Soy-based pellets : A game-changing feed for farmed tuna

As everyone involved with tuna aquaculture well knows, a replacement is needed for feeding bait fish such as mackerel, sardines and herring. The company Ichthus Unlimited has found the answer: Soy-based pellets.

“Using baitfish is a big problem for the global tuna farming industry,” says Alejandro Buentello, president of Ichthus Unlimited. The firm is based in the US (Iowa, California, and Texas) and Madrid, Spain and has 15 employees.

Challenges of baitfish use as feed

“Baitfish is, of course, wild caught and presents food versus feed concerns as well as sustainable stock level concerns,” says Buentello. It’s also in many cases, caught, frozen and shipped long distances to tuna farms, which makes the carbon footprint of farming tuna huge. Foreign baitfish can also introduce exotic pathogens that can decimate endemic fish because pathogens are not killed by freezing. When you thaw the baitfish before feeding, the fat, blood and other organic materials leak out of baitfish and with ocean wave action, form a smelly, foam-like material. In the Mediterranean, this commonly causes tourists to complain and governments of Malta and Croatia to temporarily shut down tuna farms in a never-ending cycle.”

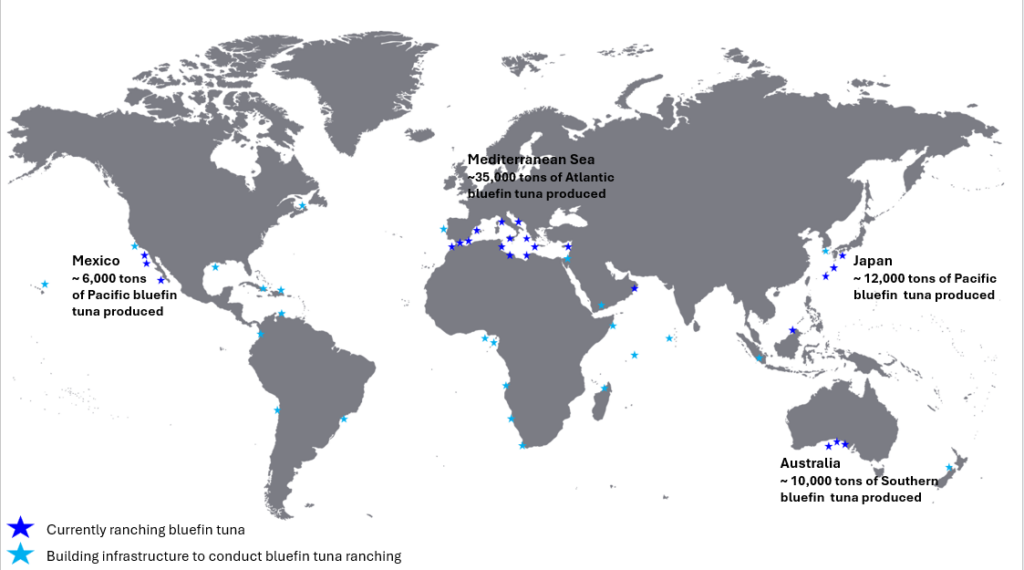

Buentello adds that tuna farms in Mexico, Australia, Japan and many other locations also use wild-caught bait fish shipped from other parts of the world. Feeding tuna baitfish has repeatedly caused the pilchard fishery in Australia to collapse, he says, and poses serious ecological risks elsewhere.

Pieces of bait fish also go to waste. They drop down through the bottom of the cage onto the ocean’s floor below the tuna cages and/or are eaten by sea lions. Birds snatch pieces at the surface. The broken pieces (in addition to the foamy sludge from thawing) result in a lot of nutrients being added to the ocean environment around the cages.

Due to all these issues with baitfish as feed, initiatives such as the Monterey Bay Aquarium Seafood Watch Program and certification bodies such as ASC, the Global GAP and the Global Seafood Alliance currently do not certify bluefin tuna farming.

Can tuna farmers achieve sustainability? Ichthus Unlimited has found the answer.

A long journey

Many aquafeed companies have tried to make tuna feeds, but have had trouble with costs, texture and palatability. Tuna fish completely reject extruded pellets.

However, over the last 20 years, the Ichthus team has carefully developed a large, specialised soy-based pellet that the tuna eat really well – and one that also completely prevents nutrient loss. Finally, it is hitting the market.

“It’s got the right mouthfeel, texture and moisture content for tuna and they love it,” says Buentello. “Each pellet is about the size of a mackerel, and they eat it rapidly, so none is lost to birds or other opportunistic animals. No pieces or nutrients are lost to the environment. Larger tuna actually learn that they can eat several pellets at a time.”

