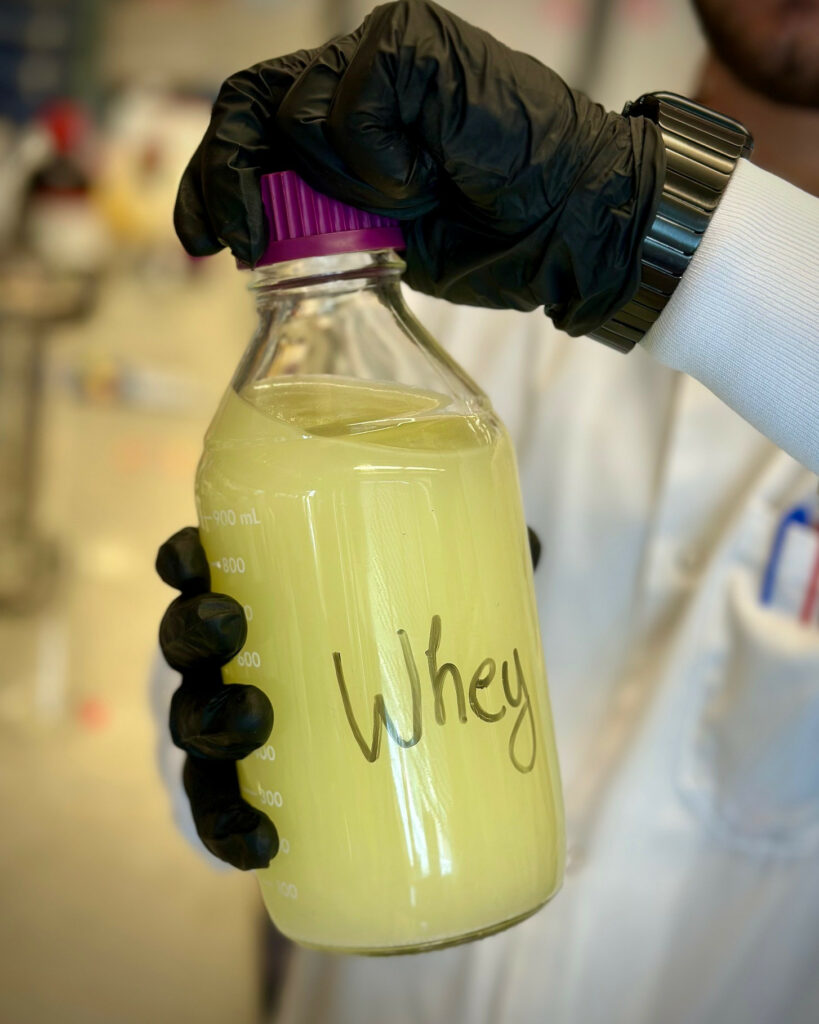

Whey: Getting more out of this nutritional powerhouse in animal feed?

A huge amount of whey is produced each year around the world. Here’s a look at how we can get more of this nutritional powerhouse into animal feed.

Whey, a rich and nutritious material generated during dairy product processing, holds very exciting potential for increased use in livestock feed. Whey in various forms is already included in products fed to piglets, calves, young goats, horses and more, but new ways of incorporating this nutritional powerhouse (see textbox) are actively being explored.

European scientists recently found, for example, that feeding whey to adult pigs positively affects gut microflora. In the area of poultry/aqua feed, Dr Gregory Stephanopoulos at MIT (Massachusetts Institute of Technology) and Dr Anand Sundaresan at Green Plains (a large ethanol company in Nebraska) are leading a project to develop the microbial conversion (fermentation) of acid whey from yogurt and cheese production into feed ingredients.

These ingredients will be blended into a mixture for pellet extrusion, explains Dr Genevieve Croft, director of the Virtual Institute on Feedstocks of the Future (and a programme scientist at Schmidt Sciences), which funds this project and others with support also provided by the Foundation for Food and Agriculture Research. Comprehensive feeding trials involving evaluation of fish health and growth will be carried out in collaboration with Green Plain’s subsidiary firm, Optimal Aquafeed.

Green Plain will also partner in optimising and scaling up the fermentation process. More details of this project follow, but first, a look at whey production around the world.

Each year, the total production of whey experiences a 1-2% increment…These findings point to significant growth within the cheese industry. Therefore, the challenge [to find uses for whey] continues to grow.”

