Achieving operational harmony in extruding

When considering a state of operation that maximises efficiencies and throughput, one must consider the tools they use and how they are implemented. In terms of extrusion processing and screw wear, this refers to the proper extruder components and proper application of basic extrusion principles.

The equipment/process appears to be running well, the production schedule is tight, and the thoughts go to “it’ll be OK to delay addressing those pesky maintenance schedules and wear part rotations for a bit longer”. Well, the obvious reason to address the maintenance schedules is that soon the machine will stop ‘running well’, and in some cases not run at all.

Of all the processing issues that our service department deals with that begin with ‘…we have been running this product for 3 months without out a problem and then all of a sudden…’, 95% of the time the leading factor was either the raw materials or typical maintenance/wear issues. The process of creating pet food requires mechanical energy. Product specifications, cell structure, pellet durability, and raw materials will all dictate the amount of mechanical energy input required to produce a specific product. In due course, this mechanical energy input comes at a cost; equipment wear. In the extrusion process there are three primary types of wear: chemical, galling, and normal processing (abrasion) wear.

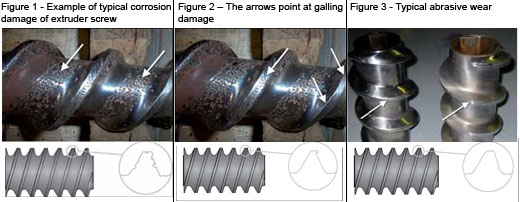

Chemical or corrosion wear (Figure 1) is seen as rough-sided indentions on the surface of screws and liners. This wear may be caused by any of the following:

- Metal not compatible with the pH of the extrudate;

- Salt;

- Cavitation in a low pressure area of the barrel.

Galling wear (also known as forging) can be seen as rough surfaces on the outside diameter of the screw. The screw flights may have a welded, gouged, or even a torn appearance with a sharp edge on the back (lagging) side of the flight. This is commonly caused by a severe mis-alignment of the shaft in relation to the barrel, or by a non-uniform flow characteristic of the feed in the barrel. Figure 2 illustrates typical galling damage.

Abrasion wear (Figure 3) will be seen as a rounded, smooth radius on the front (leading) side of the flight at the outside diameter. This is caused by leakage flow of the extrudate across the outside diameter of the screw. This is normal, and expected, wear of the extruder screw.

Predicting excessive wear

To a degree, the wear characteristic of a specific extruder configuration with that of a given formulation can be predictable, and does render ‘indicators’ that will alert the process of a impending ‘excessive wear’ situation. The following is a list of these possible indicators:

Prolonged extruder start-ups

Excessive wear on the components will hinder the process from obtaining a proper steady-state of processing. Un-worn components will generate the energy and heat in a shorter time-frame than worn components. This in-turn will also generate more waste which increases cost of production.

Blocked steam injectors

When the product ‘plug’ in the barrel extends back into the steam injection zone, the steam pressure is typically not high enough to over-come the product pressure, in turn causing the steam injection to fall. This event can easily become cyclic, rendering an unstable process that generates excessive amounts of wasted product.

Capacity losses

Because the components are worn, they will not have an efficient ability to transport/convey the product through the barrel. This will cause the over-all product rate (kg/hr) to be reduced, and possibly cause the product to ‘back-up’ into the inlet.

The following are other, more product specific, indications of excessive component wear:

- higher extruder motor amperages

- product surging

- unpredictable extruder shaft ‘lock-ups’ with High SME products

- loss of density control for specific products

- un-even die pressure producing varying pellet sizes

- loss of starch gelatinisation and product expansion.

Operational harmony

First let’s address the component aspect of operational harmony. In most cases of galling wear and catastrophic failures, it is determined that the process was utilising third-party or after-market screw/barrel components and often times these are no more than the Original Equipment Manufactured (OEM) part “rebuilt” by a third party. The decision to use these third party components is usually justified as a cost reduction measure.Photo 1shows a screw that was rebuilt by an aftermarket part provider. It should be noted that this was a used OEM part that was rebuilt using multi-pass welding techniques to build up worn screw flights. The end result, welding materials cracked away from the original screw material and heat generated from the welding process changed the hardness of the screw unit resulting in cracks throughout the unit. Photo 2and3illustrate the amount of damage resulting from again screws that were rebuilt by an aftermarket part provider. In this case the mating surfaces between the screw sets were not machined flush or parallel after the rebuilding process causing misalignment resulting in major damage to not only the screw but also the barrel liner.

The above has focused primarily on screw and barrel components. However, the same problems are incurred when purchasing copied dies, knives, etc. Many of these aftermarket providers are solely “copiers” that just duplicate close to original material sizing and do not take into account, metallurgy, pitches, angels, land lengths, etc. They have no engineering or technical experience, specifically in extrusion. To the consumer it “looks the same” but it definitely doesn’t perform the same and often times causes more production loss, even increasing the clients chances of catastrophic equipment failure.It is important to be mindful that the OEM part has been engineered and manufactured to insure your equipment operates within specified tolerances, minimising wear and most importantly that it functions at optimum capacity and energy efficiencies. Responsible and responsive OEM, design replacement parts such as screws, barrel liners, shafts, wear plates, etc. based on the customer’s process, take into consideration items that cause part wear such as raw ingredients, mechanical forces, etc. For example, Extru-Tech’s design of parts includes achieving very specific tolerances and component metallurgy to minimise downtime causing faults. These tolerances and metallurgy considerations are often not even considered by the “third-party” vendors.