The individual drive in the crushing roller mill revolutionises feed production

The issue of animal welfare in livestock farming has become increasingly important in recent years. Consumers are paying more attention to the conditions under which the animals were kept. The very foundation of animal welfare is already laid during feed production. Manufacturers have to meet a wide range of requirements depending on the animal species and age group. The crushing roller mill, which is already established in the feed industry, now uses a new technology that allows the individual needs of the animals to be taken into account already during feed production.

Anyone who keeps farm animals may only do so in compliance with the standards regulated in the Animal Welfare Act and the Order on the Protection of Animals and the Keeping of Production Animals. It takes the cooperation of all parties involved – politicians, veterinarians and livestock farmers – to achieve the national objective of animal protection that is enshrined in the German Constitution. In the paper “Need for Research and Innovation, Farm Animals”, the Federal Ministry of Food and Agriculture deals with the breeding objectives in modern livestock farming. Apart from the main performance characteristics such as milk yield and weight gain, they also include animal welfare indicators such as animal health combined with appropriate nutrition and feed conversion – another reason why feed manufacturers are constantly developing new formulae for optimum animal feeding.

Anyone who keeps farm animals may only do so in compliance with the standards regulated in the Animal Welfare Act and the Order on the Protection of Animals and the Keeping of Production Animals. It takes the cooperation of all parties involved – politicians, veterinarians and livestock farmers – to achieve the national objective of animal protection that is enshrined in the German Constitution. In the paper “Need for Research and Innovation, Farm Animals”, the Federal Ministry of Food and Agriculture deals with the breeding objectives in modern livestock farming. Apart from the main performance characteristics such as milk yield and weight gain, they also include animal welfare indicators such as animal health combined with appropriate nutrition and feed conversion – another reason why feed manufacturers are constantly developing new formulae for optimum animal feeding.In addition to basic physiological factors such as digestion and nutrient requirements of individual animal species and breeds, also the animals’ age and their utilization are important. Be it sows in pig or lactating sows, piglets or fattening pigs, turkeys, laying hens, broilers or dual purpose chickens – their individual needs vary greatly.

At the same time, it is a proven fact that the use of high quality feed improves the production performance through its influence on the well-being of farm animals. Valuable components such as starch and proteins can only be broken down by the animals’ digestive enzymes if they have been processed appropriately. Optimal grinding can, among other things, reduce gastrointestinal diseases of numerous farm animals and thus performance losses.

High-quality feed requires high-quality grinding

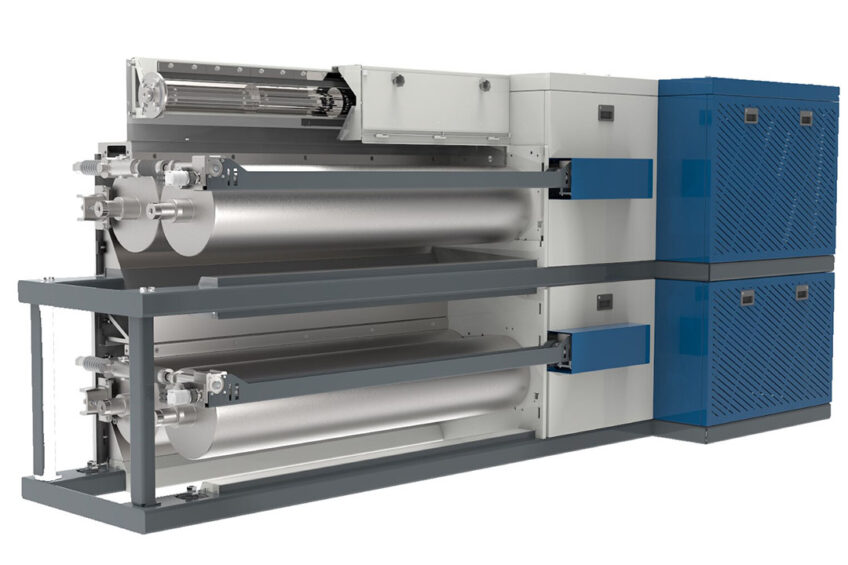

This is where the crushing roller mill comes into play. As a crushing machine, it has always been used to grind grain and legumes such as maize, wheat, barley, rye and oats, but also soybeans, rapeseed, lupins, peas and field beans. As an alternative to the hammer mill, the crushing roller mill is suitable for the production of somewhat coarser feed rather than for fi ne grinding. This is achieved by two counter-rotating, corrugated rollers that break up the respective grain into small particles. For this to be possible, the rollers rotate at different speeds so that the desired cutting effect is produced as a result of pressure and shear stress between the sharp cutting edge and the non-cutting edge. The energy consumption is significantly lower than that of the hammer mill. Furthermore, the machine is equipped with very few wear parts and therefore requires very little maintenance and is highly reliable.

