Could clean feed be the key to boosting performance, gut health and nutrition?

Feed is more than just a source of energy—it’s the cornerstone of growth, health and profitability. This means that strategies protecting clean feed support poultry nutrition and gut health, and perfectly align with modern producers’ demands by protecting birds’ ability to convert nutrients into energy and growth effectively. After all, feed that is free from harmful pathogens, toxins, and contaminants, reduces microbial risks, enhances poultry gut health and promotes optimal nutrient absorption, ultimately improving a bird’s ability to withstand disease.

Reducing pathogens and enhancing nutrient absorption

A balanced gut microbiome is essential for bird health and productivity, as disruptions caused by variable microbial loads in feed can lead to dysbiosis and increase vulnerability to disease. Over the past 50 years, feed has been found to harbour pathogens such as Salmonella, E. coli, Clostridium perfringens and mycotoxins, which undermine nutrient bioavailability and force birds to expend energy combating infections rather than growing, further predisposing the birds to diseases such as necrotic enteritis.

“Regular analysis by Anitox Laboratories of feed samples collected throughout the world revealed that key ingredients routinely used in poultry diets carry significant microbial risks. For example, ingredients like animal by-products and soybean meal often carry significant microbial loads, especially into non-pelleted feeds, where we have observed contamination rates up to 55%,” explains Anitox Technical Director, Antonio Ricci, DVM.

The poultry gut microbiome is integral to growth, immunity, and disease resistance. Feed quality directly impacts this delicate microbial balance, with poor feed introducing disruptive pathogens that lead to inflammation and nutrient malabsorption. Balanced gut microbiota enable poultry to focus their energy on growth and production rather than immune responses.

“Feed is one of the only fomites which has a direct line to the gastrointestinal tract (GIT). Therefore, understanding ingredient microbial risk profiles and implementing effective pathogen control strategies is crucial for maintaining a healthy GIT, where nutrient absorption thrives and pathogens are kept at bay,” says Dr Ricci, “Modern producers often use feed additives such as prebiotics and probiotics to stabilise gut flora and enhance nutrient absorption. Clean feed complements these efforts by preventing the introduction of pathogens that disrupt gut health, allowing beneficial microbes to thrive.”

Strategies for producing clean feed

Feed is a critical component of biosecurity in poultry production. Unlike direct interactions between livestock and their environment, feed contamination often goes unnoticed. With feed being transported across multiple locations, a single contaminated batch can introduce pathogens to countless operations.

Interventions like heat treatment and organic acids will kill pathogens at the point of application. However, studies, including Shrimpton 1989 and Davies et al., 2010, have shown that such feed can be re-contaminated even before it leaves the mill. Only feed sanitisers, which protect feed and prevent recontamination, can ensure that feed remains pathogen-free throughout the supply chain until consumed by the bird.

“Many of today’s producers rely on heat treatment to curb microbial growth. While this can effectively reduce feed microbial loads at the moment of pelleting, it fails to provide any measure against the recontamination of feed. To be effective heat treatment must reach a temperature of 86°C for 6 minutes, much longer than the standard heat exposure for pelleted diets. Organic acid treatment of feed typically requires high inclusion rates and are often not effective enough to eliminate pathogens such as Salmonella,” mentions Dr Ricci, “Feed sanitisers, such as those offered by Anitox, provide a higher level of long-lasting pathogen control by inactivating bacteria and viruses while preventing recontamination during storage and transport, protecting feed for at least 14 days post-application. Applied at low inclusion rates, these solutions ensure feed remains clean from production to consumption, protecting the entire feed supply chain.”

Impact of reduced feed microbial loads on poultry performance

Clean feed has a direct impact on poultry performance and profitability. Over recent years, research has evidenced that sanitised feed reduces mortality, improves feed conversion ratios (FCR) and enhances growth, even under disease challenges like necrotic enteritis.

