Kronan feed mill: The crowning glory of Van Aarsen

Not only the best equipment counts, also a clean and efficient building defines a good and modern feed mill. A Dutch feed equipment supplier did just that and turned the new Kalmar Lantmän factory ‘Kronan’ into the most modern feed mill in the world.

The most modern feed mill in the world has become the by-line of this new feed mill, located on the harbour of Kalmar in the south east of Sweden. Kalmar is a small town, so the 60 metre high white concrete building takes a prominent position in this urban area. The feed mill is owned by Kalmar Lantmän, a cooperation in the south of Sweden, its main tasks are to provide members with seed, fertiliser, crop protection and animal feed and to receive, store, process and sell what farmers grow. The cooperation has 195 employees in total. The current turnover of the cooperation is €120 million per year.

In February 2012, the final signature was put to paper for realising the new feed mill in Kalmar, Sweden. In April 2014, the factory was officially opened.

Replacement of old mills

The cooperation simply needed a neat and modern feed mill. In contrast to Sweden as a whole, the livestock and milk production in the south east of the country is growing and Kalmar Lantmän expects a continual growth in demand for animal feed. “The new feed mill is a replacement of two of our old feed mills on the same location. One produced pig and poultry feed and one cattle feed. The latter was built in 1980 and had a capacity of 100,000 tonnes. The pig and poultry feed mill was even older, built in 1960, and also produced around 100,000 tonnes per year. The maintenance costs became too high, so why not build a new feed mill to replace these two old feed mills we had,” Åke Karlsson, technical and maintenance manager of the new feed mill explains.

In addition, Kalmar Lantmän wanted to create lower production costs per tonne animal feed, a considerable reduction in labour costs and the best in energy efficiency. In addition, the highest degree of flexibility and efficiency, using the highest degree of automation, highest degree in hygienic production and fire safety, health and the environment were some of the requirements of the new building and its equipment.

Rejne Erixon from Kalmar Lantmän (left) and Åke Karlsson, technical and maintenance manager of the new feed mill.

Biggest project for Dutch machine builder

But how did it all start and where do you start with such an ambitious project? Kalmar Lantmän came into contact with Dutch machinery and feed mill builder Van Aarsen when this Dutch company invited potential customers from Scandinavia, including Kalmar Lantmän, to visit the Satarehu factory in Finland that had just been opened in 2009. This was the same year that Kalmar Lantmän decided to construct a new feed mill in Kalmar with the intention of replacing the two existing feed mills. In June 2010, Van Aarsen was selected by Kalmar Lantmän as one of three companies that might be capable of successfully realising a project of such a size. A period of intense collaboration followed in which the requirements were explained in detail and the potential suppliers were asked to present their best solutions. Van Aarsen International won the contract.

In February 2012, the final signature was put to paper for realising the new feed mill. It is the largest independent order ever in the history of the Dutch company. In April 2012, the building started with a ground breaking ceremony, after which a start could be made with building the foundation slab, basement and intake pit. In October 2012, it was the onset of the prefab concrete construction from ground level. Construction continued during the whole year in all-weather circumstances. In May 2013, the roof and closing of the walls of the building were finished and paved the way for connecting machinery processing lines, installing electrical cables as well as piping for liquids, steam and compressed air.

In April 2014, the factory was officially opened by Prince Carl Philip from Sweden and was named ‘Kronan’. The investment for the new feed mill equals 50 million euros and took 25 months of construction. The building is 3,000 square metres, is 60 metres high and has 13 floors. Around 8,400 tonnes of concrete slab has been used to make the foundation and 23,200 tonnes in prefab building elements for the walls and ceilings. The feed mill enables production of poultry, pig and cattle feed in one factory, at a capacity of 100 tonnes/h. This is done by using five production lines. In the future, a 6th production line can be added.

C 900 pellet mills allow fast die change in case of production of various pellet diameters.

Increased flexibility for clients

The ‘Kronan’ feed mill came on-stream in 2014 and after being ‘run in’ over a period of several months is now operating at full capacity (100 tonnes per hour), so consolidating its position on the Swedish animal feed market. Since then, the owners and employees of the mill created a good insight into how the initial ideas turned out and which teething problems had to be overcome. Overall, Kalmar Lantmän is very satisfied with the new feed mill, as it brings many new opportunities to meet the demands of the customers.

