Defending against spoilage – best practices to optimise silage and TMR

A dairy cow’s performance can be affected by a wide range of factors, including her dry period, the transition to lactation and exposure to heat stress. Good quality silage and a well-balanced blend of nutrients in the TMR play a crucial role in managing these challenges.

Microbial activity poses a persistent threat to silage and the total mixed ration (TMR) due to the presence of naturally occurring bacteria, yeasts and moulds. The risk can be greater during warm seasons when higher temperatures and moisture provide conditions favourable to microbial growth.

In this article, we delve into the importance of microbial control and preservation techniques, with a focus on how applying specialty feed additives can help maximise feed quality and minimise spoilage. Managing microorganisms is never a one-and-done job. Microorganisms contaminating crops in the field and during harvest can proliferate following ensiling, after opening of the silage (mainly at the cutting edge) or in the TMR once the silage is mixed into the dairy ration. Conditions favourable to the growth of harmful microbes can lead to a range of consequences that include reduced palatability, an increase in the temperature of the silage and TMR and reduced nutritional value.

The following silage management steps can help defend against harmful microbes, contribute to better quality silage and support TMR quality from pre-harvest through storage and feeding.

Manage the crop before harvesting

Manage the crop before harvesting

A few actions should be considered to reduce the risk of contamination with undesirable microorganisms. First, avoid surface application of slurry within ten weeks of mowing. Residual fertiliser increases the buffering capacity of grass, which slows down the acidification process of beneficial bacteria. Monitoring and adjusting moisture content helps promote optimal fermentation. Excess moisture can result in undesirable fermentation and spoilage, while insufficient moisture may hinder compaction and oxygen exclusion. Ensure that maize is not irrigated too much to avoid mould developing while the crop is still in the field. As maize matures and the risk of fermentation increases, maize silage should be harvested before it reaches the drought stage.

Reduce contamination and growth of undesired micro-organisms during harvest

Reduce contamination and growth of undesired micro-organisms during harvest

A well-organised harvest plan avoids a delay in filling silos, reduces soil contamination and ensures that the silage storage space is clean, the surface is smooth, and the silo does not leak before it is filled. Once these conditions are set, some good practices to aim for include:

- Apply high packing densities to help remove oxygen and facilitate fermentation.

- Pack silage in thin, uniform layers to minimise air pockets.

- Ensure that silos or bunkers are properly designed and sealed to prevent air infiltration.