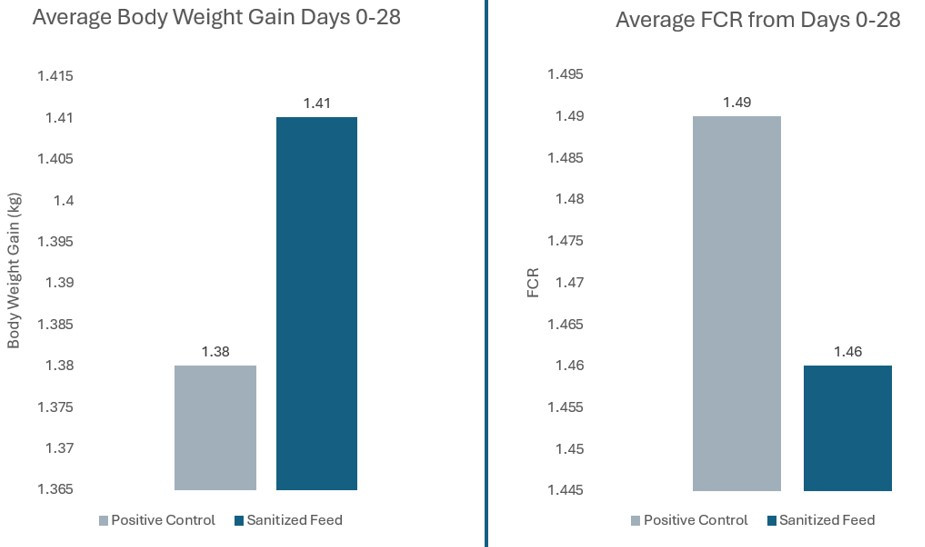

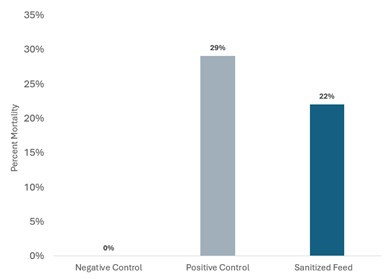

For example, in a study conducted by Colorado Quality Research, broilers consuming sanitised feed during their first two weeks showed reduced lesion scores, lower oocyst shedding and better overall performance compared to those on untreated feed.

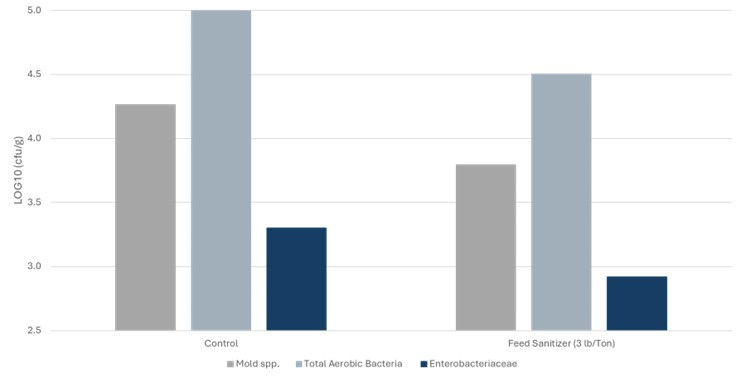

Figure 1 – Feed sanitation reduces the microbial load of feed.

Figure 2 – Broilers challenged with clinical Necrotic Enteritis and fed a sanitised diet experienced a reduced impact on performance.

Figure 3- Broilers challenged with clinical necrotic enteritis and fed a sanitised diet experienced a reduced impact on mortality from days 17 to 28.

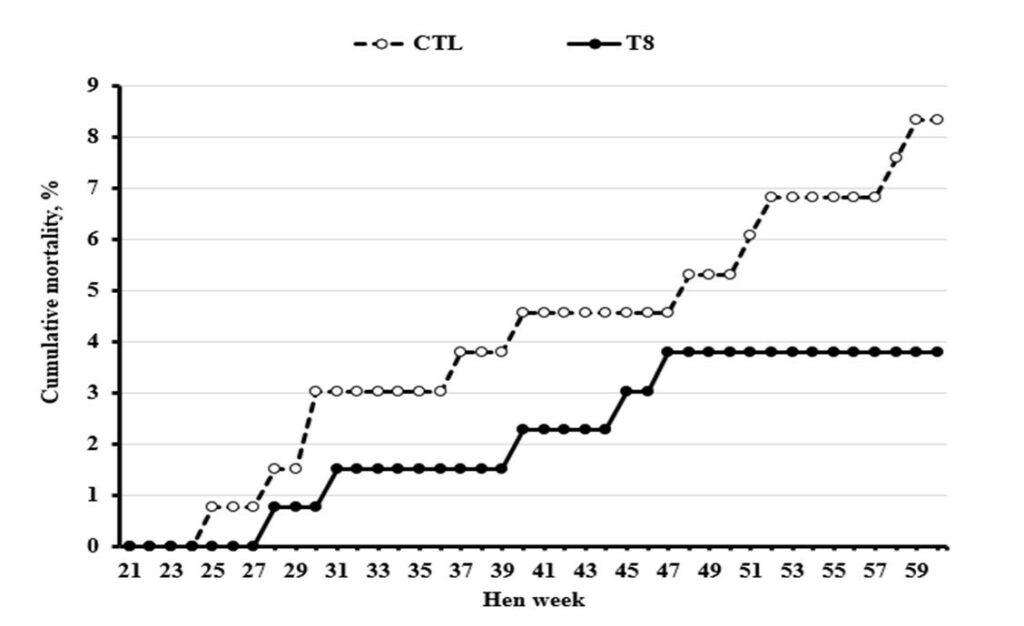

Another study in broiler breeders performed by the University of Georgia demonstrated that sanitised feed reduced mortality rates during late lay periods, showcasing its effectiveness in enhancing long-term productivity.

Figure 4 – Broiler breeders fed sanitised feed exhibited lower mortality (avila et al., 2023).

Investing in clean feed is not just a strategy designed to support bird health but a financial decision with measurable returns. Improved FCR, reduced disease management costs and lower mortality rates translate into significant savings for producers.

“In the field we have found that feed sanitation during the initial 2 weeks of life can reduce broiler feed conversion by two points, generating a nearly 3x return on investment for producers,” explains Dr Ricci.

Clean feed helps stabilise the microbiome, supporting nutrient absorption and reducing the energy birds expend on immune responses. By mitigating microbial loads in feed, producers can foster a healthy gut environment that promotes growth and resilience.

With tools like feed sanitisers, producers can proactively manage feed quality, ensuring it remains pathogen-free from production to consumption. This approach not only improves poultry health and productivity but also safeguards the entire food chain.