Generating steam entails more than just “putting the kettle on” (2)

Easily manipulated processing variables include steam pressure and conditioning temperature; the pressures and temperatures utilised for steam conditioning. Robert Veenendaal makes a living of advising on steam generation in plants. In this second article on steam issues in the feed industry he focuses on what happens after the fire for the kettle is lit.

To generate steam we need heat, which is provided by some sort of fuel. Fuel is a difficult issue, because of price and it is not always environment friendly. The cheapest calories to burn are probably from coal, but this source has negative problems like storage, moisture content, volatile matter, ash removal, fire hazard, dust control and the environment. For a comparison: 1.5 kg of coal or 1.05 m3 of gas is needed to make 1 litre of distillate. The control of CO ppm is more difficult with coal and residual fuel than by burning gas. Maintenance-wise gas is cleaner to use, while coal and residual fuels often have carbon build up in the tubes, combustion reversing chamber and smoke boxes that will also lower the efficiency. Coal-fired boilers are the most expensive to purchase.

In practicse, I always find that the combustion settings are very high on excess air, with higher than usual stack temperatures and often a low efficiency percentage due to the high temperatures in the chimney. The ideal combustion setting is Low Fire – oxygen levels are around 6.0%, Middle Fire 5.0% and High Fire 4.0% for the step burners. For full modulating burners start with 10% load and increase that with 10% to full load and then we see the oxygen percentage gradually decrease from 6.0% to 4.0% in small steps of 0.2%. There will still be enough excess air to cover small fluctuations in air temperature and tolerances of calorific values in fuels. When stack temperatures are excessive above the 220ºC by High Fire this is often due to scale build-up, carbon build-up or excess air.

Pressure settings

Pressure setting of the boiler is 8.0 – 8.75 Bar. It is not required to bring the pressure up to higher levels, which will only result in waste. Pressure to pelletise is much lower so we don’t really need high pressure only to transport steam in the pipe. Pipe sizing and pressure are related to volume of steam that needs to be transported. This is called pipeline capacity and velocity or volume and speed. We often see a smaller size valve (strainer, check valve, pressure regulator) installed than the size of the steam pipe. This will create a bottleneck and reduce the volume of steam to the press.

To distribute steam to presses and tanks etc. we should make use of steam headers that are small steam vessels with steam in and outlets. There should be a header in the boiler room and in the feed mill. When using a number of presses, an extra header can be installed so that each machine even far away from the steam header will have a stable pressure. In this way also parts of production for maintenance or other purposes can be isolated. Pipeline capacity and velocity form the bases of transporting steam.

Steam trapping

When pelletising it is important to supply dry steam and if required always isolate a steam trap, because wet steam causes slipping resulting in a press clean out, a start up again and production time loss of 15-20 minutes at the minimum. To avoid this, always install in each steam header a steam trap assembly,with the condensate return connected to the main condensate return line back to the boiler feed water tank. Before the pressure reducing valve we have a water separator with a steam trap assembly and just before steam enters the press we again have a steam trap assembly. Each steam trap assembly has a check valve, a strainer, three isolation valves and a steam trap, size ¾ inch.

It is very important to feed back all condensate and flash steam. For the steam trap assembly sized ¾ inch for horizontal transport of condensate a ¾ inch pipe is sufficient, but when the condensate has to go up to a higher level into the main condensate line it is better to reduce the pipe size to ½ inch. If the pipe goes down it will not be reduced.

The main condensate pipe should not be too small, because it will create back pressure. Each connection into the main condensate pipe should enter from the top under 45 degrees in the direction of the flow. Each time the thermo dynamic steam trap releases condensate, some flash steam will push the condensate out. This flash steam can be used to heat up the condensate or boiler feed water tank.

Before and after the pressure regulator, a Mano or pressure meter should be installed. One of 0-10 Bar and a second of 0-6 Bar with a cock valve and siphon, so the Manometer can be isolated by mall function. There is no need to install a safety valve but make a smaller size by-pass to reduce the steam volume. The pressure setting should be set when the steam valve to the press is closed and not to the pressure we see when the press is running. When you reduce the steam pressure you also reduce the capacity of steam.

