Role of extruders in feed and pet food safety

According to the FDA, pet food is contaminated if it contains salmonella. Therefore, it is the pet food manufacturer’s liability to produce salmonella-free pet food.

By Mian N. Riaz , Head Extrusion Technology Program, Texas A&M University, USA

It is the feed industry’s responsibility to manufacture pet food of the highest quality and increase awareness all along the supply chain by using a comprehensive approach. They need to build confidence in consumer and regulatory agencies, and continually update and improve their programs. In any pet food plant, critical areas of concern for pet food safety other than extrusion are raw material, environment, finished product, and operators/workers. Pet food safety under normal conditions does not mean a seal of approval under “unusual” conditions. For example, most will agree that cow milk, eggs, peanuts, and tree nuts are safe to eat, but there are approx. 30,000 cases of anaphylaxis, 2,000 hospitalizations, and 150 deaths annually in the US because of these products not being safe.

According to Promar International Report, worldwide sales of dog and cat food was $27.5 billion in 1999. It is projected that in 2010, this figure will be increase and reach $41.3 billion. A total of 75% of pet food sales are in North America and Europe. According to one estimate, 64 million US households have at least one pet. Emerging economies, however, are increasing their share of the global market and by 2010 there will be over 180 million new customers. Pet food therefore needs to be safe and free from pathogens for consumers to handle, as well as for their pets to consume.

Extrusion

Almost 100% of pet food is extruded. There are several different types of extruders that can be used to make pet food. If an extruder is set up correctly and operated at the recommended temperature, we can assure that the pet food will be safe for human handling as well as for our pets. Unfortunately, though, this does not always happen and pet food is sometimes recalled because of the bacteria present in the food, or some form of contamination has occurred. According to one report, dry pet food has been connected to at least 79 Salmonella illnesses.

The feed industry is acutely aware of the need to eliminate the possibilities of food-borne illnesses from microbial contamination which can occur at any point along the food chain. Mandating that all feed be sterilized through processing was even considered by the US government as a means to ensure public safety. Even though the practical aspect of such a mandate is questionable, feed processing techniques such as extrusion are in place that could fill the requirements of this type of program. Extrusion can produce extremely safe pet food and feed if applied correctly and monitored for time/temperature.

Check raw materials

A major source of contamination of pet food is raw material, which may contain toxin, mould, bacteria, as well as salmonella. Extrusion cooking with a pre-conditioner has the ability to kill most of the pathogens, bacteria, and salmonella, and can greatly reduce the toxin in the feed. But one should be very careful after extrusion not to re-contaminate the pet food. Most of the pet food can become re-contaminated during conveying, drying, cooling, coating and packaging. There are several guidelines that can be used to minimise the risk of re-contamination. The first step to produce pet food free from Salmonella and other pathogens is to begin with the raw material.

A pet food manufacture must pay attention to raw material (dry and wet) when received at the plant. In general, most pet food formulations include corn and its products, like corn gluten and wheat, and products like wheat middling and soybeans. Some of these ingredients may contain naturally occurring toxins and some may contain anti-nutritional compounds. The following parameters must be carried out to get good quality raw material:

Incoming Dry Ingredients

– GMP must be followed.

– Testing for microbial in the dry mix.

– Ask supplier for traceability and history.

Incoming Wet Materials (fresh meat)

– Keep chilled, emulsified form which means 0-5°C, which should keep it stable for at least 48 hours.

– Heat treatments to 55-65°C kill microbes, but this requires additional equipment and labour.

– Stabilize the meat at room temperature by adding 3% phosphoric acid and 22% propylene glycol or similar preservatives.

Role of extruder in safety

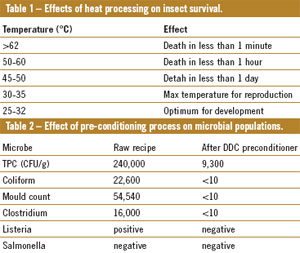

The main role of an extruder is to cook and pasteurize the pet food and feed in a very short time. Extrusion temperature is enough to kill most insects present in the raw material (Table 1). A majority of the microbes can be destroyed during the pre-conditioning process of pet food as shown in Table 2.

However, there are several factors that will affect the resistance of micro-organism. For example, water, fat, salts, carbohydrates, pH, proteins, and the number of organisms, age of organisms, growth temperature, inhibitory compounds, time and temperature, and effect of ultrasonic. Extrusion cooking will destroy the avian influenza virus when operated above 70°C and Newcastle Disease Virus can be inactivated by extrusion when operated above 75°C for one minute.

Aflatoxin is a secondary metabolite produced by fungi or moulds that are toxic and harmful to animals and humans. It can contaminate oilseeds and cereal grains – in the field and in storage – that may be used for pet food production. These are stable compounds that resist destruction by food processing. Mould and mould spores can also be destroyed during extrusion cooking. It should be noted that there are several different moulds that are heat resistant and may need a higher cooking temperature. In general, though, most of the moulds can be destroyed by cooking at 55-95°C. According to experts, extrusion can reduce 50-80% aflatoxin in corn without adding any chemical. By adding ammonia (hydroxide or carbonate) aflatoxin can be reduced by up to 95%. Similarly, aflatoxin can be reduced in peanut meal up to 23-66% without any chemical during extrusion. By adding ammonia during extrusion of peanut meal, 87% aflatoxin can be reduced.

The following parameters should be considered critical points during the extrusion of pet food:

1. Assume presence of salmonella in raw material (test for verification).

2. Establish heat, shear, pressure, and time parameters for the process.

3. Monitor, control, and document critical process parameters.

4. Contain/recycle under-processed material.

5. Test to validate the effectiveness of the process.

6. Release program.

During pet food manufacturing, critical control points, such as time and temperature, are set on pre-conditioner and barrel for proper heat treatment (Figure 1). The pet food manufacturer must validate the temperature and time by using appropriate thermocouples (flush mount vs. extended tip) and by calculating temperature and using mass-energy evaluations.

Below are a few extruder operating recommendations that should be noted.

• Always monitor kibble moisture using water activity metre.

• Minimum kibble sample number of 15 assuming a 95% confidence limit and 0.02 water activity bound (confidence interval)

• Always select upper water activity operating threshold.

• Always set dryer/cooler to deliver water activity average below the upper threshold by the average range.

Source: AllAboutFeed vol 1 nr 1, 2010