Moving towards more sustainable fish feed

Brand-new developments in sustainable ingredients, including ‘circular’ ingredients from waste and from nature.

How is aquafeed evolving to become much more sustainable and what can we expect to see in the future? Building on past advances, new innovations are being realised with oil and protein aquafeed ingredients that replace oil and meal from both fish and terrestrial crop sources. In addition, there is active investigation in many countries of highly-sustainable ‘circular’ feeds that incorporate waste of various types.

Fish oil and meal replacement

While fish oil and meal make ideal feed ingredients for many aquaculture species, especially carnivorous salmonids, replacements are needed because of sustainability concerns. To replace these ingredients, years ago the global aquafeed sector turned to oils and meals made from crops such as soybean and canola. These currently constitute 70-80% of aquafeed ingredients, according to the Institute of Marine Research (IMR) in Norway. However, oils and meals from crops create imbalances in terms of fatty acids and amino acids, along with less-than-ideal palatability and digestibility (beyond the environmental and social justice concerns with soybean production in some countries).

In terms of new protein sources, according to Rick Barrow, aquafeed consultant and retired USDA fish nutritionist, facilities to produce a cost-competitive protein concentrate from feed-grade barley are under construction in the US and Europe. Commercialisation of single-cell protein (SCP) from yeast and bacteria sources for aquafeeds, adds Barrow, has already been achieved by firms such as Calysta, KnipBio and NovoNutrients. University of Idaho scientists recently published a study showing that a commercial SCP bacteria-based product has a nutrient profile (oil, protein plus) similar to wild-capture fishmeal, but SCP had already been commercially-produced in the 1990s in Finland from forestry residues (for pig feed).

Microalgae also contain oil and protein, and it is not easy to compare them with SCP in terms of sustainability. Both SCP and microalgae production require inputs of carbon chains. The microalgae used commercially right now are ‘heterotrophic’ and not ‘autotrophic’ This means that they use light through photosynthesis to capture CO2 from the air as a carbon source. It would be a significant breakthrough, notes IMR scientist Erik-Jan Lock, to be able to use ‘autotrophic’ algae, but it’s a challenge to ensure that enough light is provided to all algal cells as they grow, since they block light from each other when densities increase. Yeast and bacteria grow much faster than microalgae and SCP is generally considered a cheaper option for large-scale oil production. Nevertheless, several companies (Veramaris, Corbion, ADM, for example) already market microalgae oil products, and Barrow says major aquafeed producers such as Cargill, Nutreco and BioMar are forming strategic partnerships with some of them.

Insect meal as feed ingredient

Many companies including Protix, Ynsect and AgriProtein have already commercialised protein and oil-rich insect meal as an aquafeed ingredient, mainly using black soldier fly larvae and mealworms. IMR reports that seven species of insects have been approved for use in the EU for salmon feed. Insect meal is highly sustainable as the insects’ diet consists of human food system waste that would otherwise go to a landfill. Indeed, insect meal production, for a variety of livestock sectors, is ramping up in Europe, North America, Australia and beyond. IMR scientists are currently examining methods of testing to ensure that the contents of insect meal product match the labelling in terms of the insect species, but more importantly, that the insects have not been fed any animal products. Feeding animal products to insects is prohibited in most places in the world, as it’s prohibited for any livestock species, in order to prevent diseases related to, for

example, prion transmission.

Seaweed as feed ingredient

Also at IMR, fermented seaweed is being investigated as an aquafeed ingredient, mostly as a functional ingredient as it only contains small amounts of protein and fat. That is, during fermentation of seaweed, Lock explains, some of the carbohydrates are broken down and formed into compounds, eventually seeming to enhance the growth of ‘good’ bacteria in the fish gut, a probiotic effect. However, there are many contradictory research results in this area so far. “In a feeding trial with salmon, we’ve included it up to 4%,” Lock says. “While it’s low in protein and fat, if it improves gut health, then it may be worthwhile as a feed ingredient. Fermentation is also a low-cost way to preserve seaweed, which is harvested once a year. However, it’s expensive to dry and grind it.”

‘Circular feeds’

The most sustainable feed ingredients are those that come from waste, as is the case with insect feed. This is an example of ‘circular’ food production. However, if the power of nature can be harnessed, a different kind of circular aquaculture can be attained. In Norway, there is the potential to cultivate far more mussels than can be absorbed by human food market, and the ‘extra’ mussels can thus be ground into meal that can be fed as a protein ingredient to farmed fish. In terms of how much protein could be provided by mussel meal, IMR benthic resources scientist Øivind Strand says there are estimates that 5000 square km of coast would be needed for 1 million tonnes of mussel production, which is less than 5% of Norway’s coast. He and other IMR scientists are using modelling to determine how increased cultivation of mussels might impact ocean ecosystems. However, they are optimistic. “The blue mussel is an excellent way to replace what’s left of fish meal in the salmon diet and also a great source of Omega fatty acids,” Strand says. “This offers a viable way to produce a protein-and-oil rich aquafeed ingredient without using more land or sea area. If we use green energy to harvest the mussels, this feed production would be even more sustainable.”

