New vacuum coater to optimise fish feed

Vacuum coating or vacuum infusion processes are widely known in the fish feed ?industry as well as in the ?pet food industry. This type of equipment enables the feed manufacturer to produce ?high-fat feed of an ?outstanding quality.

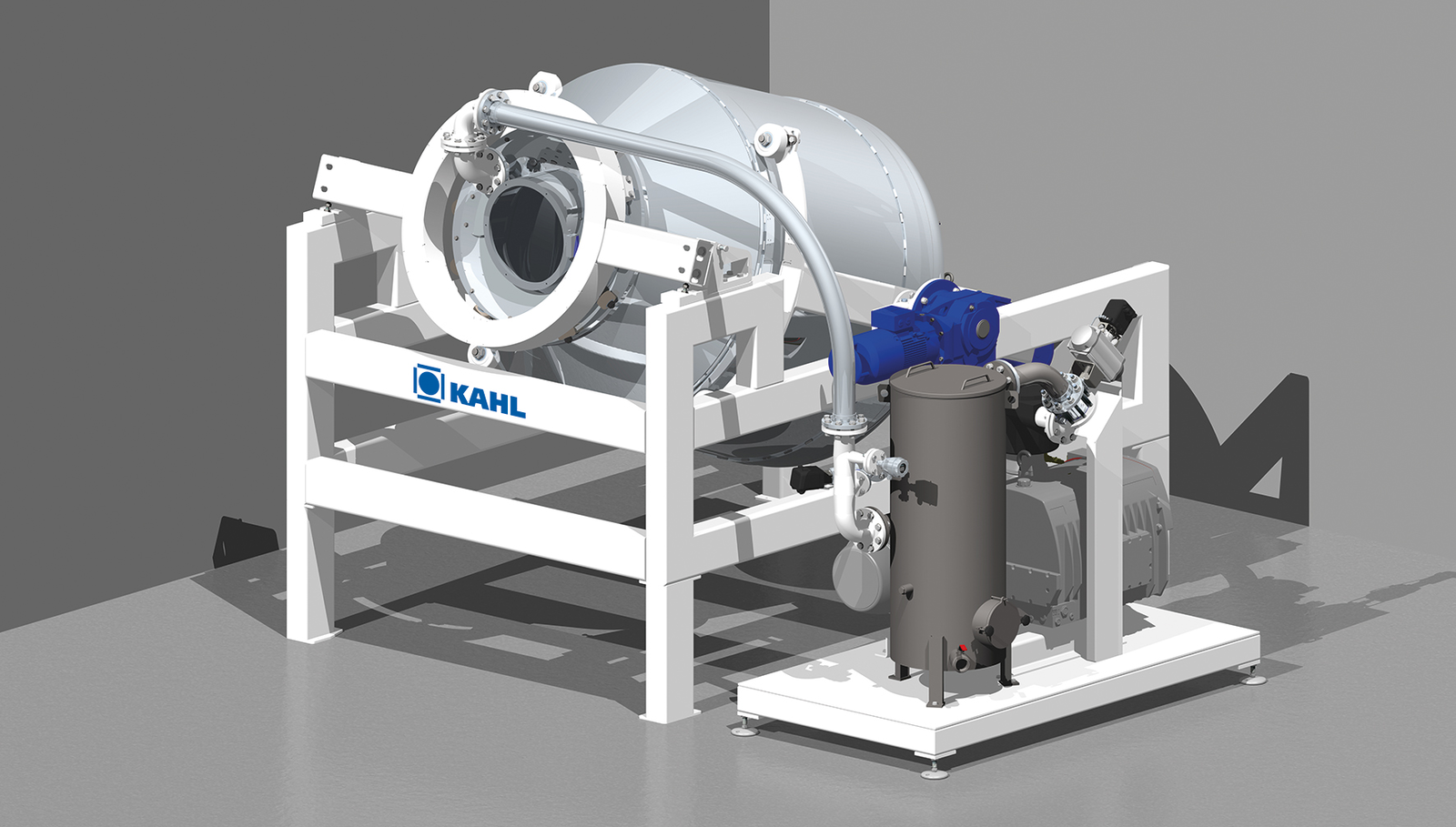

With these processes, liquids can be introduced in a feed crumble (extrudate, expandate, pellet, etc.) or pet food kibble in a way that they are protected against degradation by the surrounding environment. Amandus Kahl, together with the Centre for Feed Technology, Norwegian University of Life Sciences, has designed a complete new type of vacuum coater to overcome the known obstacles of degradation.

Decreased amount of fines

Abrasion of the product inside the traditional coaters and mechanical impact due to the fast rotating mixing elements result in an increased amount of fines. Additionally, the mechanical impact promotes micro cracks, which act as weak spots. As a consequence, these weak spots promote breakage of the feed while the product undergoes handling procedures after the coating process. In case of aquafeed, where breakage can also occur in the long feeding hoses before spreading the pellets into the cages, the micro cracks can result in an observable amount of additional fines. The new vacuum coater is designed as a rotary drum mixer with no moving parts inside the mixing chamber. Tests showed a significantly decreased amount of fines in comparison with twin shaft mixers. Also the amount of micro cracks inside the feed was significantly lower. Hence the overall product quality was improved significantly.

Reduced energy consumption

The double positive effect of this vacuum coater reduced fines on site, and reduced possibility of breakage after the pellets left the feed plant, also has an environmentally positive impact, in addition to the obvious economical one for the feed company. Less fines means less feed reprocessing and reduced energy consumption. Less breakage after the feed has left the plant ensures that the loss of feed is minimised. Furthermore, the machine can be easily cleaned, as it allows complete accessibility to all parts for reliable and fast cleaning when required.

Conclusion

According to the producers of the new vacuum coater, the design allows reduced feed waste, both in the feed plant and during handling later on in the process, which in general will increase customer satisfaction for the feed. Reduced feed loss, also equals reduced environmental impact. In addition the improved ease of maintenance and cleaning reduces operational costs for the feed producers.