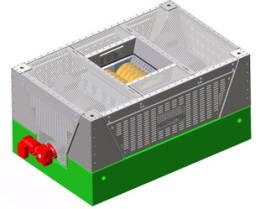

Research: Grinding performance of the multicracker system

At Wageningen University, The Netherlands trials have been carried out to obtain data on the grinding performance of wheat, maize and soybeans in a multicracker system.

The multicracker was introduced to the market in 2005 as an alternative to the more common particle size reduction systems, such as hammer and roller mills or a disc mill.

The multicracker technology is based on the cracking action of two rows of discs.

Schematic diagram of twin parallel shafts in the multicracker grinding system: view from above.

1, Adjustable gap;

2, disc surface;

3, discs;

→, disc revolvement direction.

Trial setup

Wheat, maize and full fat soybeans were ground by this multicracker system to study the effects of disc type (ceramic versus steel discs), disc speed in revolutions per minute (2,650 versus 3,800 rpm), throughput (3.43 versus 6.70 metric t/h) and the gap between the discs (0.11 versus 1.04 mm).

Mean particle size, width of the particle size distribution curve and total and specific mechanical energy consumption were the dependent variables under investigation.

Detailed image of multicracker grinding elements:

Ceramic grinding elements (top left);

Detail of surface of a ceramic grinding element (top right);

Steel grinding elements (bottom left);

Detail of surface of a steel grinding element (bottom right).

Results

Maize, soybeans and wheat had different grinding characteristics in the multicracker system with mean particles sizes of 1.76, 2.10 and 2.08 mm, respectively.

The width of the particle size distribution, however, was not different for the different seeds.

The mean particle size of the initial whole ingredient divided by the mean particle size of the ground samples, referred to as the reduction ratio differed largely between the seeds.

For maize the reduction ratio was 4.53, for soybeans 2.76 and for wheat 1.71.

All particle characteristics of the ground ingredients (mean particle size, width of the particle size distribution and reduction ratio) were not affected by the capacity of the installation in the range of 3.43-6.70 t/h.

Soybeans showed the highest specific mechanical energy (2.8 kWh/t) at the highest mean particle size compared to maize and wheat (2.1 and 1.8 kWh/t, respectively).

Disc type was examined to be an important variable that largely affects all particle characteristics as well as the consumption of specific mechanical energy, steel discs revealing the lowest energy requirements.