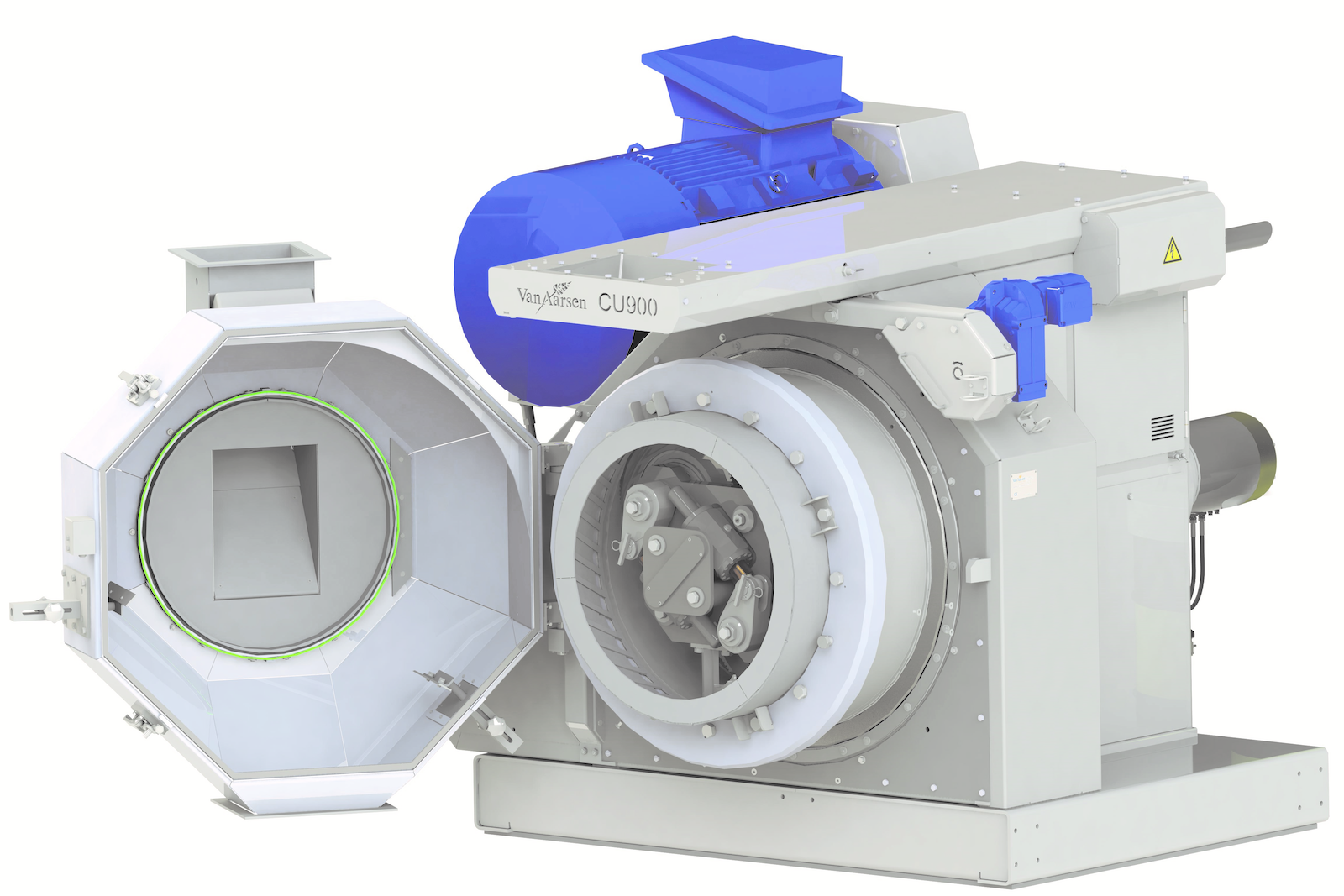

New generation pellet mill by Van Aarsen

Dutch company Van Aarsen introduces a new generation pellet mills with motor operated roller adjustment and active roller slip control at the upcoming Victam Asia.

These functionalities provide an optimised operation and the opportunity to experiment with the roller distance and steam addition for the recipes to boost the feed quality and production efficiency.

The key of an efficient pelleting process is to determine the optimal compromise between energy consumption and pellet quality, while producing the desired capacity. Many factors are of influence on the pelleting process, from the recipe, to conditioning parameters, and pellet mill settings. The robust designed motor-operated roller adjustment enables the operator to easily choose the desired roller distance to the die, even when the pellet mill is in full operation. Together with the intelligent software, this system offers recipe controlled pellet mill operation.

Also interesting: Kronan feed mill: the crowning glory of Van Aarsen

Save on maintenance

Another benefit is the increase of life of the die and rollers up to 30%. By linking the operation of the dosing screw to the roller distance, the rollers will retract when the pellet mill is not producing. Furthermore, the system is equipped with a die cleaning mode, enabling the operator to clean the die after a batch. This will also provide a quick start-up of the pellet mill after a standstill, because the product doesn’t get the opportunity to cake onto the die.

A trouble free pelleting process

The active roller slip control is another intelligent system designed to optimise the pellet mill production rate. This system detects roller slip and activates the system to automatically resolve the slip if desired, reducing the downtime of the pellet mill due to roller slip to nil. It also offers you the opportunity to experiment with the roller distance and steam addition for the recipes to boost the feed quality and production efficiency. You can rely on this system while exploring the settings for the most optimum production.