Saturated and super heated

By looking at steam tables we can see that pressure is very much related to steam temperature. But after the pressure reducing valve we will still measure a steam temperature of around 150ºC while the pressure is set around 1.8 Bar. That is super heated steam. Saturated steam at 1.8 Bar should have a temperature of 131.7ºC. Pelletising can only be done with super heated steam. It is a good idea to install a thermometer and pressure meter just before the steam inlet to monitor pressures and temperatures. From those meters you’ll see when steam becomes wet because the temperature will drop while the pressure is constant. If so, open the by-pass valve for a few seconds which is often enough to solve the problems. By lowering the operating pressure, the temperature will only drop by 1 or 2ºC . When manufacturing 24/7 there is usually no problem with starting up, only on Monday morning. There will only be one way to start up to supply steam to the presses:

• 1st Slowly open the valve from the boiler to the steam header,

• 2nd Open the valve of the steam header slowly until pressure is stable,

• 3rd Close the isolation valves just before and after the steam trap and open the by-pass valve. After about 30 seconds close the by-pass and open the isolation valves before and directly after the steam trap, and

• 4th Now you can open the valve for steam out to the steam header No. 2 and everything will repeat.

Note: when fully opening a steam valve turn the valve once in a clockwise direction. Now you can easily work out if the valve is open or closed. When fully closed and cold and steam starts to flow through the valve, it will get hot and it will be very difficult to close or open it.

Ideal pressure

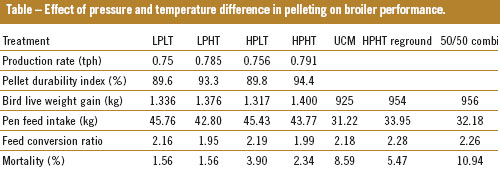

The ideal pressure setting for pelletising is around 1.8 Bar. It can be lower as a result of opening the steam valve; only little quantities of steam will enter the press and you can see that the amperage only goes up slightly. At lower pressure you can open the steam valve much further and the output of the press will increase as well. Then you can start fine tuning. A little more feed requires a little more steam. Immediately you will see an improvement in durability and decreasing dust. Pressure settings can only be adjusted with the steam valve when the press is closed. You will see that when operating, the pressure readings can be 0.9 – 1.5 Bar but that is not the set pressure, you have to close the steam valve of the press to find out. In almost all cases pressures can even run up to 5 Bar and never reach a proper output before it already starts slipping.

It is advisable to install an electrical or pneumatically controlled quick action valve just before the steam valve of the press, so that by slipping the valve can be activated by pushing the button and the steam valve will close immediately. There will be no steam flowing back into the feeder or conditioner and it is not required to clean it out. It will save very much in down time and product output.

Correct setting rollers

Part of output improvement is the correct setting of the rollers and knife. We often see operators adjusting the rollers or just after replacing, set the rollers exactly on the correct place with a minimum of space using a small piece of paper, thin carton or hard thin plastic. It has a very big influence on the output. If the space is too big it will lower the press output drastically and if the space is too small it will lower the output and shorten the life of the rollers. Also we have to watch the setting of the knife. All these little things will add up in production output, in the life of the die or life of the rollers. Try to keep a record of the life of those parts.Not all feed is the same and different formulas give different outputs. It is nearly impossible to do fine pressure adjustment for each type of feed. Also other factors can make an enormous difference in quality and output. When we look at the use of raw materials, for example soy, it will make or can make a difference in press output of up to 20%. It is just from which continent it originates. In some countries there is local supply and imported. Usually imported materials have lower water content and make pelletising easier. Moisture content of all raw materials should be carefully monitored. Seasonal influences like dry and wet season humidity can cause changes. Pelletising is very sensitive to these differences.