in the correct form.

Hidden costs producers might overlook when focusing solely on feed efficiency

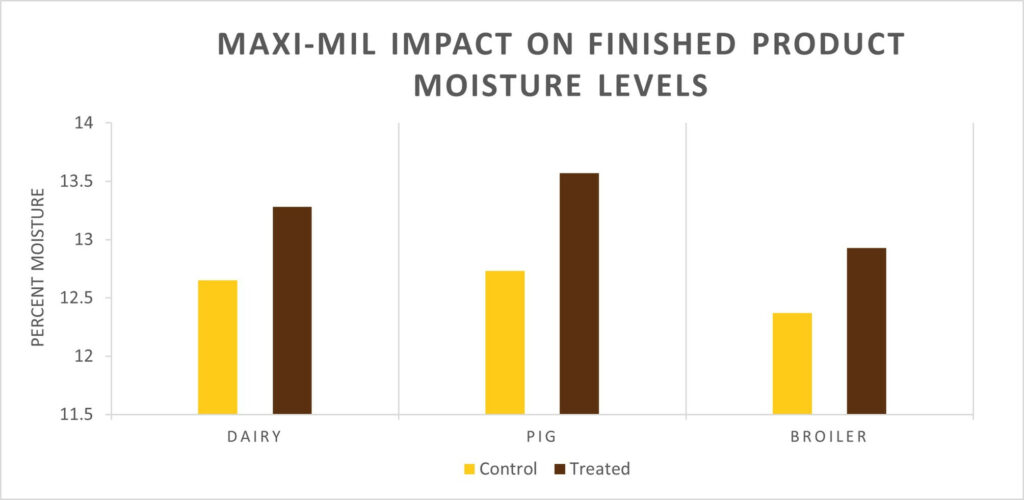

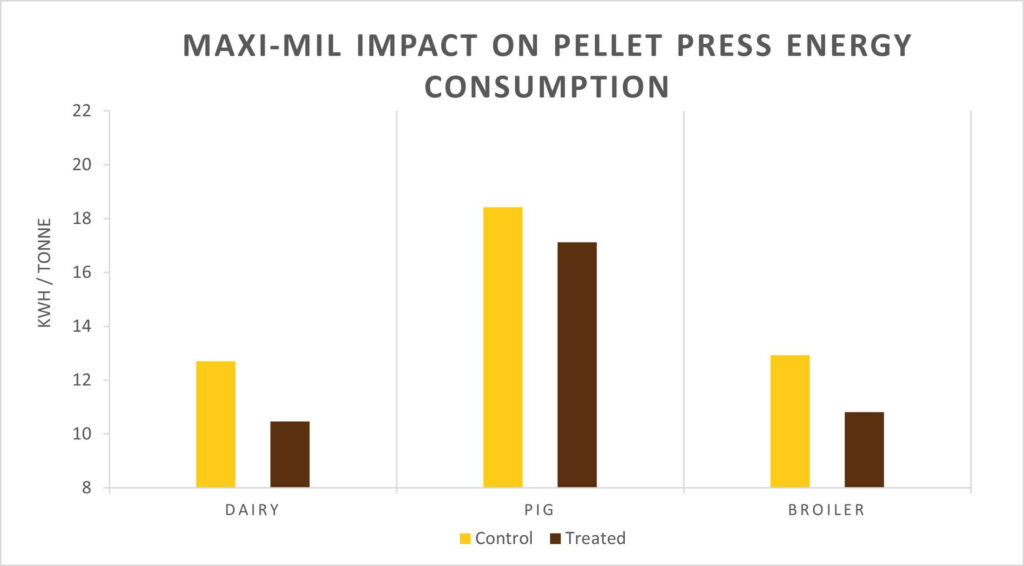

Producers can access the clear benefits of improved feed efficiency by improving pellet quality and optimising feed production. Some strategies that enhance pellet quality may even improve mill throughput and energy consumption. Maxi-Mil helps mill managers balance feed gelatinisation, moisture control and pellet durability, enhancing overall feed production efficiency. Proper moisture management is key to preventing contamination, improving microbial quality, and ensuring efficient heat distribution, which enhances starch gelatinization and nutrient digestibility.

Trials conducted by the International Research Institute of Feed Technology with Maxi-Mil show that 1% inclusion improves conditioning rates, pellet quality, moisture retention and energy efficiency, resulting in longer shelf-life and higher feed performance.

While it is essential to prioritise well-established factors such as genetics, nutrition, environment, and health, as they undeniably impact efficiency across species, it is equally important not to overlook feed efficiency and pellet quality. The potential benefits of addressing these aspects are substantial, and failure to do so may result in significant negative consequences.

Poor pellet durability and excessive fines can lead to wastage and nutrient segregation, diminishing overall feed value. Not all strategies and solutions used to increase throughput or manage moisture contribute positively to the physical form of the feed. Implementing solutions such as Maxi-Mil allows mill managers to effectively tackle moisture management, process losses and throughput challenges while enabling the production of higher-quality, more efficient feed.

Producers seeking to unlock the full potential of feed efficiency without compromising animal health or profitability should visit www.anitox.com.