Using microencapsulation to improve gut health and feed efficiency

The poultry industry is evolving to meet the demands for sustainable practices and antibiotic-free products. Microencapsulation technology offers a promising avenue for delivering alternative compounds that support gut health and improve feed efficiency.

Since the mid-20th century, the poultry industry has made significant strides in areas such as nutrition, genetics, veterinary medicine and management, resulting in improved feed efficiency, growth performance and meat yield. Recently, there has been growing concern about the environmental impact and food safety implications of animal agriculture. Consumers are increasingly demanding “clean labels” and are willing to pay more for meats that are free of antibiotic residues and raised in disease-free environments.

In response, the poultry industry and allied sectors have reduced or eliminated the use of medicated feeds. Alternative compounds with purported antimicrobial properties, such as organic acids, minerals, botanicals and essential oils, have been explored as replacements in poultry diets to reduce microbial loads in the gut.

The promise of targeted-release alternatives

Most alternative compounds, such as organic acids, minerals, botanicals and essential oils, either alone or in combination, do not directly reduce overall microbial loads in the gut in the same way as antibiotics. Instead, they modulate the gut microflora profile by inhibiting unfavourable bacteria while promoting the fermentation of more favourable species. This promotes gut health through other mechanisms, such as altering gut pH, maintaining protective gut mucins, selecting for beneficial intestinal organisms, enhancing fermentation acids, improving nutrient uptake and boosting humoral immune responses.

Essential oils, long recognised for their antimicrobial activity, have attracted particular attention due to the emergence of antibiotic-resistant bacteria. Produced as secondary metabolites from various plant parts, essential oils represent a promising alternative for livestock production. Research has shown their efficacy in reducing foodborne pathogens and studies on their mode of action have shed light on their ability to counter antimicrobial resistance and pathogenicity. Strategic use of essential oils can optimise growth if they are used in a manner that complement their modes of action.

Organic acids are also used to reduce the pH in the small intestine of simple-stomach animals such as pigs and poultry and provide greater resistance to pathogenic bacterial infections. Besides antimicrobial function, organic acids and their salts have a beneficial effect on digestibility, nutrient resorption and the performance of weaned and growing piglets.

Mode of action and benefits

Antimicrobial effects can be explained by two mechanisms. First, by pH falling below 6 in the stomach, which inhibits the growth of pathogenic microorganisms such as coliforms, and secondly, the ability of organic acids to penetrate in their non-dissociated form through the bacterial wall and destroy some specific micro-organisms. Bactericidal or bacteriostatic effects of organic acids consist above all in a direct effect of the organic acid anions on bacterial cell walls. For organic acids to function as an effective bacteriostat they must be delivered and dissociate in the large intestine where most harmful bacteria such as E.coli reside. They cannot be released in the small intestine alone.

The benefits of using acidic modifiers and organic acids for poultry, however, may be less conclusive. Dietary acidifiers may work better in baby pig diets because they have more limited hydrochloric acid production than chicks. Moreover, dietary organic acids are quickly neutralised in the duodenum unless they are delivered to the ileum and below by adsorbent vehicles. Commercial preparations of slow-release microencapsulated blends of organic acids and slow-release mineral compounds that deliver these non-medicated feed additives to the duodenum and beyond are being used to improve gut health in poultry and thus reduce the use of sub-therapeutic levels of antibiotics.

Microencapsulation: A targeted delivery solution

In 2007, researchers worked with piglets that received a diet containing microencapsulated organic acid at a 10-fold lower dose rate compared to the normal dose of unprotected organic acid demonstrated a similar response in the rate of piglet diarrhoea. This means that a lower dose of protected microencapsulated organic acid was effective and economical in reducing the number of piglet diarrhoea.

In animal studies using Maxx Performance microencapsulation technology to produce precision targeted release organic acid preparations for inclusion in the diets of pigs, an increase in villi height, a decrease in piglet diarrhoea and better feed conversion, which means higher average weight gain and faster time to market was also apparent. Microencapsulation is being used to deliver compounds with bacteriostatic properties. These compounds, such as organic acids, zinc oxide, copper and others, are available commercially.

Additionally, the technology is used to microencapsulate combination ingredients to overcome potential interactions, by coating individual particles to prevent leakage. This technology can envelop particles with different shapes and sizes.

For example, notice the microscope pictures showing the coating around irregularly shaped particles of a phytogenic compound (Picture 1) and a blend of essential oils (Picture 2).

Once effectively coated, leakage of the active ingredient particles is prevented so that the active ingredients remain an effective phytogenic compound that can be delivered intact into the colon to promote gut health or alter or enhance the growth of specific microbes in the intestines.

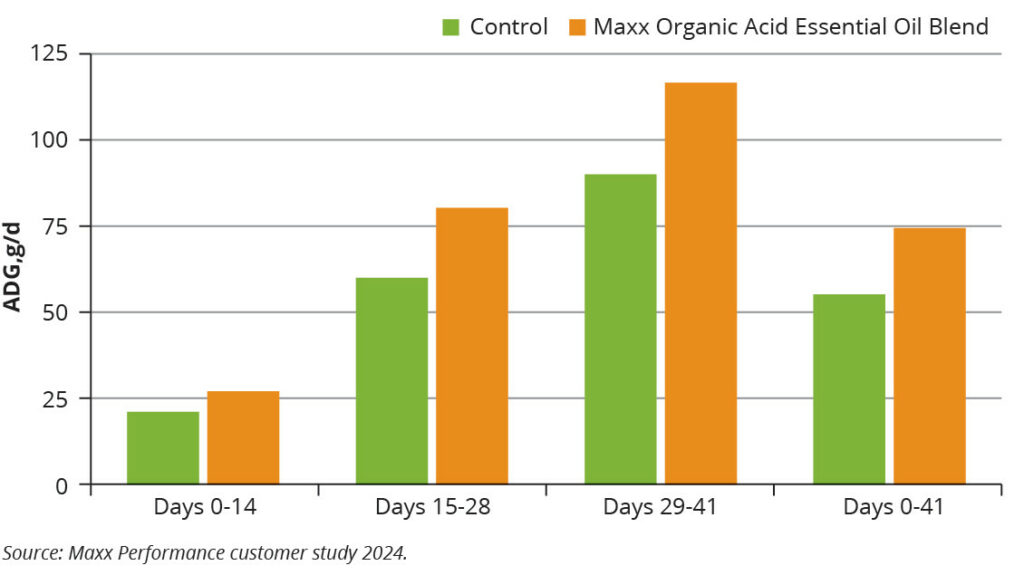

Figure 1 – Improved Average Daily Gain (ADG) by 33%.

Case study: Enhanced feed conversion and growth

A blend of organic acid, minerals with bacteriostatic properties, vitamin C (ascorbic acid), an antioxidant and an essential oil was microencapsulated and added to a commercial broiler feed at an inclusion rate of 50 grams per tonne of feed. The objective was to provide a combination blend that would increase antioxidant activity, stimulate the immune system and decrease microbial loads in the gut and thus improve feed conversion and average daily gain. Feed conversion was increased by 18% while average daily gain was increased by 33%. These data demonstrate that the microencapsulation targeted delivery system can deliver slow-release microencapsulated blends of organic acids, mineral compounds, antioxidants and essential oils directly to the duodenum and beyond to improve gut health, increase feed efficiency and average daily gain in poultry and thus reduce the use of sub-therapeutic levels of antibiotics.