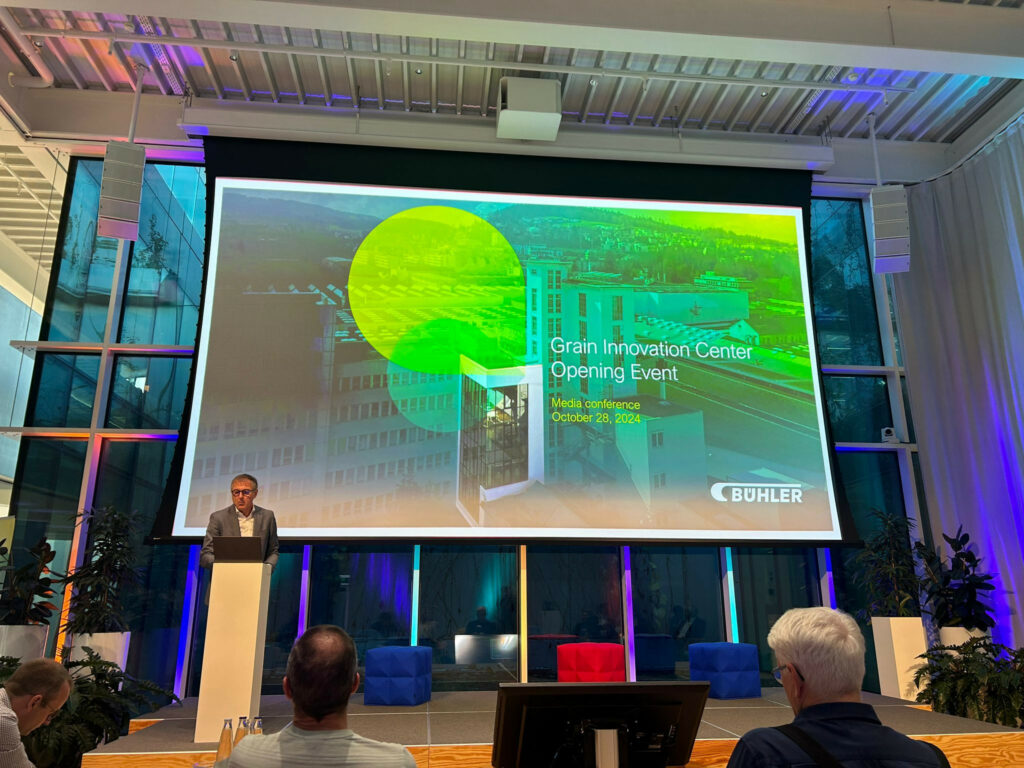

Bühler opens new facility to drive innovation and collaboration

Technology group Bühler has opened its new Grain Innovation Centre in Uzwil. The facility is designed to drive innovation and collaboration. During a visit to the centre, All About Feed spoke with key team members about the opportunities it offers and the role it plays in shaping the future of the industry.

Replacing the former Grain Technology Centre, which served the milling industry since 1951, the new 5-story, 2,000-sqm facility features state-of-the-art infrastructure and more than 70 pieces of equipment from Bühler and its partners.

The new Grain Innovation Centre offers a space for customers to test and develop new processes, which help them to succeed in an industry that is continuously evolving, explains Johannes Wick, CEO of Grains & Food at Bühler Group. “With changes in global grain supply chains, nutritional requirements, transparency of sourcing and pricing pressure, the milling industry faces a challenging environment. These include maintaining flour quality with variable raw materials, improving production and energy efficiency, managing safety issues, or finding and keeping well skilled professionals.” He continues: “Adopting new technologies – such as automation, IoT, and data analytics – and addressing environmental concerns – add complexity, while growing consumer demand for healthier and more sustainable products has driven a faster pace of innovation.”

In the new centre, which is equipped with the latest technologies for processing, it is possible to conduct tests on food and animal feed, leading to the development of new solutions in various areas that will drive innovation and help to tackle these challenges, Wick explains.

