Automatic screen changing system for hammer mills

Dinnissen Process Technology has developed a new automatic screen changing system for hammer mills, which will be introduced during the 2010 Eurotier exhibition in Hannover (6 to 19 November 2010).

Hammer mills are especially suitable for grinding soft to medium-hard products (moderate fat content, fibrous and crystalline) such as grains, sugars and minerals, down to particle sizes of between 150 µ and 3 mm (D99 <800 microns <4 mm).

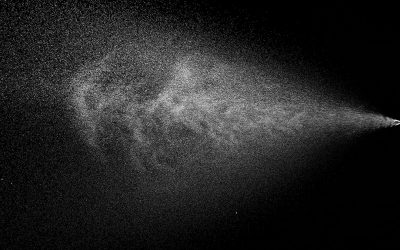

In a hammer mill, freely suspended hammers rotate at high speed inside the grinding chamber. Dinnissen uses single hammers, double hammers or T-hammers depending upon the characteristics of the components to be ground down.

The resulting centrifugal force crushes the material being processed against special grinding panels on the inside of the grinding chamber.

Screen properties crucial

After being ground down, the product leaves the system via the exchangeable screen. The characteristics of these screen panels are crucial for achieving the desired end result.

Perforation shape, screen thickness and screen material determine factors such as throughput size, robustness and the efficacy of the screening process. By utilizing the proper screen, the process can be precisely controlled to achieve the desired particle uniformity in terms of size and shape, tolerance level, screening speed and energy consumption.

To facilitate the guaranteed deployment of the right screen panel, Dinnissen has developed an automatic screen changing system for hammer mills.

Screen changer offers speed, convenience and certainty

The automatic screen changing system offers speed, convenience and certainty in situations which require regular switches from one product to another.

The automatic screen changer has enough space for 3 to 5 screen holders, each of which can hold two screen elements.

The system is fully automatic and places the right screen panels in the screen holder and controls insertion of the appropriate screen panels from the screen holder into the hammer mill.

After completion of the production process, the screen changer also removes the screen panels from the hammer mill and stores them in the screen holders.

The automatic screen changer makes it possible to automatically change screen panels in hammer mills, thereby minimizing downtime and preventing loss of production.

The automatic screen changer can also be fitted with a screen detection system and/or an intelligent camera system, making it possible to identify and report possible damage from the control room.

More information

Dinnissen develops and produces all of its products in house. It does so for any desired situation and is capable of customizing equipment to suit clients’ specific wishes.

To do so, it has its own testing facility as well as a round-the-clock service department in support of its clients.

For more information about the automatic screen changing system, please visit Dinnissen Process Technology’s stand (26/C25) at Eurotier in Hannover from 6 to19 November 2010, or go to www.dinnissen.nl