Feed pellet texture profiles provide insight into mouthfeel

A texture profile of feed pellets offers insight into how animals experience feed in the mouth. Alongside smell and taste, mouthfeel is an important driver of feed intake. At the Dutch company Zetadec, texture profiles of feed pellets are created by using Instron compression and a tension tester.

Physical quality

Traditionally, the physical quality of pelleted feed has been determined by the Kahl hardness and durability of the pellets. These parameters are useful for the feed manufacturer: “Hardness and durability are important during production, transport and storage,” Zetadec researcher Stijn Duitshof explains. “When a farmer orders pelleted feed, he does not want to receive crumbles, or pellets with a large proportion of fines.” However, hardness and durability only give limited insight into how animals experience the feed in the mouth. Mouthfeel is an important characteristic of the feed: “Feeding a pellet that is too hard, too sticky, or not easily chewable will reduce feed intake. This is a valuable consideration, especially for sensitive animals, such as newly weaned piglets and fussy cats. By determining the texture profile of the animal feed and coupling this information with feed intake data, we are able to adjust the processing parameters while pelleting the feed to improve feed intake.”

How does it work?

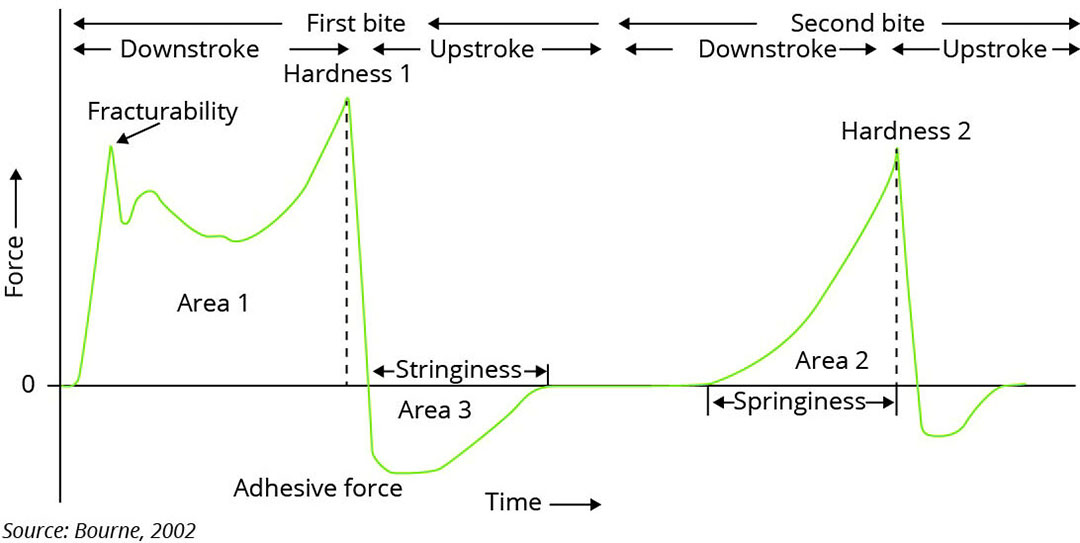

“A texture profile provides information on the forces that play a role when the animal chews on the pellets,” Duitshof explains. A feed pellet is placed on the base plate of the Instron tester. The movable plunger compresses and decompresses the pellet twice, simulating 2 bites. The forces that are required to compress, break and crumble the feed pellet are measured. After the first compression, the pressure is released and the adhesiveness of the pellet is measured as the negative force of the first bite.

The Instron tester is connected to a computer that records the data and plots a graph of the forces at play. Figure 1 contains a typical example of such a texture profile graph.

Figure 1 – A typical texture profile.

The complete profile provides insight into how much chewing force is required to break down the pellets into small particles that can be swallowed.

The first peak in the graph depicts the fracturability, the force necessary to break the pellet. “This parameter is comparable to the Kahl hardness,” Duitshof explains. After the first peak, a second peak appears, showing the force required to fully crumble the feed particle. The area under the curve (A1) represents the total force needed for the first bite. After this, the compressing force is released and the adhesiveness is determined. The negative force (A3) is related to the stickiness of the feed: how easy or how difficult it is to release the feed between the teeth. After the complete ‘first bite cycle’ a second compression is performed. In this cycle, the springiness is recorded, the rate at which a deformed material goes back to its undeformed condition after the deforming force is removed.

The ratio of the area under the second curve (A2) and the first curve (A1) is the cohesiveness of the feed, the extent to which a material can be deformed before it ruptures. The various characteristics of the texture profile are sensory parameters that are related to the mouthfeel. The chewiness is defined as the energy required to masticate a solid product to a state ready for swallowing. The chewiness is calculated from hardness, cohesiveness and springiness.

The origin of texture profile analysis

Texture profiling has been used in the food industry for quite some time: “The mouthfeel of snacks is important for appreciation by consumers,” says Duitshof: “Biscuits and savoury products such as crisps must feel crumbly or crunchy in the mouth to create a pleasant eating experience. But also in the development of plant-based alternatives for meat products, it is desirable to mimic the mouthfeel of the original food by creating a firm bite or a crispy sensation.”

This technique is now also applied in animal feed manufacturing. Determining the texture profile of pelleted feeds for animals can be helpful to develop feeds that will be appreciated by the animals. “Our knowledge of feed processing enables us to advise feed manufacturers on improving the sensory quality of their products,” Duitshof says. “By adjusting technological parameters in the processing of raw materials and during pelleting, we can influence the physical and sensory characteristics of pelleted feeds. Eventually this contributes to better feed intake and enhances the performance of livestock,” he concludes.