The individual drive increases the flexibility in feed production

The new version of the crushing roller mill is a novelty on the market. It is no longer equipped with the traditional central drive, but with frequency-controlled individual drives with energy recovery. It has been developed by the company AMANDUS KAHL, an expert in the construction of machines and plants for the compound feed industry. “Animal welfare in connection with animal nutrition has been a key issue at AMANDUS KAHL for years,” explains Felix Tometten, animal nutritionist at KAHL. “Our crushing roller mill revolutionises feed production in that manufacturers have even more influence on the grinding result owing to flexible setting options. Thus they are able to adapt the recipes to a wide variety of their customers’ requirements. This is a huge advantage in terms of animal health.”

For rollers with a diameter of 400 millimetres and a length of 1,500 or 2,000 millimetres, the throughput per hour is around 20 to 80 tonnes. Moreover, the compact machine is characterised by low power requirements and smooth operation. The technology is suitable both for individual components and for mixed products, especially for laying hen feed and other poultry feed as well as for pig feed.

Functioning and technical parameters

The new drive design has a particular advantage over the reduction gear previously used. In addition to the size of the grinding gap, the speeds of the two counter-rotating, corrugated rollers made of surface-hardened special steel can now be adjusted individually – even during operation. This influences the so-called lead, which denotes the speed difference of the rollers. The lower the differential speed, the lower the fines content in the final product and vice versa. The speed ratios can also be reversed if required, which influences the resulting structures. Further options are the different corrugations that can be refluted up to eight times, depending on the product to be crushed, as well as the option of single-stage or two-stage crushing. In the case of two-stage crushing, two pairs of rollers are arranged on top of each other Depending on the input product and the desired grinding result, users have the option of operating the roller pair in “sharp to sharp” or “dull to dull” mode. Thus, not only the size of the end product

is determined, but also the type of processing. In the operating mode “sharp to sharp” the grain is broken or cut, while it is crushed in the operating mode “dull to dull”. As a result, the grinding result is significantly optimised.

Functioning and technical parameters

The new drive design has a particular advantage over the reduction gear previously used. In addition to the size of the grinding gap, the speeds of the two counter-rotating, corrugated rollers made of surface-hardened special steel can now be adjusted individually – even during operation. This influences the so-called lead, which denotes the speed difference of the rollers. The lower the differential speed, the lower the fines content in the final product and vice versa. The speed ratios can also be reversed if required, which influences the resulting structures.

The new drive design has a particular advantage over the reduction gear previously used. In addition to the size of the grinding gap, the speeds of the two counter-rotating, corrugated rollers made of surface-hardened special steel can now be adjusted individually – even during operation. This influences the so-called lead, which denotes the speed difference of the rollers. The lower the differential speed, the lower the fines content in the final product and vice versa. The speed ratios can also be reversed if required, which influences the resulting structures.

Further options are the different corrugations that can be refluted up to eight times, depending on the product to be crushed, as well as the option of single-stage or two-stage crushing. In the case of two-stage crushing, two pairs of rollers are arranged on top of each other.

Depending on the input product and the desired grinding result, users have the option of operating the roller pair in “sharp to sharp” or “dull to dull” mode. Thus, not only the size of the end product is determined, but also the type of processing. In the operating mode “sharp to sharp” the grain is broken or cut, while it is crushed in the operating mode “dull to dull”. As a result, the grinding result is significantly optimised.

Renaissance of a classic

Renaissance of a classic

The crushing roller mill with individual drive ensures an even more specifi c adjustment in crushing of individual components for feed production. The crushing roller mill can also reliably process grains such as rye and barley that have been diffi cult to process so far. The combination of variable gap and variable speeds through the individual drives provides many options for adapting the formulae to the customers’ specifi c needs. “From barley and oats to very fi nelyground rye for sow feeding, a wide variation of granulations is now possible on a single machine due to the individual drive,” Felix Tometten sums up. The AMANDUS KAHL crushing roller mill with the new drive design is experiencing a renaissance. Its special features are all about enhancing animal welfare through optimal animal nutrition.