Dinnissen presents new range of hammer mills at EuroTier

Dinnissen Process Technology has developed a new and extremely wide range of hammer mills. They will be presented at the upcoming EuroTier show 11-14 November.

Hammermills are particularly suited for grinding soft to medium-hard products such as grains, herbs, spices, protein-rich ingredients, nutrients, premixes, and minerals. Dinnissen’s new range of multitasking hammer mills enables the user to screen output particles ranging in size from 3 mm down to 150 microns. Two rather striking members of the new product range are the small Easy-to-Clean DINNOX Mill and the Dinnissen D-Topline Hamer Hammer mill with automatic screen changer.

The Easy-to-Clean DINNOX Mill is a very compact hammer mill with a minimum capacity of 30 kg per hour. The small Easy-to-Clean DINNOX Mill is fitted with exchangeable grinding rotors, providing it with a variety of breaking, cutting, and grinding functionalities, as well as exchangeable screening panels and adjustable RPMs. This allows the user to easily and quickly switch between an almost endless variety of grinding and screening applications, depending upon the specific ingredients process and the desired end result.

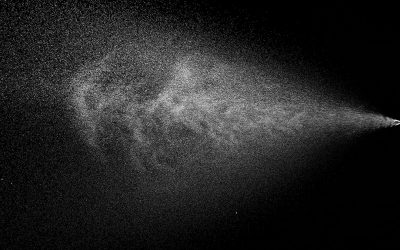

The new D-Topline Hamex Hammer mill (pictured) with automatic screen changer can handle grinding capacities of up to 45,000 kg per hour, and the screen changer has space for 4 to 6 different sets of screening panels. The mechatronic screen changing system automatically selects and places the appropriate set of screening panels in the hammer mill. After the production process has been completed, it also removes and stores the screening panels in less than 40 seconds. This makes it possible to change screens extremely quickly and greatly reduces downtime. The D-Topline Hamex Hammer mill features a new and ingenious design which greatly increases the surface area of the grinding and screening panels inside the hammer mill, which in turn provides increased grinding and ringing capacity.