Improving pellet quality: The key factors

Feed pelleting has changed considerably, due to the demand for higher standards of physical quality, nutritional value and microbiological hygiene, as well as greater flexibility in the incorporation of new and varied raw materials.

Pelleting improves the characteristics feed, as it increases the digestibility of starches and nutrient absorption, hence improving the feed conversion ratio and production index of the farm. By subjecting starches to heat and moisture, water absorption takes place and the starch granule loses its crystalline structure (a process that is catalysed by a rapid increase in temperature). This causes the starch granule to burst, producing a gelatinous mass: that is, gelatinisation of the starches occur. In addition to the gelatinisation of starches, the use of heat also leads to an increase in the absorption of nutrients and a reduction in any pathogens that could be contaminating the feed, while eliminating anti-nutritional factors and allowing for the incorporation of a higher range and quality of difficult to granulate raw materials. The absorption of moisture also increases the lubrication, softening and cooking of the feed.

The often cited inconveniences of pelleted feed include the need for specialised machinery (conditioners, granulators and chillers), and a lengthier and apparently more costly manufacturing process. This increase in costs is attributable to: amortisation of investments in machinery, higher energy consumption, maintenance of equipment and the loss of raw materials during the manufacturing process (loss of moisture during storage, grinding, granulation, etc). This can be mitigated by the use of real time on-line humidity technology, to ensure constant moisture levels in the mixer and obtain the target humidity in each batch. Thus obtaining pellets of sufficiently high quality to withstand the whole manufacturing and transportation process, up to arrival at the final destination (the feeding trough on the farm) – reducing the formation of fines and avoiding unnecessary losses.

Key performance indicator

The quality of the pellet is important. Not only for commercial reasons but also for its effect on the production index, which is the basis for good livestock performance. Quality here is a combination of several factors, namely: durability, hardness and appearance, – appearance includes colour, surface texture, uniformity of size, percentage of fines and palatability. Some of these factors are subjective, but others are objective (measurable) and should be taken into account:

Durability

This is probably the most important factor to assess, and refers to the ability of the pellet to withstand transport and handling without breaking, and with the minimum possible percentage of fines. It is calculated by subjecting the feed to a Standardized Durability Test and is expressed by means of the Pellet Durability Index (PDI), which is the percentage of the mass of the pellets remaining intact with respect to the total mass of pellets.

Uniform size

The variability of pellet size (length and diameter) not only affects the appearance of the feed but also the durability or consumption.

Percentage of fines

This should be kept to the minimum, assuming adequate sieving of the pellets has been carried out.

Hardness

This refers to the weight (in kg) that the pellet is able to withstand without breaking. It has to be sufficient to withstand storage and transportation to the farm. Hardness and durability are not always correlated.

Figure 1 – Factors affecting pellet quality.

Factors that influence pellet quality

It should be borne in mind that there are numerous factors that affect the quality of the pellet (Figure 1). These factors include; raw materials, particle size, conditioning, granulator matrix, cooling and drying, condition of equipment, etc. Therefore, one of the most important factors that determine pellet quality is the moisture level in the conditioning process, which must sufficient to guarantee thorough cooking and most important, good gelatinisation of the starches.

Raw materials

The cereal grain used (corn versus wheat) and its inclusion percentage will influence quality since, depending on the origin of the starch, the target temperatures needed to achieve gelatinisation will be different (Table 1). Another factor is the inclusion of fats (more than 1%), regardless of the source (animal or vegetable), which can greatly damage the pellet quality.

Particle size

The size of the particle is another factor that affects quality. As a rule, the finer the particle is ground, the higher the quality of the pellet obtained. This is because the particles are more exposed to the conditioning process and the pellet obtained is more compacted.

State of the equipment

The state of the manufacturing equipment also determines the quality of the pellet. This is so obvious that it is often not taken into account as much as it should be in the daily routine of the factory. The wear and tear of the hammers, the dies, the rollers, etc., or the incorrect positioning or orientation of the blades or steam injection valves, are all detrimental to the quality of the pellet.

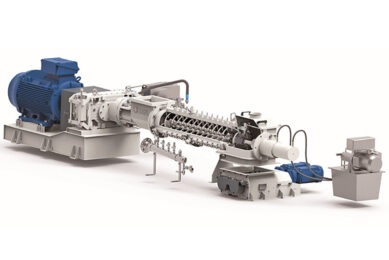

The granulation process

Good granulation is essential, because it directly determines the durability, amount of fines and efficiency of the pelletising process (amount produced and energy consumption). A conditioning temperature greater than 80-85°C is the most suitable for the gelatinisation of starch. The steam used, after leaving the boiler and before entering the conditioner, must be regulated so that the quantity, quality and energy are adequate to achieve good results.

Managing steam quality, together with moisture content and retention time in the conditioner, is critical to the successful granulation process. The steam extracts the essential oils in the cereal grains and lubricates the feed through the matrix, reducing friction and wear of the machinery and increasing pelletiser production rates (tonnes/hour).

Using on-line technologies

More attention should be paid in the day-to-day routine of controlling the multiple factors that affect pellet quality. In addition, the all too common mistake of trying to solve the problems of quality by using a high compression matrix or by the use of binders should be avoided. As all this will result in higher production costs and, sometimes, doubtful efficiency and quality. In addition to controlling and modifying the factors, on-line technologies can be used to continuously measure the moisture levels in the mixer and adjust in real time the dose of hydrating solution. This will increase production (more tonnes feed/hour), decrease in energy consumption (less kWh/t), increase pellet quality (higher PDI) and improved digestibility.