These pellets have already been used very successfully in Mexico, Spain and Malta. Through toll-manufacturing partners in the US and Spain, Ichthus has already produced large tonnage in Europe, but it’s only been small amounts so far compared to what the market needs. However, by the end of the year, an important scale-up is planned.

“We are focused on the Mediterranean market because it is a hub for tuna farming,” says Buentello. “Over 80,000 tonnes of compound tuna feed may be needed every year in the Western Mediterranean region. There are quite a few farms and tuna consume about 7% of their body weight each day. There are also very limited bait fish resources available in the Mediterranean. It’s mostly imported from the Baltic Sea, Portugal and the UK. We will gradually scale up.”

Compound feed benefits

In addition to its environmental benefits and lack of waste, using the compound feed pellets imparts nutritional benefits to tuna and improves performance, says Buentello. Flesh colour is improved and mercury content is significantly reduced. Feed conversion ratio is markedly improved (~ 6-fold), while farmers also achieve logistic and financial benefits. Ichthus’ feed is also scalable, allowing tuna farming to grow sustainably.

Using this feed will also greatly help farmers with the diversification of their global tuna markets. Buentello explains that traditionally Japanese buyers pay the lowest price for Mediterranean-ranched tuna but consume by far the largest volumes. “Even though there are several Japanese buyers, prices are mostly set during tuna auctions at the Toyosu fish market in Tokyo,” he says. “This creates uniformity in the prices being paid at any given time, effectively resulting in anti-competitive practices that make Mediterranean tuna farmers more vulnerable to price reductions. For example, farm prices of ranched tuna paid by Japanese buyers dropped approximately in half from 2022 to 2023, resulting in great financial distress for Mediterranean farmers.”

However, if farmers can use Ichthus’ compound feed and attain sustainability certification, they will have access to the sustainability-conscious retail market where sourcing farmed bluefin tuna is currently avoided.

Inside the pellet

The Ichthus tuna feed pellet contains a specially-developed blend of ingredients. It’s also made with a unique manufacturing process that prevents nutrient loss and, as mentioned, provides the correct texture and mouthfeel.

To bring down binder costs, the Ichthus team has looked at soybean hulls. Due to large amounts of soybean now being grown in the USA for food and biofuel manufacture, there is an increasing amount of soybean hulls available. These by-products of soybean processing have been mostly fed to dairy cattle so far because monogastric species (including carnivorous fish such as tuna, poultry and pigs) can’t digest them.

Two years ago, Buentello and his team started collaborating with scientists at Auburn University (AU) to see if a binder developed from soybean hulls could perform as well as commercially-available synthetic binders or binders made from starches from crops such as corn, tapioca and wheat. For its efforts on soybean hull binder development (which can be used in aquaculture pellets and other types of pellets as well), Ichthus was a runner-up winner of the 2023 Soy Innovation Challenge.

“Preliminary testing has been conducted with warm-water species such as Pacific white-legged shrimp,” Buentello reports. “Further performance and functionality must be demonstrated in terms of pellet expansion during heat extrusion and ensuring we can achieve the proper density of the pellet so that it sinks or floats depending on the farmed species.”

Ichthus is seeking funding support to further develop the binder and test it in collaboration with AU for shrimp, the US Fish and Wildlife Service for rainbow trout, the University of Illinois for dogs, Texas A&M University for beef cattle and Cornell University for dairy cattle. Competitive funding support is being pursued from the United Soybean Board, the US Department of Agriculture (USDA) Small Business Innovation Research and Technology Transfer Program and other suitable initiatives.

Moving forward

In 2021, Ichthus built a tuna hatchery near San Diego, California on a pilot scale, the first tuna hatchery in North America. There, the company successfully produced Atlantic and Pacific bluefin tuna as well as yellowfin tuna from eggs. (Also note that in July 2023, scientists at the Spanish Institute of Oceanography closed the life cycle of Atlantic bluefin tuna in land-based tanks for the first time.)

Ichthus is currently aiming to establish a commercial tuna hatchery in the US Gulf of Mexico. With hoped-for funding from National Oceanic and Atmospheric Administration (NOAA) National Aquaculture Initiative and the USDA-National Institute of Food and Agriculture program, the company plans to build a new hatchery on a re-purposed oil platform that also incorporates renewable energy applications. To do this, Ichthus is partnering with Blue Silo Aquaculture and the Texas Sea Grant College Program as well as with several universities including Texas A&M, University of Montana, the National Science Foundation and NOAA’s Southwest Fisheries Science Center.