‘Wheying’ the numbers

Every year, about 160.7 million m3 of whey is produced globally. This volume is increasing due to strong growth in dairy product demand. Analysis by the International Dairy Federation, for example, indicates that cheese production has increased significantly across 56 countries around the world in recent years.

“This upward trend persisted in 2018, with an additional surge of 16%,” explain scientists from the Sidi Mohamed Ben Abdellah University in Morocco, who published a look at whey valorization strategies in the Journal of Ecological Engineering. “Each year, the total production of whey experiences a 1-2% increment…These findings point to significant growth within the cheese industry. Therefore, the challenge [to find uses for whey] continues to grow.”

A group of scientists at the Agricultural University of Athens and Research Institute of Animal Science, noted recently in the journal Fermentation that acid whey volumes in particular are increasing globally. This type of whey is a byproduct from the making of acid-coagulated cheese but generated from the production of strained (Greek) yogurt, a complete-protein food product that gets more popular each year in Greece and around the world. For every 100 litres of milk used to produce Greek yogurt, 70 litres of yogurt acid whey is generated. Like whey anywhere, that whey must be either used or discarded.

Where the whey goes

Discarding whey into bodies of water has been common in some parts of the world, and due to whey’s high organic matter content, this has led to various water quality issues. Nevertheless, at present, it’s estimated that a little less than half the world’s annual whey production is directly discharged into bodies of water, directly given to livestock or applied to crop fields, as noted in a recently-published review of whey’s potential in the journal Fermentation, by Drs Maria Paula Giulianetti de Almeida, Gustavo Mockaitis and David Weissbrodt. They are based at the University of Campinas and Institutional Graduate Program in Bioenergy in Brazil, the Delft University of Technology in the Netherlands and the Norwegian University of Science & Technology.

The rest of the world’s whey undergoes some type of processing for food and feed.

Use for yogurt acid whey

As those in the feed industry are well aware, ensiling maize and other grains is used widely as a feed preservation method around the world. For dairy cattle and other ruminants, silage ensures a high milk yield and beneficial changes in both milk fatty acid profile and meat quality.

The scientists from Athens note that given the main ingredients of yogurt acid whey, “its use as a silage additive merits investigation.” Components of yogurt acid whey include lactose (40 g/kg), organic acids (e.g. lactic acid, 6.5 g/kg, citric acid 1.8 g/kg) functional proteins (e.g., β-lactoglobulin, α-lactalbumin, lactoferrin) and minerals (potassium >1500 mg/kg, calcium >1200 mg/kg and phosphorus >600 mg/kg). It also has a low pH (3.5–4.5).

These scientists applied yogurt acid whey in a powdered form to maize forage prior to ensiling at levels of 2.5, 5 and 10%. After analysis, they found that its addition improved the nutritional and fermentative quality of the silage produced, particularly at the 5 and 10% level.

Getting more whey into feed

There are various newish high-tech treatment methods for whey that are being explored to expand its use in feed and also in food products. In addition, phosphorus and nitrogen recovery from whey is also possible through methods like struvite precipitation.

Treatments under investigation include acidogenic fermentation. The Moroccan scientists note in addition that “membrane filtration centrifugation and chromatography allow for precise separation and purification of whey components. These methods enable the extraction of specific fractions, such as proteins or lactose, with high purity and yield.”

In addition, they report that “ion exchange whey processing is a valuable technique for the purification and concentration of whey protein, enabling the production of high-quality whey protein products with customised mineral profiles.” Pre-treatments using heat, ultrasonic and thermosonic technology have also been investigated to improve the extraction of compounds from whey and to accomplish other goals.

There are also new methods of cheese making that don’t involve heat but electricity (e.g. pulsed electric fields) which enable modification of physical and chemical properties of whey. In addition, electro-activated whey has shown to effectively support the growth of probiotic strains of bacteria, including Bifidobacterium and Lactobacillus.

Looking forward

Giulianetti de Almeida, Mockaitis and Weissbrodt point out in a review that, similarly to other food industry by-products, it is more challenging to repurpose whey for feed or food in remote locations and in poorer communities.

“Developing scalable solutions tailored to local geography, economy and politics is essential,” they note. “This can be achieved through life-cycle studies, stakeholder engagement, action plans, R&D investments, legislative updates and government incentives.”

