Recovery of phosphorus: Extraction from sewage sludge for feed

Phosphorus (P) mineral supplements are often provided to livestock. However, because of the EU’s import dependency and the environmental concerns with mining P, the industry is looking for alternatives for P recovery.

It’s the second most-abundant element in the animal body after calcium, with 80% of P found in the bones and teeth. The skeletal tissue undergoes a continuous process of absorption and release of Ca and P, especially during pregnancy and lactation in mammals, and during the laying period in poultry. P is also essential in maintenance of osmotic pressure and acid-base balance, cell energy utilisation and transfer, protein synthesis, transport of fatty acids, amino acid exchange and cell growth and differentiation.

the European feed industry is keenly aware that P from rock phosphate is a finite resource

Most P in livestock diets comes from grass and crop ingredients but to optimise productivity, mineral P supplements are often provided. These are derived from mined phosphate rock, and in Europe, the vast majority of this (90%) is imported. However, as Pedro Cordero (President of the European Feed Manufacturers’ Federation, FEFAC) explains, “the European feed industry is keenly aware that P from rock phosphate is a finite resource, and due to the import reliance on a few producer countries, there are also geopolitical risks. The EU in fact has recognised phosphates as a critical raw material, therefore we support all efforts that aim to reduce strategic import dependencies.”

Mining P requires large amounts of energy

In addition, mining P – as well as processing it into a useable form for livestock – requires large amounts of energy and other resources. So, recovering P from other materials rather than mining it in virgin form would likely be better for the environment and also create more supply stability, although it may not be cheaper.

Recovery efforts for P and nutrients in Europe are promoted by the European Sustainable Phosphorus Platform (ESPP), a non-profit association based in Belgium. The Platform’s ‘Catalogue of Nutrient Recovery Technologies’ lists about 40 companies with nutrient recovery processes that are already operational or have been demonstrated at full-scale or pilot scale.

Sewage sludge ash

A promising alternative to mining P starts with the ash resulting from incineration of municipal sewage sludge. Switzerland, Germany and Austria all now have regulations which will compel recovery of P from sewage sludge, explains ESPP Coordinator Chris Thornton. “Sewage sludge ash is not suitable as a fertiliser,” he says, “because the P in it is not readily available to crops. Sewage sludge ash also tends to concentrate heavy metals.”

FEFAC welcomes policy proposals by the ESPP for the use of recycled P from sewage sludge in feed, as it’s based on science and subject to safety considerations. “When it can be done safely, using recycled P in feed would further demonstrate the capacities of our sector to upgrade nutrients,” says Cordero, “and thereby contribute to the circular economy.”

Example process

Thorton explains that there are several companies that have found success recovering phosphoric acid or phosphate chemicals from sewage sludge ash, with processes that are operational or in active development. From these, feed-available or crop-available P products can be produced, he notes, but “because of regulatory obstacles in Europe, these companies are currently generally not looking to produce recycled P for animal feed.”

The European Commission has mandated EFSA (European Food Safety Agency) for an Opinion on the safety of sewage sludge ash use in fertilisers. ESPP hopes that a positive Opinion could pave the way for considering also use of purified phosphates in animal feeds.

There is one company forging a path already, however. EasyMining Services in Uppsala, Sweden has developed ‘Ash2Phos,’ a process that transforms sludge ash into a raw material for P extraction.

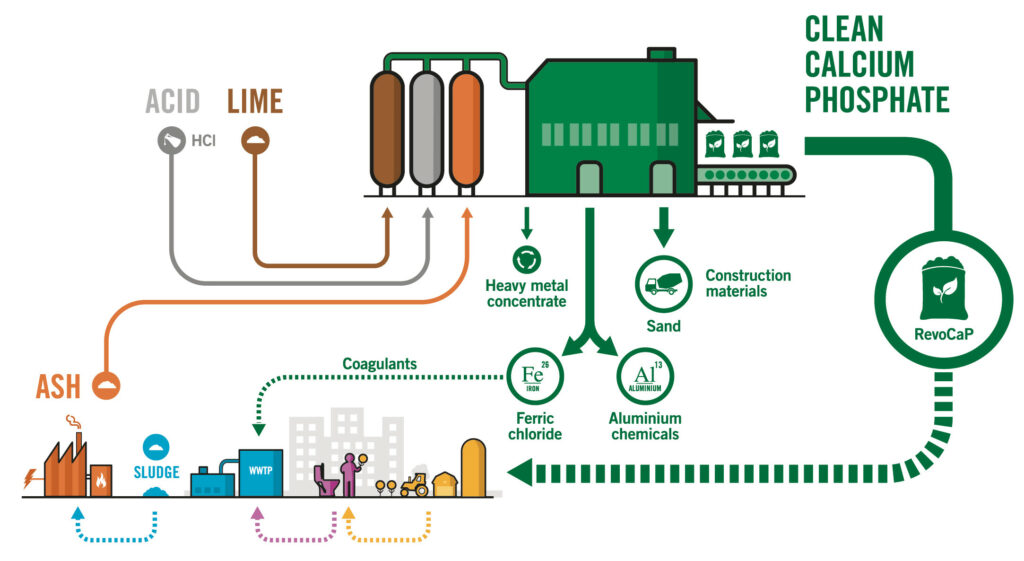

Figure – The company EasyMining Services has developed a process that transforms sludge ash into a raw material for P extraction.