Similarly, bristle worms thrive under conditions in open-cage ocean fish farms, and like mussels, they also have a good Omega fatty acid and protein content. While they could not provide the volume that mussels could, researchers at IMR are looking into how worm populations grow, their feed conversion efficiency, potential methods of harvesting and so on. Lock and Strand explain that bristle worms grow well on objects with hard surfaces, but there are some potential harvesting challenges with these organisms in that they tend to prefer a depth of about 100 m.

Other research

Anders Kiessling, a former researcher at IMR and currently an aquaculture nutrition professor at the Norwegian University of Life Sciences, with colleague Torbjörn Lundh at the Swedish University of Agricultural Sciences, now lead a multi-national collaborative team evaluating alternative feeds that are already regulated but also some that may be approved in future. These include food waste processed by insects, forestry debris transformed by fungi, and nutrients from extractive aquaculture, such as farmed blue mussels and sea squirt. A new fermented locally-farmed fava bean concentrate is also being tested as a replacement for soybean meal. The feeds will be given to rainbow trout in experimental settings and it will also be fed at a commercial farm. They will be tested for taste and more by chefs and through feedback from one of Sweden’s largest retail and restaurant chains. The fish will also undergo metabolomic profiling using NMR technology.

Looking forward

In a paper titled ‘Thoughts for the Future of Aquaculture Nutrition,’ scientists from Australia US and Scotland note that, overall, aquafeed R&D is already focused on nutrients, but they urge an even greater emphasis, including nutrients that are not considered strictly essential, in order for the aquaculture sector to make larger advances in feed efficiency. And in a new analysis in the journal Nature, Rosamond Naylor, the William Wrigley Professor of Earth System Science at Stanford University (US) and her colleagues note that while aquaculture has made significant strides toward sustainability, more effective oversight measures are needed. They recommend, among other actions, incentives for sustainably-designed aquaculture systems, and a ‘food systems approach’ to governance that considers nutrition, equity, justice and environmental outcomes across all operations, on land and at sea.

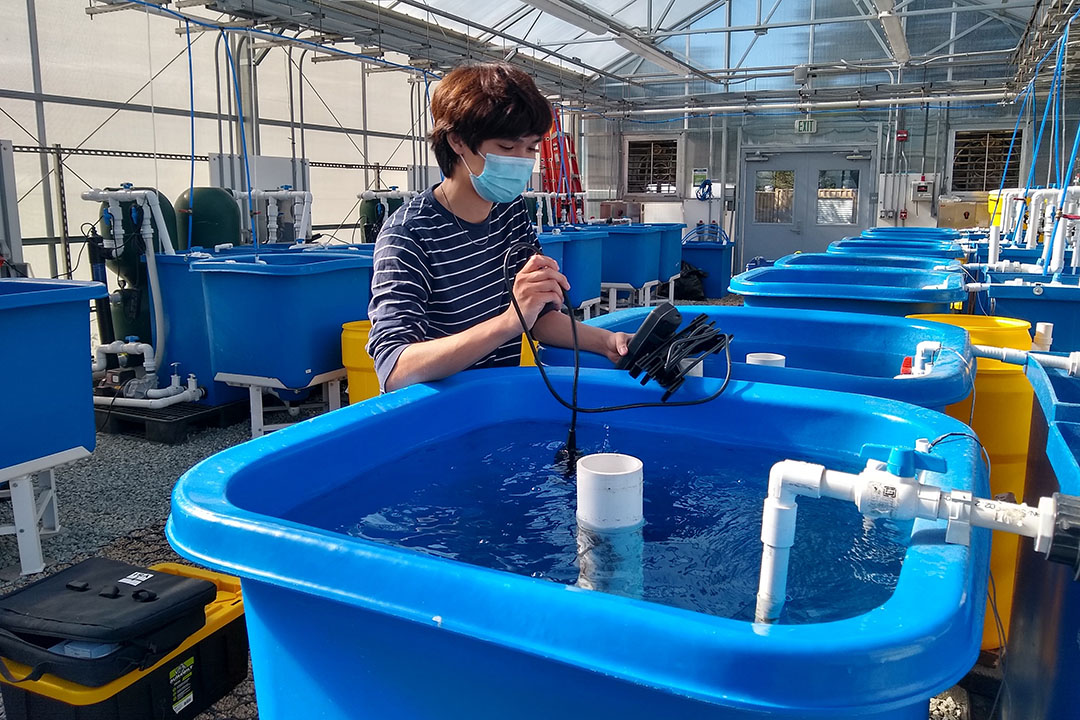

Dr Pallab Sarker and his colleagues at the University of California Santa Cruz, have recently published a paper in the journal Nature on feed for tilapia containing protein-rich defatted biomass of microalgae Nannochloropsis oculata (the oil is extracted for human dietary supplements). The feed also contains whole cells of DHA-rich microalgae Schizochytrium sp. as a substitute for fish oil. The scientists found significantly better growth, weight gain, specific growth rate and similar feed conversion ratio compared with the reference fish-oil-and-meal diet. The fish-free feed also yielded similar fillet lipid, DHA and protein content.