Protecting phytogenics by microencapsulation

Plant extracts and essential oils have positive effects on animal health, but are often difficult to process in the animal feed. Biomin has developed an encapsulation process which overcomes these handling problems and which also gives better performance of the phytogenics in the animal.

Since ancient times, medicinal plants have been used to treat humans and livestock. The preparations made from plants were either from raw materials (leaves, roots or branches) or processed (cooked or boiled). Most likely, natural medicine has been evaluated in two directions; the first is based on observing animals’ self-medication, whereas the second is associated with human folk medicine. Nowadays the industrialised medicaments may also be plant derivatives. After decades of intensive growth promoter application, the resistance of important pathogens of farm animals to drugs has to be considered a serious threat to the profitability and consequently sustainability of animal production systems worldwide. Besides the growing problem of drug resistance amongst diseases, consumer concerns in regard to the use of chemicals in agriculture and residues in food items are also contributing to the increasing requirement for alternative measures to the exclusive use of growth promoters. The rapid growth of the popularity of organic farming can also be considered another major driving factor for the increased necessity of alternative control measures. Among the alternatives, plant extracts and essential oils also called phytogenics, have received greater attention in recent years.

Phytogenics

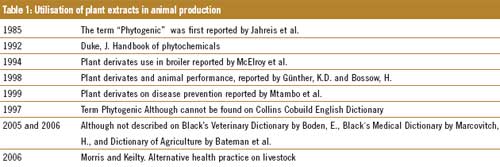

Phytogenics are plant derivate products used as additives in animal feed; Table 1 shows briefly the timeline of plant derivates used in animal feed. Returning back to what nature has so ideally provided, the studies of Amorozo (2002) indicated that there is a growing academic interest in natural pharmacopoeia which was enlarged after its ascertainment developed over centuries, moreover, nowadays having scientific proof to completely enable the usage in the industrialised society.

The mode of action of phytogenics to achieve better performance is not completely clear but according to Ultee et al (2002) and Xu et al (2008) essential oils have the ability to disrupt cytoplasm membrane of pathogens. Moreover, antibacterial activity occurs in reason of active substances of essential oils which might cross the cell membrane and interact or disrupt intracellular structures (Cristani et al. 2007). The best assumption for the performance enhancer effects is due to its antibacterial properties as mentioned above, where the reduction of pathogens within the intestines will promote less nutrient competition and consequently increase more nutrient availability for animal utilisation and also prevent intestinal diseases.In animals, the beneficial effects of essential oils supplementation include an increase of production and secretion of endogenous digestive enzymes; modulation of the immune system; antibacterial, antifungal, and antiviral activity; and decreased mortality (Cowan 1999, çabuk et al., 2006).

Under different storage conditions and environmental variations, natural products can degrade rapidly when compared to chemotherapeutics. Biomin aimed to protect phytogenic products and their benefits towards animal production and performance.

Microencapsulation

Microencapsulation is a procedure where a liquid, gaseous or solid substance is packed by a tiny millimetric capsule. In other words it is a technology of protecting a certain substance (core) into a sealed (coated, walled or shelled) capsule. The encapsulation process was discovered accidentally in the 1950s when Barret Green of the National Cash Register Company attempted to create a carbonless copy paper that would provide multiple copies.

The pharmaceutical industry later improved the encapsulation methods to safeguard, control the release and target the delivery of medicaments. The improvements developed allowed choosing the location where the drug needs to be applied and, moreover, release it at gradual or continuous rates in response to a variety of triggers. Following this tendency, the food industry emphasised on the microencapsulation of flavours to concentrate and prevent flavour losses during processing. It also established constant research to evaluate new materials and methods of encapsulation to avoid degradative reactions followed by loss of feed quality. Moreover, ongoing research has been done to reduce the capsule size to “nano” to improve its efficiency.

Encapsulation also facilitates to aggregate incompatible substances in a formulation. This can be as forthright as formulating lipophilic ingredients into clear aqueous systems. In the feed industry, encapsulation may have the following benefits:

• Flavour optimisation;

• Better handling;

• Delayed release;

• Reduce dustiness;

• Increase stability.

Phytogenic compounds such as essential oils (EO) are sensitive substances which have a tendency to lose their efficacy and efficiency in reason of quality mitigation due to their susceptibility to high temperatures, dusty inclination and remarkable odour, oxidative and volatile properties. In the course of ongoing research and innovation, Biomin “trapped” its phytogenic feed additive into a capsule by a modern matrix-encapsulation process to obtain all the benefits shown by previous encapsulation techniques, also avoiding ingredient losses during feed processing (pelletisation or extrusion) and storage.

For example, when using an extruder four different processing zones can be defined: feeding, melting, dispersion and compression. Using the microencapsulation process to protect the phytogenic product the following advantages can be obtained:

- Highly increased product value due to tailor-made encapsulation process.

- Even dispersion of essential oils in the matrix.

- Continuous EO release in the GI-tract as key to performance enhancement vs. conventional coating with punctual EO release.

- Partly masking of strong odour of essential oils and increased shelf-life.

- Better technological properties: dust free, excellent flow ability, easy to dose.

Carbohydrate carrier

The carrier is a blend of carbohydrates which are processed in a double screwed/co-rotating extruder to form the matrix capsule. The process exceeds temperatures above 100oC for a couple of seconds when the essential oils are sprayed into the matrix and sequenced by the die to cutting and forming the matrix-encapsulated P.E.P. product (Figure 1).

This contemporary method of encapsulating essential oils ensures uniform capsules with a well-defined diameter to enhance the ingredient bioavailability and efficacy. The approach of encapsulating essential oils led to the new generation of phytogenic feed additives, named Biomin P.E.P. MGE. This new innovation was developed to overcome two major technical issues with powdered essential oil additives: stability and odour. Furthermore, in contrast to conventional wax or fat coated products, the active ingredients are evenly distributed in a matrix and continuously released in the digestive tract.

Verification of its benefits

The zootechnical performance of 90 piglets was evaluated over 56 days in the experimental facilities of the Biomin Centre of Applied Animal Nutrition. This performance trial compared the addition of matrix-encapsulated essential oils (Biomin P.E.P. MGE) with conventionally encapsulated essential oils and a control group (no essential oils). Growth rate and feed conversion were positively affected by supplementation with matrix-encapsulated essential oils. Pigs fed P.E.P. MGE had enhanced weight gain (+4.9% vs. control group) and improved feed conversion (-4.3% vs. control group) as compared with the other treatments, indicating the advantages of this encapsulation technique (Figure 2 and 3).

Conclusion

The strategic and innovative encapsulation process is a new benefit which enables essential oils to have a longer shelf-life by protecting from environmental impacts, partly masking strong odour whilst maintaining key features of enhancement of palatability, stability in ration, improved digestion and, consequently, better performance.

References available upon request from marco.sousa@biomin.net