More efficiency with automatic lubrication of pellet mills

Every machine has to be lubricated and Leding in Van Buren, Arkansas, USA has made this to its speciality. Recently automatic lubrication has become of interest to pellet mill manufacturers.

Leding has owned Leding Lubrication for the last 15 years, and has sold oil and lubricants for 20 years. He sees real potential for growth in the demand for automatic lubrication machines.

“Automatic lubrication is in its infancy,” Leding explained. “The farther north you go, the more of it there is.”

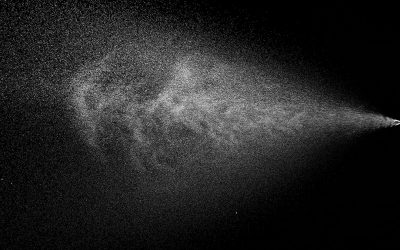

Leding described how one of his automatic lubrication units worked on a California pellet mill making poultry feed.

“What this does, it applies small amounts of grease to the bearings every 15 minutes,” Leding said. “It’s adjustable in a text screen, so it knows how much grease to use, so it uses less grease over all. It also shows when it’s out of grease.”

The system is not cheap. A complete unit similar to the one on the California pellet mill could sell for around $15,000.

But the big price tag means increased efficiency for the customer. The biggest advantage with automatic lubrication is that the machines can be greased more frequently and while in operation.

“You can have constant lubrication without having to stop the machine,” Leding said.

He stressed that the advantages of his automatic lubricators are increased efficiency and savings.

Flexible manufacturing

Leding Lubrication is very flexible with its manufacturing, and most of its jobs are custom-designed for specific customers.

“Basically we can come up with a lot of things,” Leding said. “It’s what the customer wants, and we can make it.”

Leding Lubrication has two full-time employees and depending on demand, has three part-timers.

Unlike many employees today, Leding employees have some degree of job security. “I’ve been selling lubricants for 20 years,” Leding said. “Every machine out there has to be lubricated.”

For more information about automatic lubrication visit the Leding website.