Live yeast: Ensuring its viability for optimal efficacy

Over the past decades, the growing understanding of live yeasts’ mechanism and precise benefits — coupled with increased demand for natural feed additives — has led to heightened popularity for supplementing animal feed with such probiotics.

The viability of a probiotic is a key parameter to ensure its metabolic activity once ingested by the animal. Many experts insist that probiotics must be alive and viable to exert an effect on the microflora within the digestive system. Indeed, several national authorities will only authorise a claim for performance (such as improved milk production or feed efficiency) when the probiotic microorganism is viable. For example, the European Commission considers microorganisms as probiotic feed additives only in their live form.

When selecting a probiotic yeast, it is crucial to ensure the live yeast will survive feed or premix processing, tolerate the combination of other ingredients and endure storage prior to reaching the animal. Today, the increased demand for pelleted feed, with more and more stringent processes, could limit the inclusion of probiotic yeast in this form of feed. Thanks to continuous investments in process development, scientists at Lallemand Animal Nutrition have developed a patented yeast protection technology, Titan, that ensures optimal yeast survival and stability during industrial feed processing steps and feed storage.

Overcoming the stress of pelleting and storage

Like many other biological feed additives, such as vitamins or enzymes, live yeast can be sensitive to external stresses such as heat, moisture, pressure or the contact with certain chemicals or trace elements.

These factors can impact yeast viability or metabolic activity — and, therefore, its efficacy. As a result, protection can be necessary for specific probiotics to ensure their stability through the feed pelletising process and during storage. Titan technology has been developed to ensure protection of probiotic yeast throughout industrial pelleting processes and feed storage.

Specific industrial process

When producing live yeast, each and every step can impact its viability. When the process optimisation team at Lallemand worked on developing Titan, they scrutinised the whole process. They adapted the fermentation and drying processes and combined this with an extra step: a protective microencapsulation.

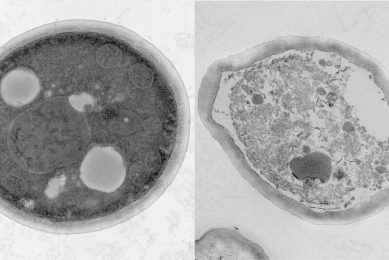

When producing Titan yeast, the fermentation and drying conditions are specific. Following fermentation, the conventional active dry yeast (ADY) process is typically extruded into a vermicelli particle form. This form of ADY is suitable for less stringent applications such as mash feed. For Titan production, the yeast particles are submitted to a particular drying process to form beadlets. The dried beadlets are then coated in a batch fluid bed with a specifically formulated lipid-based solution. This coating step, or microencapsulation, specific to ADY has been patented (EP 2099898B1). While many products on the market are described as ‘protected’ or ‘heat resistant’, Titan is a unique yeast microencapsulation technology in animal feed additives (Figure 1).

Figure 1 – Different forms of live yeast products. As seen on electron microscopic images, only Titan has a protective layer.

Resistance to feed manufacturing processes

This technology protects the live yeast against the constraints of the production process and ensures stability through storage time. It protects the live yeasts against the pelleting process (heat, pressure and humidity) as well as interaction with other chemical compounds used in feed manufacturing. This has been extensively proven in numerous trials, both from independent institutes and commercial feed manufacturers under various industrial feed mill conditions; in various countries; and in all feed types such as complete feed, mineral, and diets for ruminants, swine and poultry (Figure 2).

Figure 2 – Various trials showing the consistent capacity of Titan yeast to resist standard pelleting conditions (70 to 85°C after the die).

In certain cases, Titan was even able to resist drastic pelleting processes, thanks to its specific coating (e.g.: temperatures up to 120 °C , expender processes). In cases of drastic conditions with a high amount of constraints, a validation plan — including accurate sampling and ad hoc microbiological analysis — should be set up in feed manufacturing conditions. Moreover, an independent analysis was conducted by the independent institute IFF in Germany to compare the stability and the resistance of Levucell Titan live yeast to other commercial yeast sources under different pelleting conditions. This study shows that only Titan live yeast remains stable throughout the various pelleting processes (at least 85°C) (Figure 3).

Figure 3 – Pelleting stability of different yeast sources & technology (85°C).

Shelf life

Probiotic stability is not only about feed processing, it is also about feed storage conditions and shelf life. Once probiotics are included in the feed, the products must survive storage time at the feed mill and farm up until it is consumed by the animal. Trials have shown that Titan technology allows yeasts to remain stable in the feed through standard storage period.

Finally, stability and availability also is important at the end of the chain — just prior to feed consumption. The lipid-based protective coating of Titan is solubilised in the host’s digestive tract, releasing the living, active yeast in the gut to interact with and benefit the host.

How to count live yeast: The Colony-Forming Unit (CFU)

The measurement of the active yeast concentration in feed is most commonly expressed in colony-forming units (CFU) per gram, which represents the number of live yeast cells that are able to reproduce per gram of feed sample.

In practice, it is a plate-counting technique based on counting yeast colonies growing on a Petri plate provided a selective medium (or nutrients for growth and antibiotics to inhibit bacterial growth). Each colony represents the reproduction of a live yeast cell for a given duration. The results are expressed in Log10 to account for the dilution procedure applied in the lab. The CFU method is the official control method recognised by most authorities.

How to use Titan technology?

Titan technology is available to both probiotic yeast strains produced by Lallemand Animal Nutrition for both ruminants and monogastrics:

- Saccharomyces cerevisiae boulardii CNCM I-1079 live yeast, sold under trade name Levucell SB for monogastrics

- S. cerevisiae CNCM I-1077, rumen specific live yeast, sold under trade name Levucell SC

Lallemand Animal Nutrition is committed to controlling performance of its product in its customers or end-users feed facilities thanks to a dedicated technical support and lab analyses services. The company offers technical support and dedicated analyses services to make sure that Titan technology perfectly matches with industry conditions.