Why being a primary microorganisms producer makes a difference?

If the commercial production of baker’s yeast goes back as far as the end of the 19th Century, the production of carefully selected yeast strains, as used for animal nutrition purposes is much more recent and based on technological and industrial advances. Optimal yeast production could be compared to the optimal production of livestock animals. Natural and genetic selection, fine-tuned nutrition and growing environment all play critical roles in order to get the optimal result!

Lallemand has mastered the art of fermentation during its 100+ years of experience in both yeast and bacteria production across a broad range of markets, from baking to brewing to biofuel.

As a primary producer of microorganisms, we fully control our production process from the lab to packaging in one of our dedicated yeast and bacteria plants across the world. This control helps ensure the quality, safety, purity, traceability, and consistency of our products for all customers and end-users.

Numerous quality tests

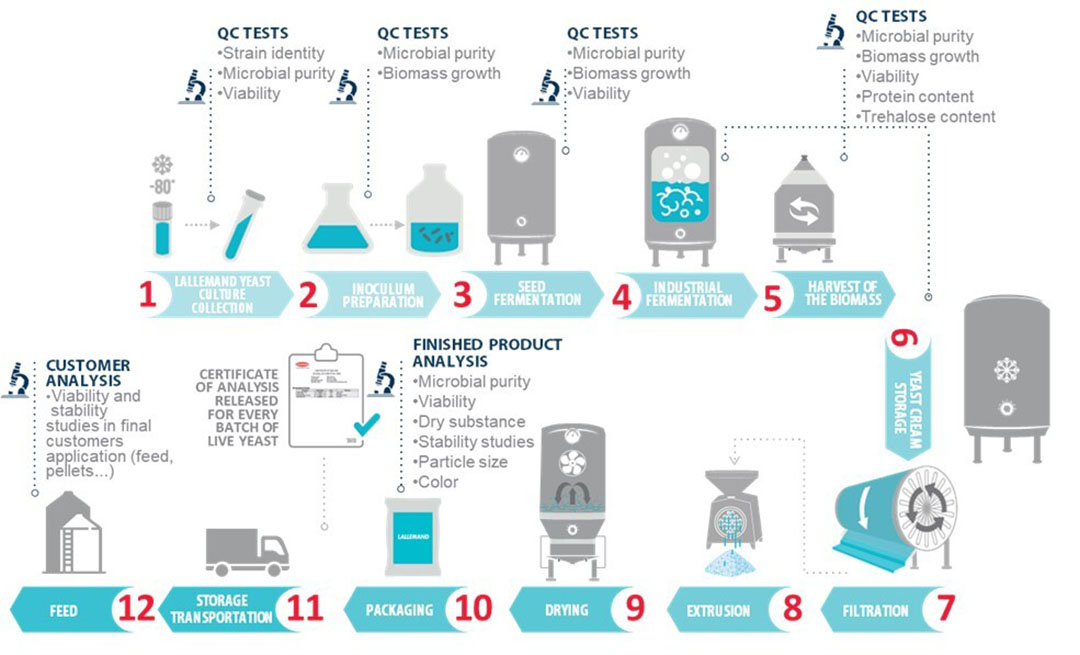

Strict quality control is implemented at every stage from the working cell bank that is used to start production to the logistics platform. In the case of live yeast, for instance, about 20 quality tests are performed, ensuring purity, viability and identity of the yeast strain in the final product, as well as batch-to-batch consistency (Figure 1).

A certificate of analysis is released for every batch of live yeast or live bacteria produced by Lallemand.

Moreover, quality control does not stop at the plant gate. Lallemand quality team also conducts regular customer products analysis to ensure the microorganism they purchase remains viable and active in its final application, such as feed, premixes, pellets, forage inoculants, bioremediation and animal environment solutions, and more.