Crushing and rolling economic alternative to hammer mill

It is not always needed to grind raw materials to the finest particles. It requires a lot of energy and can impair animal performance. Crushing is a good alternative.

Using a crushing roller mill instead of a hammer mill can have nutritional advantages for the animals as well as processing advantages for the feed miller.

A coarse structure of cattle feed reduces the starch degradation in the rumen, the pH-value remains stable, which better adapts to the an optimal utilisation of the genetic performance of the animal.

In pig feed coarse materials prevent stomach diseases (ulcers), ensure high feed consumption and high fattening yields and drier manure.

For poultry coarse feeds are even more obvious to use. It prevents feed selection and ensures a longer retention time in the GI-tract, which gives a drier manure. This improves housing environment which is beneficial to meat quality and egg yield.

Crushing roller mill

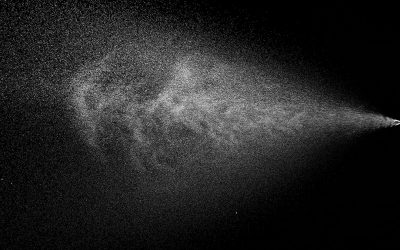

Advantages of a crushing roller mill are the better particle size distribution (less fines), which can be controlled by a simple grinding gap adjustment.

Additionally one can significantly save on energy, since a roller mill needs about 50% less power than a hammer mill.

Amandus Kahl, supplier of crushing roller mills, also mentions reduced wear of the rollers and a quiet operation. The rolls can be changed simply. The machine has a capacity of up to 60 tonnes per hour.

Rollers within a roller mill

More info: Amandus Kahl