Modern xylanases show greater versatility

While xylanase enzymes have been available for a long time and experienced nutritionists routinely use them in pig and poultry diets, this does not mean that development of these types of products has stopped. Xylanase feed products were originally developed to be applied to wheat based diets, often with the specific aim of reducing viscosity problems caused by highly viscous wheat varieties. Now their reach is much further.

The first generation xylanase products worked reasonably well for the purpose of reducing viscosity in barley or wheat based diets, but occasionally showed weaknesses in terms of thermostability and assayability. Econase XT (from AB Vista) was developed to combine confidence in assayability with excellent thermostability, as well as superior performance in the animal. Whilst the initial application of NSP enzymes was in viscous (barley and wheat based) rations, modern xylanases like Econase XT also show excellent efficacy in corn based diets, extending their cost-effective use to most of the world.

The original trials dataset for Econase XT showed good performance in assayability, thermostability and performance, but some areas remained unmeasured. One of these was how well the product performed in terms of maintaining litter quality. The second concerned how the predicted better performance potential compared to other products, and was this improvement in performance sustained when applied to diets typical for various markets. In response to these demands from the market, additional research was initiated.

Intrinsic thermostability

Stability tests were performed using various conditioning and pelleting processes in a range of feed mills across Europe. All showed that the initial pilot-scale dataset can also be applied in commercial facilities, with typical recoveries in practical feed mills of 90-110% of the level observed in the mash. In the most extreme situation, one particular system with a long term high heat conditioner used for decontaminating feed for broiler (grand)parent stock, the lowest recovery (measured as the assayed level of activity in the pellets against the assayed activity level in cold meal) was 82%.

Given that the assayed level in the cold meal also includes background activity, which is probably less heat stable than the added product and could account for 10-20% of the added activity, this shows that Econase XT is highly stable through the pelleting process. Routine analysis of customer finished feeds confirms this, with recoveries normally seen at least at the declared level, and with low variability, confirming the mixability and assayability of the product.

Stability tests were performed using various conditioning and pelleting processes in a range of feed mills across Europe. All showed that the initial pilot-scale dataset can also be applied in commercial facilities, with typical recoveries in practical feed mills of 90-110% of the level observed in the mash. In the most extreme situation, one particular system with a long term high heat conditioner used for decontaminating feed for broiler (grand)parent stock, the lowest recovery (measured as the assayed level of activity in the pellets against the assayed activity level in cold meal) was 82%.

Given that the assayed level in the cold meal also includes background activity, which is probably less heat stable than the added product and could account for 10-20% of the added activity, this shows that Econase XT is highly stable through the pelleting process. Routine analysis of customer finished feeds confirms this, with recoveries normally seen at least at the declared level, and with low variability, confirming the mixability and assayability of the product.

Efficient matrix values

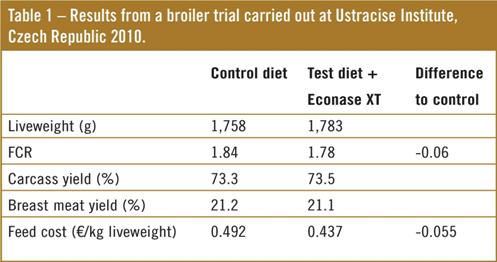

A trial was commissioned to see whether the use of the full matrix value of Econase XT to reformulate a lower cost diet would result in an equivalent broiler performance. This was performed at the Ustracise Institute, Czech Republic in 2010. A standard control diet (50% wheat, with corn and soya) was compared to a diet including Econase XT but reduced in energy (0.6 MJ) and amino acids as for the matrix was suggested by AB Vista. For amino acids this means a contribution from the enzyme equivalent to 15% of the undigested amino acids. The diet cost (excluding the cost of the enzyme) was reduced by 7.2% in the starter, 8.0% in the grower and 8.3% in the finisher diets, showing a very worthwhile return on investment provided equal performance could be reached.

A trial was commissioned to see whether the use of the full matrix value of Econase XT to reformulate a lower cost diet would result in an equivalent broiler performance. This was performed at the Ustracise Institute, Czech Republic in 2010. A standard control diet (50% wheat, with corn and soya) was compared to a diet including Econase XT but reduced in energy (0.6 MJ) and amino acids as for the matrix was suggested by AB Vista. For amino acids this means a contribution from the enzyme equivalent to 15% of the undigested amino acids. The diet cost (excluding the cost of the enzyme) was reduced by 7.2% in the starter, 8.0% in the grower and 8.3% in the finisher diets, showing a very worthwhile return on investment provided equal performance could be reached.

At the end of the trial (35 days), the birds were weighed, Feed Conversion Ratio (FCR) determined and carcass yield and breast meat yield were measured. The results can be seen in Table 1. Whilst none of these differences were statistically significant, it can be stated that use of Econase XT with its full matrix value in a diet with less energy and amino acids delivered at least equivalent performance to the control diet. Calculation of feed cost per kg liveweight produced shows a substantial reduction (-11%) in cost, as expected.

