Ottevanger Milling Engineers – craftmanship in the animal and food processing industry

In 2009 it was precisely a century ago that Dirk Ottevanger, a miller’s son, founded a regional windmill manufacturing company, laying the foundation for Ottevanger Milling Engineers BV. Nowadays Ottevanger plants can be found all over the world.

The company is one of the leading Dutch companies who have specialized in the design and manufacture of equipment and complete plants for the grain processing and compound feed industry.

The process of all our projects starts with a pre-study to find out if the project is feasible and if it can be carried out within a set budget. The next step is to start working on design, layout and technical specifications and a price calculation, followed by a definite design, purchase of materials and manufacturing of machines and steel works. After shipment to the plant location, the plant can be build under supervision of Ottevanger technical engineers. After starting up Ottevanger stays in contact with the client to support in training of employees, delivery of parts and maintenance.

The described process is the regular working order for every project, but Ottevanger also produces a revolutionary design feed mill, a containerized feed mill can be put together in a matter of weeks at a production site. From 2 tph to 30 tph a large variation of combinations can be made.

The containerised feed milling unit is built to the size of standard 20-feet (6 meters) containers. At the plant location the containers are stacked to form a complete mill. Feeds for different species can be produced. Separate units have been designed for production of petfood and treatment of raw materials, such as soybeans. The concept has also been developed for flour production.

The complete unit is pre-assembled in the factory, which reduces installation time on site by 80 percent. The complete electric control is part of the delivery and can be extended to a fully computerised system.

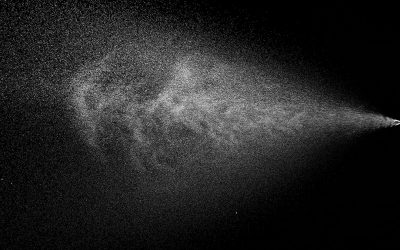

Our product range also includes mixers, hammer mills, pellet mills, conditioners, extruders, driers/coolers, crumblers, crushers, bucket elevators, screw conveyors, chain conveyors, liquid dosing systems, storage silos for grain and feed, spare parts, electric control and fully process automation, after sales service worldwide.

Ottevanger Milling Engineers

Moerkapelle – Aalten – Holland