“The feed market is changing and we have to adapt”

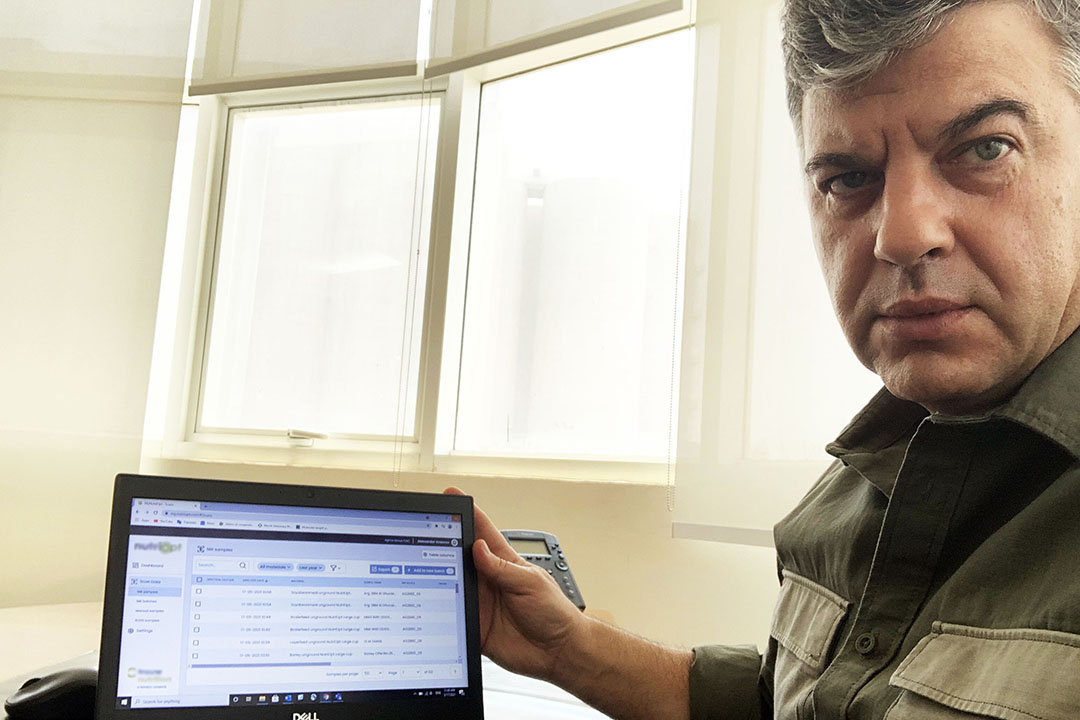

A strike in the port of Argentina, logistic issues due to the Covid-19 pandemic and dealing with new suppliers and origins. “It is all part of the game,” says Dr Aleksandar Andonov from one of the biggest feed mills in Abu Dhabi. Using MyNutriOpt from Trouw Nutrition helps this feed mill stay in the lead.

The animal feed industry is a complex business, says Dr Andonov, Senior R&D Manager Feed from the business unit ‘Agri Business’ from the Agthia Group in Abu Dhabi. Although this leading feed producer in the United Arab Emirates (UAE) rarely faces serious quality issues due to strict quality specifications and procurement procedures, there are always unpredicted circumstances to deal with. “Natural circumstances such as the weather or unforeseen issues such as delays in shipments because of strikes and availability and logistic problems due to the current pandemic means that we have to adapt to different quality specifications and origins than we used before. This means that we also see more deviations in raw material quality,” says Dr Andonov.

A leaner, more simplified process

“To deal with the deviations in raw material quality, it is pivotal to have the data and insights on the consistency in quality of batches readily available when we need it,” Dr Andonov addresses. This is the reason why the Agthia Group decided to start using the NIR services for rapid and accurate feed analysis. “Our NIR equipment is connected with the MyNutriOpt portal from Trouw Nutrition, where we can view and manage the feed data in one single place. When a raw material or finished feed sample is scanned and analysed, the data is synchronised in real time in the MyNutriOpt portal,” Dr Andonov explains. Nutritionists and quality controllers log in to the portal to access the latest analyses, shown on the MyNutriOpt dashboard. The results are automatically synchronised and real-time shown in this online portal and hence accessible for all people that need to work with the data, such as quality assurance and control (QA/QC), nutritionists and procurement. Dr Andonov praises the efficiency gains and speed since working with MyNutriOpt. “I don’t have to call the QA/QC lab anymore or wait for the weekly or monthly lab reports to gain insights in the feed analysis data. The information I need is with me already because I simply log in to the portal. This makes the processes for all departments leaner and more simplified.”

Detecting quality issues earlier

As the Senior R&D Manager Feed, Dr Andonov and his team are responsible for feed formulation and technical support and use MyNutriOpt daily. “We use routine sampling of the raw materials and the great thing about MyNutriOpt is the ability to create batches of a certain raw material to monitor overall consistency or contaminations over time, instead of relying on the data from individual samples. This is very important for stored materials. They may look fine when they come in and you expect homogeneity of the material, but the quality can change when they are stored, or the batch can have other (unwanted) material in. The other day, we saw that a batch of soybean meal was losing quality in storage. We were able to detect this quite quickly, because of the amount of data points we had for this batch and the clear visualisation of the data in MyNutriOpt. When delving deeper into the possible causes of the problem, we found out that the raw materials did not get proper heat treatment at the supplier, reflected in outliers of trypsin inhibitor (an anti-nutritional factor). We then removed the low-quality batch from the rest,” Dr Andonov explains.

Making work processes more efficient

When it comes to feed formulation and updating feed matrices, Dr Andonov really sees the benefits of using MyNutriOpt. “In the past, I was manually calculating all the amino acids and metabolisable energy estimations based on the proximate analysis. This is not only a lengthy process, but also prone to errors. Now we are working with the concrete proximate analysis data from NIR and in MyNutriOpt, the other parameters / additional data are calculated automatically for me.” For Dr Andonov, the extra data, such as all digestible amino acid values, are crucial to formulate diets that come as close to the animal’s requirements as possible. Also feed matrices can be updated more often, because of the better insights in the deviations of the raw materials. It also influences the overall QA/QC process. Dr Andonov: “With MyNutriOpt we can also make use of all the data, simply because we have a better overview and accessibility. This has improved the workflow in our company, reflected in optimised reporting and testing plan processes at QA/QC, more accurate diets and less manual calculations for the formulation department and better decision making, price setting and supplier management for procurement.”

More flexible and agile than ever

“When you can rely on your common suppliers you don’t have issues. But the market is changing, and we must adapt. We need to be flexible and well informed to make the right decisions. This is especially the case when we have shortages of certain raw materials. We need to quickly decide which direction we take, if we need more of a certain raw material or less, and from which region. We therefore need a tool such as MyNutriOpt more than ever. For our company it provides the functionalities and data that we need to further improve operational efficiency, flexibility and agility,” Dr Andonov concludes.

Learn more about MyNutriOpt and the NutriOpt services and solutions at: www.nutriopt.com.