The US whey fermentation project mentioned earlier is precisely intended to address these types of concerns. The research team is developing a process that “is sustainable and cost-effective” and “which does not require water and acres of arable land and is independent of weather conditions,” says team member Constantinos Katsimpouras, a postdoctoral associate in the Gregory Stephanopoulos Lab at MIT. The 5-year project will also serve as a model that demonstrates manufacturing low-cost natural feed ingredients is feasible.

The genetic engineering of the yeast to produce the desired ingredients in sufficient quantities (while making the process financially viable) are the main challenges…

An engineered solution

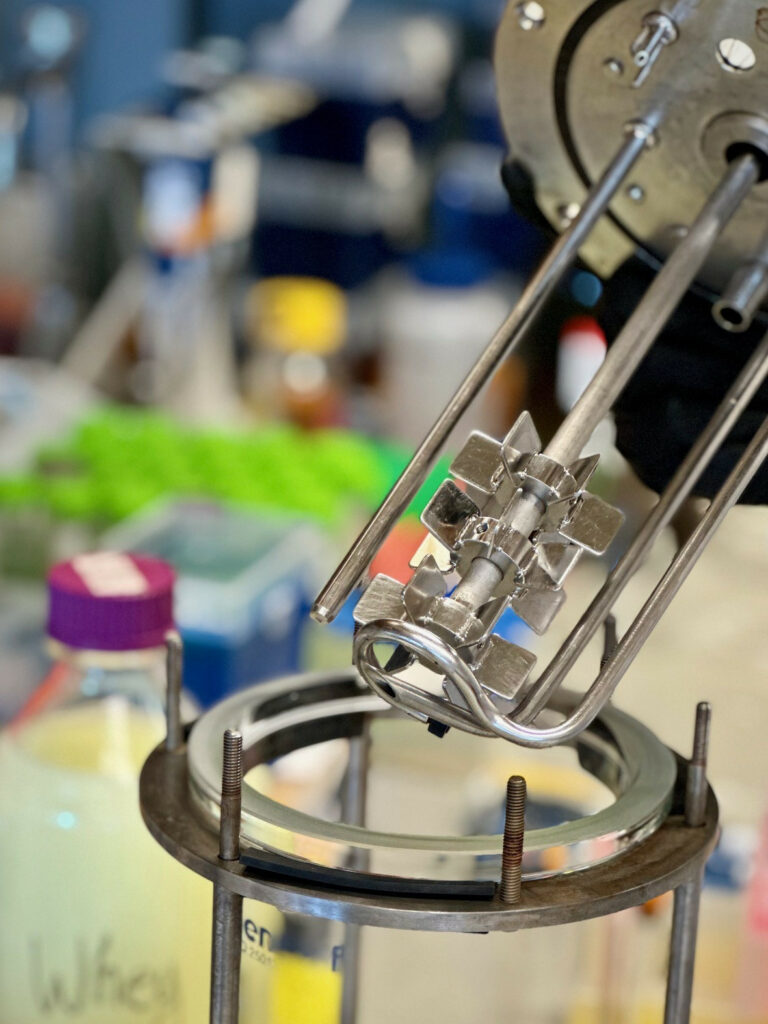

The team had previously developed a process to convert acid whey into lipids using an oleaginous yeast, but the wild-type strains of this microorganism cannot utilise lactose, the main carbon source in acid whey.

To address this, they are engineering a chosen yeast strain to express an extracellular enzyme to break down lactose into glucose and galactose, which can be readily assimilated by the yeast. “In addition, we have enhanced the galactose metabolism pathway to ensure complete consumption of the generated galactose,” says Katsimpouras.

The genetic engineering of the yeast to produce the desired ingredients in sufficient quantities (while making the process financially viable) are the main challenges to successfully “boosting the attractiveness of natural ingredients over synthetic ones from organic synthesis for feed manufacturers,” Katsimpouras explains. “We plan to address these challenges by leveraging years of research in metabolic engineering from our lab and employing innovative strain engineering strategies.”

Another challenge is scaling up production, which will be addressed through carefully optimising fermentation parameters and thoroughly testing the engineered microbes at the pilot scale.

“Finally, we aim to develop a process capable of handling the variability in the composition of dairy byproducts used as feedstock,” says Katsimpouras. “To achieve this, we will test dairy byproducts from various sources and methods, analyse their composition and investigate how variability and the potential mixing of feedstocks from different sources affect the process outcome.”