Fungus produces new feed type from corn stillage

A fungus grown in the leftovers of ethanol production could be a good energy feed for pigs and chickens, but also reduce energy costs, a finding at Iowa State University in the US shows.

In separate feeding trials piglets and chickens were fed high-protein fungi that Hans van Leeuwen and other ISU researchers have produced in a pilot plant that converts ethanol leftovers into feed-grade fungi.

In these feeding trials, researchers have found pig performance wasn’t impacted when dried fungi were substituted for corn or soybean meal. They are still studying the effects of the feed on amino acid availability, tissue growth, and intestinal health.

The production process also cleans some of the water used to produce ethanol, boosting the amount of water that can be recycled back into biofuel production and saving energy on water cleanup and co-product recovery.

Patent pending process

The fungi-production process was developed by a research team led by van Leeuwen, a professor of civil, construction and environmental engineering.

Van Leeuwen and the research team have been working on their “MycoMeal” process for several years. It began as an idea to improve the dry-grind process used to produce ethanol from corn.

The process has two patents pending and has won several major awards – most recently it was named the global grand winner of the International Water Association’s 2012 Project Innovation Awards in Applied Research.

For every litre of ethanol produced, there are about five litres of leftovers known as stillage. The stillage contains solids and other organic material. Most of the solids are removed by centrifugation and dried into distillers dried grains.

The remaining liquid, known as thin stillage, still contains some solids, a variety of organic compounds and enzymes. Because the compounds and solids can interfere with ethanol production, only about 50% of this thin stillage can be recycled back into biofuel production. The rest is evaporated and blended with distillers dried grains (the solubles).

Quick growing fungus

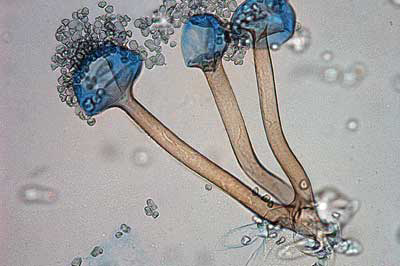

The Iowa State researchers add a fungus (Rhizopus microsporus) to the thin stillage and it feeds and grows and can be converted into easily harvested pellets in less than a day.

The fungus removes about 60% of the organic material and most of the solids, allowing the water and enzymes in the thin stillage to be recycled back into production.

The fungus is then harvested and dried for animal feed which is rich in protein, certain essential amino acids, polyunsaturated oils and other nutrients.

It can also be blended with DDG to boost its value as a livestock feed and make it more suitable for feeding pigs and chickens.

Van Leeuwen hopes the fungal product could one day be a low-cost nutritional supplement for people.

Million dollars savings

Van Leeuwen said the production technology can save US ethanol producers up to $800 million a year in energy costs. He also said the technology can produce ethanol co-products worth another $800 million or more per year, depending on how it is used and marketed.

Researchers have developed a 400-gallon (app. 1,500 litres) pilot plant at the Iowa Energy Center’s Biomass Energy Conversion facility in Nevada to test and refine the process.

They are producing a tonne of the fungi this year for the animal feeding trials, which van Leeuwen said is no minor feat for a pilot plant. There has been some commercial interest in the process, he said.

The project has been supported by a three-year $450,000 grant.