Reduce undesired growth of micro-organisms during storage

Reduce undesired growth of micro-organisms during storage

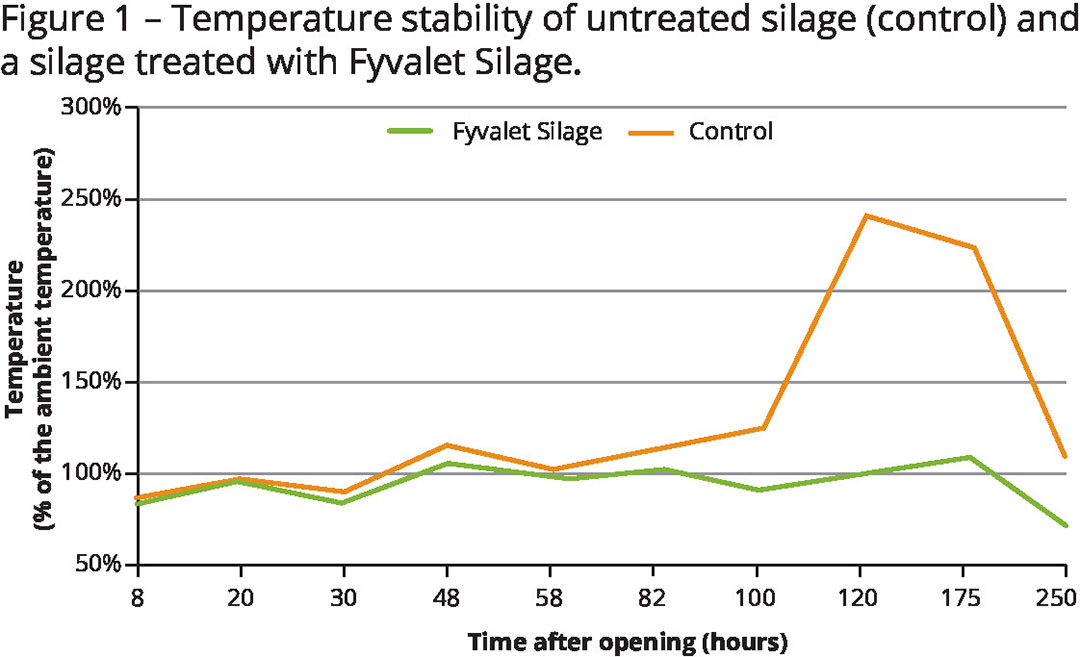

After harvesting and ensiling crops, it is important to maintain the quality of the silage during storage. Several actions can help reduce oxygen exposure and promote growth of beneficial lactic acid producing bacteria to reduce pH and inhibit spoilage by micro-organisms. Additives containing organic acids will prevent aerobic deterioration. Specific blends of organic acids act to inhibit the growth of micro-organisms that can lead to spoilage, reduce pH levels and enhance fermentation. Selko developed Fyvalet Silage to help reduce spoilage of silage by micro-organisms such as yeasts, moulds and Enterobacteriaceae during the first period of ensiling. The product improves the temperature stability of the silage, ensuring that it lasts for as long as possible after opening the clamp (Figure 1).

The use of inoculants should be considered to stimulate the growth of lactic acid forming bacteria. Silage inoculants based on lactic acid bacteria can improve aerobic stability and fermentation characteristics. Fyvalet silage is partly buffered and is therefore safe to use in combination with inoculants.

Manage silage for dairy cows at feeding

Manage silage for dairy cows at feeding

Once a pit is opened and the silage is included in the TMR, exposure to oxygen occurs and micro-organisms may start to grow again. If air leaks into the silo, growth of micro-organisms, particularly moulds, can occur at the top layer and the lateral sides of the silage. This growth of micro-organisms at the cutting edge of the silage and in the TMR should be avoided as much as possible and applying the best practices presented below can reduce silage’s exposure to air and spoilage.

Cutting the silage so that the face of the silage remains smooth keeps the surface area as small as possible, allowing less air penetration. Selko offers Selko-TMR, a potent mix of specific organic acids which can be used to treat the cutting surface, top layer and sides of the silage, slowing down fermentation and reducing the risk of microbes forming.

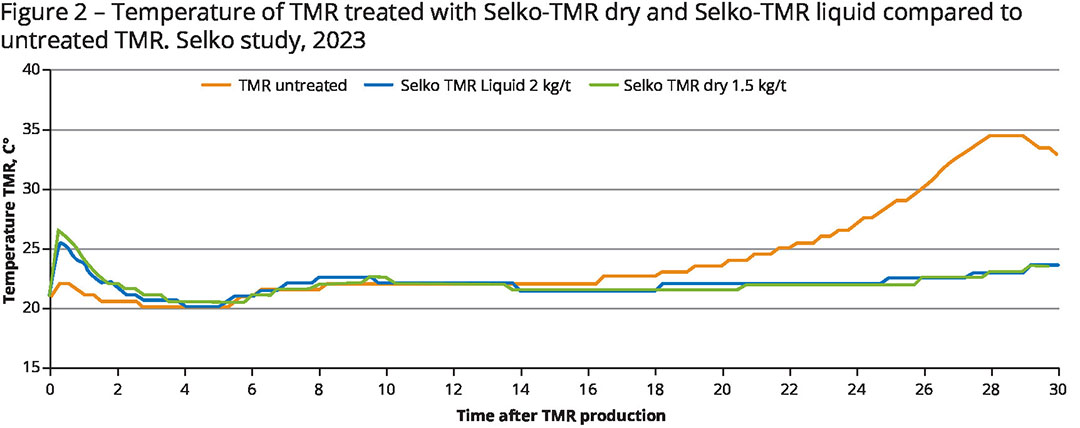

As opposed to feeding once a day, feed dairy cattle twice daily to reduce exposure of the TMR to oxygen. Mix Selko-TMR into the TMR to reduce growth of micro-organisms and keep the TMR fresh for a longer period of time (see Figure 2).

Regular monitoring and adjustments

Regular monitoring and adjustments

Regularly monitor the temperature, smell and appearance of silage to assess its quality. As part of our Feed Safety and Quality programme, Selko offers knowledge and services, such as laboratory and technical support to provide advice and guidance to maintain silage and TMR quality. Furthermore, safe and accurate dosing equipment can help ensure the best spread and most effective inclusion of Selko products.

Careful attention helps deliver consistent quality

Microbial control and preservation strategies are critical components of silage and TMR management that directly impact feed quality, animal health and farm profitability. By implementing best practices such as proper harvest timing, effective compaction, oxygen exclusion, and the use of inoculants and Selko’s specialty feed additives, farmers can optimise silage fermentation, minimise spoilage, and maximise the nutritional value of feed. Careful attention to these efforts can help livestock producers ensure consistent, high-quality feed for their animals, leading to improved performance, reduced waste and overall success in their farming operations.