Insects in pig feed in Australia

Exciting new developments are speeding up the use of Black Soldier Fly larvae meal in pigs and other livestock species as well.

In Australia, Europe, North America and other locations, Black Soldier Fly larvae meal (BSFLM, from larvae fed food waste) is making inroads as a livestock feed ingredient – and in Australia, a pilot project is underway to ensure its acceptance for hogs.

Duncan Rowland, executive officer at the Feed Ingredients & Additives Association of Australia (FIAAA) and the Stock Feed Manufacturers’ Council of Australia (SFMCA), notes that BSFLM is already also found in pelleted poultry feed in some states. Additionally, it is found in extruded feed manufactured for various fin aquaculture species, mainly Atlantic salmon, edging out more of the soybean meal or fishmeal in this feed.

At present, however, insect protein cannot be used for use in pig feed in Australia as it meets the definition of swill. According to Animal Health Australia, swill includes all meat or meat products and any food that has come in contact with meat, which are materials recognised as a significant risk factor for the introduction and spread of many diseases such as foot-and-mouth disease and African Swine Fever.

Because Black Soldier Fly larvae can potentially be fed food waste that could contain even small amounts of meal or meal products, extra precautions must be in place before it can enter the pig feed supply chain.

“If insect protein is to be used for feeding pigs, a risk assessment needs to be undertaken and agreed to by the Australian Government’s Chief Veterinary Officers,” Rowland explains. “There would also need to be some system in place that would ensure the insects being raised do not come in contact with meat products and that they [clean] out before processing. So that would be a Quality Assurance or verification system to provide proof of certain practices.” Of the various programs available, Rowland and his colleagues believe that SFMCA’s ‘FeedSafe’ effectively handles all aspects – the requirements of end-users, governments and those implementing the system.

Pilot trial with 2 insect manufacturers

SFMCA is now working, in collaboration with the Insect Protein Association of Australia (IPAA), on a pilot project with 2 insect manufacturers located in the states of Victoria and the Australian Capital Territory to trial FeedSafe in these operations. In this trial, any changes needed to the established FeedSafe program will be noted and included for review by the appropriate government personnel.

“The trial is in its early phase at these sites,” says Rowland. “We will be working as fast as the businesses want to move, so we’re looking at somewhere between 6 and 12 months to implement and document and collect data. This will require an internal audit as well as a third-party audit.”

A look at companies

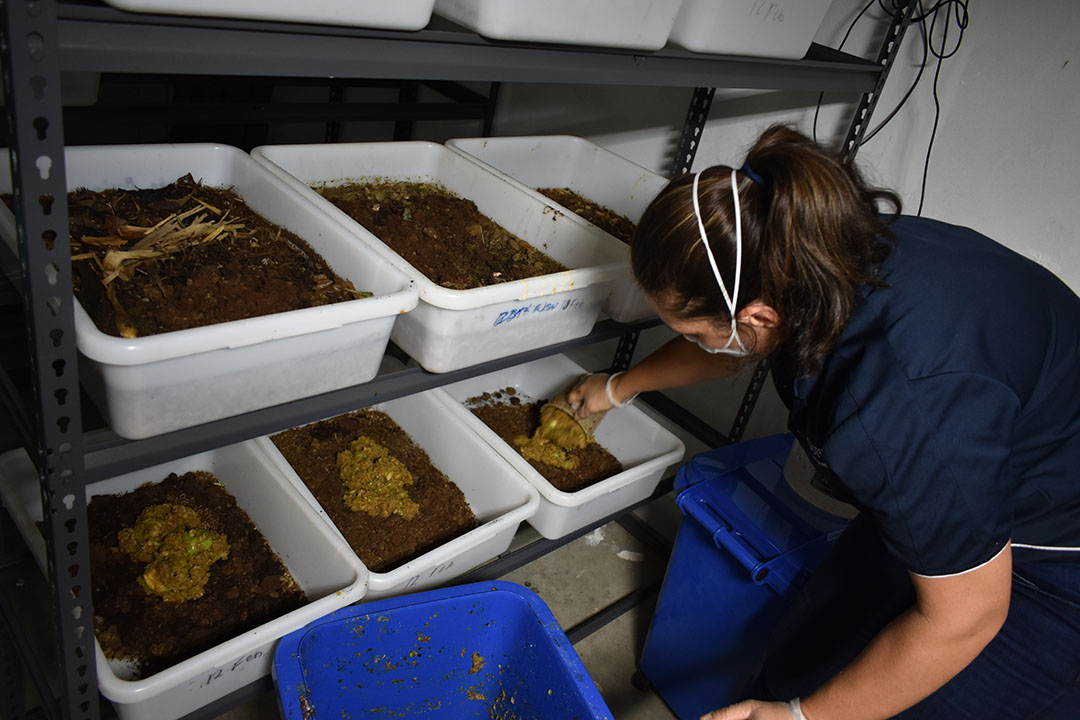

GOTERRA, Australia’s largest insect protein producer, located in Canberra, currently collects 20 tonnes of waste a week from the waste stream of homes and the waste disposal systems of high-rise buildings. Other companies that use similar sources include Mobis in South Australia and Waste Not Food Recycling in Broome, Western Australia.

Olympia Yarger, IPAA chair and GOTERRA’s founder and CEO, explains that for her firm to sell BSFLM for pigs (once the quality assurance is in place), she would have to find agricultural waste streams like fruit pulp.

Since 2017, GEA, one of the world’s largest suppliers of food processing technology, has been supporting Australia-based Future Green Solutions in carrying out research on processing BSFL into animal feed by providing expertise and a separating decanter.

InnovaFeed, ADM plan world’s largest insect protein plant

InnovaFeed, ADM plan world’s largest insect protein plant

InnovaFeed (France) and ADM (US) are planning to build the world’s largest insect protein plant in Illinois (US).

In the press release, GEA notes that the legislation around the processing of insects for both the food industry and the animal feed industry differs around the globe. “GEA chose to partner with an Australian company because the country has more flexibility when it comes to feeding the insects farm waste or waste from canteens. Right now, you cannot take the same approach in Europe, it’s much more limited because of the legal framework. However, the Australian government has given Future Green Solutions a number of grants and is interested in pushing this type of development.”