Boost your risk management capability with enzymes

Risk management is a hot topic and companies in most industries are assigning resources to risk management. Enzymes offer an effective tool in risk management strategies to counter raw material price volatility in the animal feed industry. With increasing prices of feed phosphates and other key raw materials, producers should consider increasing the inclusion rate of phytase in their feed, as well as maximising nutrient availability via the use of carbohydrases and other relevant enzyme activities.

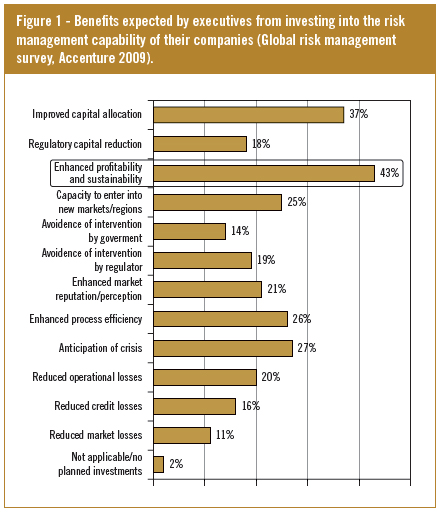

The ability to make smart decisions about what tools and technologies best support risk-management efforts could be what distinguishes high performers from the rest. A global risk management study in 2009 emphasised the fact that risk management can be a competitive differentiator, helping companies advance toward high performance. The research involved a survey of the risk management attitudes and capabilities of more than 250 of the world’s largest companies. The good news emerging from this survey is that, although executives recognise that they will need to make new investments in their risk management processes, they also expect the changes to deliver positive bottom-line results. Almost half of the respondents invest in risk management expecting enhanced profitability and sustainability as the primary benefits (Figure 1). Further studies showed that leading companies are supporting procurement with risk management capabilities to control the impact of price volatility in raw materials and are thereby able to significantly reduce raw material costs. Price volatility in raw materials was shown to be the second most important risk for procurement after dependency on critical suppliers.

Price volatility of raw materials

Price volatility in raw materials is a fact of life, taking its toll on companies that produce everything from basic materials and intermediates to components and consumer goods. The feed industry faces exactly the same challenges. The past 10 years have seen major increases in prices of the main feed ingredients used in animal diets. Corn prices have approximately doubled over this period (Figure 2) and current corn prices (Feb., 2011) have risen to around $7 per bushel in the US. In Europe, the price of wheat has jumped from €120 to €258/t over the past year. Recent press releases indicate world grain prices for wheat, corn and soybeans to rise on record short supplies and feed phosphate price is also expected to rise in 2011. Given the likelihood of continued price and supply volatility of the major feed ingredients, companies will be forced to establish core capabilities in actively managing price swings in order to remain profitable.

Price volatility in raw materials is a fact of life, taking its toll on companies that produce everything from basic materials and intermediates to components and consumer goods. The feed industry faces exactly the same challenges. The past 10 years have seen major increases in prices of the main feed ingredients used in animal diets. Corn prices have approximately doubled over this period (Figure 2) and current corn prices (Feb., 2011) have risen to around $7 per bushel in the US. In Europe, the price of wheat has jumped from €120 to €258/t over the past year. Recent press releases indicate world grain prices for wheat, corn and soybeans to rise on record short supplies and feed phosphate price is also expected to rise in 2011. Given the likelihood of continued price and supply volatility of the major feed ingredients, companies will be forced to establish core capabilities in actively managing price swings in order to remain profitable.

Mitigating price volatility

Risk management is the process of identifying, categorising, measuring, monitoring and mitigating risks in an organisation. As with any good risk management strategy, companies looking to mitigate risks associated with raw material price volatility must look up and down the value chain and consider all the risks involved. After these risks are assessed, companies can then choose from among four categories of risk transfer and mitigation techniques:

Risk management is the process of identifying, categorising, measuring, monitoring and mitigating risks in an organisation. As with any good risk management strategy, companies looking to mitigate risks associated with raw material price volatility must look up and down the value chain and consider all the risks involved. After these risks are assessed, companies can then choose from among four categories of risk transfer and mitigation techniques:

1) Upstream risk transfer to suppliers,

2) Downstream risk transfer,

3) Risk transfer to outside entities and

4) Internal risk mitigation.For internal risk mitigation of price volatility in feed raw materials, the key for producers and feed companies is to increase flexibility in feed formulations, allowing companies to switch to alternative, but cheaper raw materials. It’s a matter of being able to spread the risk of any particular feed ingredient becoming overly expensive, while being able to take advantage of alternative feedstuffs when they become available. All of these decisions have to be made without any negative impact on animal performance.