According to Gero Zimmermann, department manager Process Technology, Animal Nutrition at Bühler, the animal feed industry has significant potential to enhance efficiency while reducing its ecological footprint. Zimmerman believes this can be achieved through advanced, adaptable machinery paired with digital technologies that streamline workflows, improve decision-making processes and, in some areas, already keep processes fully automated at their most efficient point. Also, optimising the protein chain with functional additives and alternative proteins will improve animal health and minimise environmental impacts, he adds.

AI and digital tools to ease industry pains

Zimmermann underscores the transformative role of AI and digitalisation in optimising feed production. The new technologies can contribute to ease key industry pains such as fluctuating raw material quality, instable production conditions, and changing weather conditions. In addition to this, plant operators will receive more support from AI technology.

Bühler is actively using AI and other digitalisation tools to enhance their processes and products. The company has been investing in digital technologies, including AI, to improve efficiency, quality, and sustainability in their operations. These technologies are used in various aspects, such as optimising production processes, predictive maintenance, quality control, and enhancing customer service through smart solutions.

“While automation is advancing rapidly, human expertise remains critical for complex decision-making and oversight,” Zimmermann notes.

According to him, very few plants operate even partly autonomously, primarily due to the high investments required for automation and the complexity of the processes involved. In addition, machines and automated systems require regular maintenance, troubleshooting, and oversight – roles that necessitate human intervention, explains Zimmerman.

Moreover, he adds: “Ongoing research and development, process improvements, and innovative ideas are driven by human creativity, which is crucial for continuous advancement.”

We are continuously developing new methods to enhance upcycling efficiency.”

Transforming side streams into value

A key topic of discussion during the opening event of the Grain Innovation Centre was upcycling side streams from food production into valuable feed ingredients. Wick recognises the critical importance of upcycling side-streams and notes that the innovation centre plays a pivotal role in this endeavor by integrating both food and feed operations within our innovation hub.

He explains: “This allows us to explore and develop efficient methods for processing side-streams from various food processes into valuable feed products and food ingredients. We are continuously developing new methods to enhance upcycling efficiency. Key techniques include advanced separation technologies to isolate valuable components, extrusion and fermentation to transform by-products into nutritionally rich feed, and adaptive automation systems to ensure optimal processing conditions and output quality.”

Connecting food and feed

Christoph Näf, head of Business Area Value Nutrition at Bühler, highlights the Grain Innovation Centre’s role in bridging the food and feed industries. “In the Grain Innovation Centre, we have food and feed operating under one roof, right in the middle of our innovation hub with our application centres, which are all focusing on food – pasta, extruded products like cereals or plant-based meat, protein extraction, confectionery products, and more. In all these processes there are side streams that can be further processed for the food and feed industries. So yes, Bühler actively bridges and connects these industries.”

A collaborative ecosystem

Bühler’s innovation ecosystem extends beyond the Grain Innovation Centre, emphasises Wick: “Partnerships with academic institutions like École Polytechnique Fédérale de Lausanne and Feasibility Lab at the Swiss Federal Institute of Technology Zurich contribute to delivering pioneering technology and business solutions that help to meet the needs of a growing global population sustainably.”

For example, together with ETH, the company launched ‘BEXL – Bühler Exploration Lab’ in which ETH students work together with Bühler engineers to accelerate innovation and minimise risks associated with investment decisions.

A hub to test cutting-edge solutions

The overall success of Bühler’s Grain Innovation Centre can be attributed to several factors, according to Wick: “Firstly, it serves as a collaborative hub where industry experts, researchers, and customers can come together to develop and test cutting-edge solutions. This collaborative approach accelerates innovation and addresses industry challenges more effectively.”

He continues: “Moreover, companies recognise the importance of investing in innovation to improve performance, and stay competitive, especially in a rapidly changing market. As a result, investments towards R&D and innovation centres are necessary. Bühler’s Grain Innovation Centre has become a focal point for these investments, providing the infrastructure and expertise needed to drive advancements in the food and feed industry.”