(Figure) There are 3 steps in the process, explains Product Manager Dr Sara Stiernström. The ash is first subjected to an initial treatment with hydrochloric acid, then an alkaline treatment with lime. The resulting intermediate products are then converted in the final step into final products. These successive chemical reactions “separate elements of interest and detoxify the products,” explains Stiernström, while “most input chemicals become part of the products.”

From the Ash2Phos process, P is extracted and converted into what the company calls RevoCaP, a pure, non-crystalline calcium phosphate that can be added to livestock feed. Overall, the P extraction rate from sludge ash exceeds 90%. The Ash2Phos process also recovers other valuable co-products besides Ca and P, including ferric chloride, sodium aluminate and sand.

Our findings show that this recycled feed P is highly digestible for animals such as pigs and chickens and meets all quality requirements set by feed legislation

Feed trials

To assess RevoCaP’s viability in feed, EasyMining has initiated several collaborative projects with scientists at Swedish University of Agricultural Sciences and feed company Lantmännen, reports Stiernström. ”Our findings show that this recycled feed P is highly digestible for animals such as pigs and chickens and meets all quality requirements set by feed legislation.”

The 2 main pig and broiler chicken studies show that the RevoCaP has a digestibility that is slightly lower than MCP, but Stiernström says it’s in the same range as other feed phosphates. The studies compared feeds containing RevoCaP or the commonly-used monocalcium phosphate (MCP). In both studies, growth for all animals was as expected and showed no noticeable difference on any of the diets. For the pigs, the estimated total tract apparent digestibility of P in the RevoCaP was 60.4% and 83.8% of the phosphorus in MCP. For the chickens, the estimated ileal digestibility of P in RevoCaP was 58.4% and 75.1% in MCP.

EasyMining also recently launched a new research project in collaboration with Aarhus University and the Danish feed company DLG on newly-weaned pigs. Dr Tina Skau Nielsen, Associate Professor at Aarhus University, stated that “we will study how well weaned pigs can digest and utilise the P present in the recycled feed P by transitioning them from a standard diet to one of four diets: a basal diet without added P, or the basal diet with recycled feed P, MCP or di-calcium phosphate.”

Risk assessment

Stiernström also explains that EasyMining has thoroughly assessed the entire value chain – from sewage sludge to finished feed P – to ensure it’s free from relevant pathogens, including prions.

In this, EasyMining collaborated with the Swedish National Veterinary Institute

and Lantmännen to conduct a full risk assessment. It was concluded that that found calcium phosphates recovered from sewage sludge incineration ashes could be safely and effectively used in animal feed if regulatory obstacles were lifted.

Main challenges: Recycled P in feed

On the subject of these obstacles, Stiernström notes that European legislation currently prohibits (under Regulation 767/2009) feed additives or raw materials for feed to be derived from manure, or from municipal or industrial wastewater, even after incineration at high temperatures, intensive chemical processing and purification.

“Irrespective of quality and safety, such chemicals are currently excluded from use in feed,” she explains, “which constitutes an unnecessary obstacle to the nutrient circular economy. However, the Canadian legislation is different and not closed. Here we can apply to get the RevoCaP approved. We have an ongoing study this summer to investigate the potential in Canada for Ash2Phos plants.”

Their feed company collaborator in Canada for exploring recycled P in livestock feed is Friesen Company, which announced in November plans to develop feeds with imported RevoCaP.

Legislative change

EasyMining also points to a requirement for legislation promoting wastewater treatment plants to be classified as ‘resource plants’ instead – focusing on the immense value of the materials being processed in these facilities once recovered for safe use.

“We need requirements for obligatory P recovery from the plants into usable recycled products,” Stiernström explains. “For feed, it would be good with incentives not only to focus on price but also sustainability parameters.”

Facilities to come

EasyMining already has 2 Ashe2Phos plants planned with more to come, one in Germany (Ash2Phos plant Schkopau) and 1 in Sweden (in Helsingborg). They both have the capacity to process 30,000 tons of sewage sludge ash per year, equivalent to 10% of Germany’s current sewage sludge ash volume.

In the end, both plants will produce about 15,000 tons of RevoCaP (about 2600 tons of P) each year. The plant in Germany is planned to start up by end of 2026 and the one in Sweden by 2028.

Supply of sludge ash for the plant in Germany was secured in March. MSE Mobile Schlammentwässerung and Phosphorgewinnung Schkopau (a joint venture company of GELSENWASSER and EasyMining) signed a multi-year delivery contract for ash that will originate from the southwest part of the country.