Litter quality comparison

To satisfy the requirement for information on performance in relation to litter quality and relative to competitor products, a trial was commissioned with Schothorst Feed Research in Lelystad, the Netherlands. In this trial, Econase XT was compared to three competitor products and a control diet with no xylanase included. The diet was wheat based, but with 10% rye to mimic the use of a high viscosity wheat. All diets contained phytase (Quantum) at 500 FTU/kg, similar to the normal commercial situation. The inclusion of a second enzyme (in this case a phytase enzyme) when NSP enzymes are being compared should be treated with caution as there are positive and negative factors surrounding enzyme additivity. On one hand, the presence of a phytase can reduce the potential benefits of using a xylanase since both enzymes show benefits in terms of improving amino acid digestibility and giving an energy contribution, and it should be realised that these benefits are not completely additive. On the other hand, if a strong xylanase is used in the diet, it will attack insoluble arabinoxylans in the cell wall liberating more phytate. This additional free phytate could have a negative effect in the bird unless a highly active phytase is present. The competitor products were selected based on presence in the market and product image, the first one (Product R) being a multi-enzyme complex obtained from fermentation of Penicillium funiculosum; the second (Product D) was an endo-1,4–xylanase (EC 3.2.1.8) produced by submerged fermentation of the genetically modified micro-organism Trichoderma reesei whilst the third (Product B) was a preparation of endo-1,4–xylanase produced by Bacillus subtilis. All of the products used in the trial claim they can be used in pelleted feed as they survive high processing temperatures, but this trial was not assessing stability so all diets were pelleted at a temperature below 75SDgrC.

To satisfy the requirement for information on performance in relation to litter quality and relative to competitor products, a trial was commissioned with Schothorst Feed Research in Lelystad, the Netherlands. In this trial, Econase XT was compared to three competitor products and a control diet with no xylanase included. The diet was wheat based, but with 10% rye to mimic the use of a high viscosity wheat. All diets contained phytase (Quantum) at 500 FTU/kg, similar to the normal commercial situation. The inclusion of a second enzyme (in this case a phytase enzyme) when NSP enzymes are being compared should be treated with caution as there are positive and negative factors surrounding enzyme additivity. On one hand, the presence of a phytase can reduce the potential benefits of using a xylanase since both enzymes show benefits in terms of improving amino acid digestibility and giving an energy contribution, and it should be realised that these benefits are not completely additive. On the other hand, if a strong xylanase is used in the diet, it will attack insoluble arabinoxylans in the cell wall liberating more phytate. This additional free phytate could have a negative effect in the bird unless a highly active phytase is present. The competitor products were selected based on presence in the market and product image, the first one (Product R) being a multi-enzyme complex obtained from fermentation of Penicillium funiculosum; the second (Product D) was an endo-1,4–xylanase (EC 3.2.1.8) produced by submerged fermentation of the genetically modified micro-organism Trichoderma reesei whilst the third (Product B) was a preparation of endo-1,4–xylanase produced by Bacillus subtilis. All of the products used in the trial claim they can be used in pelleted feed as they survive high processing temperatures, but this trial was not assessing stability so all diets were pelleted at a temperature below 75SDgrC.

In vivo viscosity (Figure 1), measured in two birds per pen at 22 days of age, showed that Product B did not affect viscosity at all, whilst the three other products gave a significant reduction. Econase XT gave the best numerical value of all the products in the trial. This demonstrates the ability of Econase XT to reduce viscosity in a moderately high viscosity diet, which is important if viscosity is causing reduced performance and litter quality problems.

At 42 days of age there were no significant differences in bodyweight between any of the treatments, all birds grew very well: the average weight for the male birds was 3,490 g at 42 days. There was a significant effect of enzyme treatment on feed conversion ratio (FCR). The FCR of the control diet was 1.747, and all enzymes gave a significant improvement relative to the control. Econase XT gave a significantly better FCR (1.666) than products D (1.703) and B (1.708). Product R gave an intermediate FCR. Interestingly, the FCR measured during the different feeding phases shows that in the starter and grower diets, all four enzyme products performed similarly, but Figure 2 shows that during the finisher phase Econase XT clearly gave the best performance. This indicates that, in addition to the viscosity reducing effect, Econase XT does more in terms of nutrient release than the other products.

Litter quality was based on a scale of 0-10 with 10 being excellent. At 22 days all enzymes showed an average improvement of 0.7 points relative to the control. But at 35 days, Product B showed no improvement relative to the control whilst the other three products resulted in a significant improvement of approximately 0.8. The photo in Figure 3 shows a clear difference in litter condition between the control and Econase XT diets at 22 days of age; and this differential was maintained until the end of the trial. Litter quality is a very important parameter for European conditions, especially with the Broiler Welfare regulations in force. One result of poor litter quality could be an increase in pododermatitis which is one of the parameters for judging broiler welfare standards. Even though pododermatitis is difficult to judge reliably in live birds, it was shown in this trial that Econase XT, Product R and Product D at 42 days all gave significantly fewer occurrences of pododermatitis than the control diet, with Product B being intermediate but not significantly better than the control.

Conclusion

These new trials add significant additional information to the dataset available for Econase XT, giving nutritionists the opportunity and confidence to make informed decisions about their NSP enzyme inclusion. Econase XT delivers a combination of excellent thermostability with reliable assayability as well as improved animal performance. This means that the product is easy to detect in-feed, affording peace of mind for both nutritionists and feed customers. The new data confirms that Econase XT delivers more than competitor products in terms of FCR and energy contribution in the animal, which translates to more value for the customer. The benefits in terms of litter quality had not been previously shown, simply because litter quality had not been measured. But it has now been proven that Econase XT delivers the same litter quality improvements as the best competitor products tested. Overall, it has been shown that the original strapline for Econase XT (stable and able) is very valid.

These new trials add significant additional information to the dataset available for Econase XT, giving nutritionists the opportunity and confidence to make informed decisions about their NSP enzyme inclusion. Econase XT delivers a combination of excellent thermostability with reliable assayability as well as improved animal performance. This means that the product is easy to detect in-feed, affording peace of mind for both nutritionists and feed customers. The new data confirms that Econase XT delivers more than competitor products in terms of FCR and energy contribution in the animal, which translates to more value for the customer. The benefits in terms of litter quality had not been previously shown, simply because litter quality had not been measured. But it has now been proven that Econase XT delivers the same litter quality improvements as the best competitor products tested. Overall, it has been shown that the original strapline for Econase XT (stable and able) is very valid.