More complex diets

More complex diets are the result of replacing major feed ingredients to some extent with alternative, but cheaper raw materials. Increased complexity means diets can contain more antinutrient factors, become more fibrous, less digestible and more variable in nutrient value. This can have a negative impact on feeding value to the animal and ultimately performance. For example, corn DDGS used as an alternative raw material is potentially a good source of energy, protein and phosphorus.

More complex diets are the result of replacing major feed ingredients to some extent with alternative, but cheaper raw materials. Increased complexity means diets can contain more antinutrient factors, become more fibrous, less digestible and more variable in nutrient value. This can have a negative impact on feeding value to the animal and ultimately performance. For example, corn DDGS used as an alternative raw material is potentially a good source of energy, protein and phosphorus.

However, DDGS is a highly fibrous raw material, containing around three times more fibre than corn grain. When screening US-origin DDGS from modern ethanol plants for non-starch polysaccharide (NSP), which is the major part of dietary fibre, it was found that arabinoxylans and cellulose were the predominant NSPs with a value of 11.4% (on a dry matter basis). In addition, metabolisable energy in DDGS can be highly variable. This variability is much higher than that reported for corn and other grains. Therefore adding DDGS to animal diets can reduce the digestibility of energy and increase variability in that energy value.Other alternative raw materials used in animal diets often contain higher phytate levels (Table 1). Because of the antinutrient effects of phytate in the digestive tract of the animal, increasing dietary phytate has a large negative impact on the solubility and digestibility of dietary nutrients.

The value of feed enzymes

Fortunately, many of the factors which affect digestibility and variability in nutrient availability can be targeted by appropriate enzyme supplementation. This allows producers and feed companies to switch to alternative cheaper energy sources, without compromising animal performance. The most common feed enzyme used in animal diets is phytase, which releases phosphorus bound in phytate in raw materials. This can help to reduce dependence on supplementary inorganic phosphorus that, especially in recent years, has been highly variable in price. With current increases in feed phosphate prices, extra savings can be made by replacing dicalcium phosphate with higher levels of phytase in the diet (Figure 3), while maintaining animal performance. However, increasing levels of a highly bio-effective phytase in the diet can also help to reduce the antinutrient effect of phytate, releasing extra energy, amino acids and calcium. This offers the opportunity to switch to alternative raw materials with higher phytate levels. To be effective against phytate (IP6) as an antinutrient in the animal, phytases need a high affinity towards IP6 and to express high activity at low pH in order to break down IP6 quickly in the upper part of the digestive tract. This is critical since a low pH makes phytate more soluble and susceptible to phytase attack, whereas once phytate forms insoluble complexes with calcium lower down the digestive tract, the phytase is unable to break it down. In this respect new generation bacterial phytases have been shown to be more effective than traditional fungal phytases.

Fortunately, many of the factors which affect digestibility and variability in nutrient availability can be targeted by appropriate enzyme supplementation. This allows producers and feed companies to switch to alternative cheaper energy sources, without compromising animal performance. The most common feed enzyme used in animal diets is phytase, which releases phosphorus bound in phytate in raw materials. This can help to reduce dependence on supplementary inorganic phosphorus that, especially in recent years, has been highly variable in price. With current increases in feed phosphate prices, extra savings can be made by replacing dicalcium phosphate with higher levels of phytase in the diet (Figure 3), while maintaining animal performance. However, increasing levels of a highly bio-effective phytase in the diet can also help to reduce the antinutrient effect of phytate, releasing extra energy, amino acids and calcium. This offers the opportunity to switch to alternative raw materials with higher phytate levels. To be effective against phytate (IP6) as an antinutrient in the animal, phytases need a high affinity towards IP6 and to express high activity at low pH in order to break down IP6 quickly in the upper part of the digestive tract. This is critical since a low pH makes phytate more soluble and susceptible to phytase attack, whereas once phytate forms insoluble complexes with calcium lower down the digestive tract, the phytase is unable to break it down. In this respect new generation bacterial phytases have been shown to be more effective than traditional fungal phytases.

There is also increasing independent evidence to show that carbohydrase enzymes can offer an advantage in addition to phytase in animal diets. This is because these enzymes are able to release extra energy and amino acids. For example, xylanase breaks down arabinoxylan in cell walls to expose starch and other nutrients for digestion. Table 2 demonstrates the positive effect of adding both xylanase and phytase to pig diets containing 20% DDGS. Thus, showing the enhanced flexibility with enzymes to switch to alternative, cheaper raw materials.