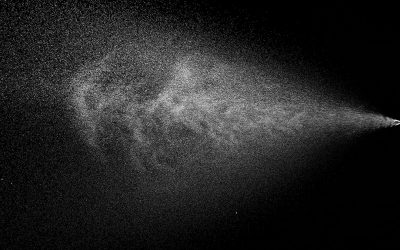

Overall, the new feed mill is much more flexible than the old ones. The flexibility already starts with the intake of the raw materials. The existing infrastructure, comprising of supply by ship and raw materials storage, is fully integrated with the new factory. Raw materials are supplied in various ways: Trucks with raw materials are unloaded into an intake pit. Minerals, such as lime stone and salt, are blown into the storage silos through pneumatic transport. Micro-ingredients, such as vitamins, are supplied in big bags and liquids arrive in tankers at a dedicated terminal. The raw materials are carefully checked for foreign objects using a magnet system and a cleaner.

Increased flexibility also results in more variability of the feed formulas. “We used to have only 15 formulas for cattle feed, now we can produce 50. This means we can better meet demands of the customers. The old mill was less flexible and had more risks of contamination between the production lines,” explains Rejne Erixon, production manager at Kalmar Lantmän. “In addition, we also see the benefits of having a modern and clean building, as I believe that a good feed mill also needs a good building to be as efficient as possible,” Erixon continued.

The increased flexibility is also reflected in the time to change to different products. It used to take 20-30 minutes to change from product A to B in the old mill. Now, they can do it in a few minutes. Again, this means faster adaption to customer requirements. The new feed mill has a grain storage capacity of 70,000 tonnes, of which the majority of the grains are sourced locally. Of the total feed production, 40% is cattle feed, 40% is poultry feed and 20% is pig feed.

From grinding to end product

In the new feed mill, the raw materials are ground in two hammer mills with automatic screen exchange, and stored in 52 dosing silos. The hammer mills are fitted with automatic screen exchange, the raw materials can be ground to any desired feed structure. “For certain chicken feed products, the recipe is not transported through the hammer mill, but through a roller mill. Having a roller mill is quite unique for a feed mill”, technical and maintenance manager Karlsson explains.

The 52 raw material silos are set up for weighing, each with their own dosing scale. All components of a recipe can thus be dosed simultaneously, resulting in 30 batches an hour of four tonnes each. If the dosing of one ingredient goes wrong, the ingredient goes back to the right silo and will be weighed again. Karlsson says, “This means that the ingredient mix will always have the right amounts mixed, without having to waste the whole batch when dosing and weighing goes wrong.”

The ingredients are mixed in the fast homogeneous blending paddle mixers. Molasses is processed preheated and is added together with other liquids. Before pelleting the mixture is conditioned with steam. After the steam treatment, the product is kept at 85 degrees for maximum four minutes for hygienisation. The required steam is generated in a large steam boiler which is set up in a separate area. C 900 pellet mills with unique die change systems allow fast die change in case of production of various pellet diameters. The coolers have been constructed in a double deck configuration for a quick product change-over. Two lines are equipped with special meal coolers. Karlsson adds, “The air for the cooling system is sucked in from the outside via the extremely fine HEPA filters. As the winters can be very cold in Sweden, we can preheat the outside air when necessary”. To be able to add extra liquids on cold pellets or meal, each production line is fitted with a pellet coater. Liquids, such as enzymes, which are not resistant to high temperatures can also be added by coating. The end product goes to one of the 96 finished product silos. There are three loading lanes for bulk trucks. Each loading station is equipped with a double robot weigher for maximum speed and flexibility.

The feed mill is very clean inside. Pelletisers are in separate rooms – this also done with the other equipment. It has 5 production lines, with room to extend to 6.

Hygiene is key

“Before we designed the new feed mill, one important prerequisite was that we wanted the highest degree in hygienic production. The long conditioning times are for example used for the hygienisation and in-feed destruction of Salmonella. In Sweden, poultry feed has to be heat treated, to make sure the feed is Salmonella free. We also have to make sure that the feed is not re-contaminated again in the post process. We as feed millers are responsible for this. The right equipment and feed mill control are essential in this,” Karlsson explains.

To prevent recontamination, separate production lines (mixing, pelleting, coating) are used for each animal species (chicken, pigs and cattle). Animal specific premix can thus be easily added at dedicated lines. Next to this, the building is separated into a raw material section (‘dirty’) and a finished product section (‘clean’). The clean rooms for the mixer, steam mixer, LTV, pellet mill, cooler and finished product are continuously kept on over pressure to prevent contamination by dirty air. The mill also uses HEPA filters for extra fine purification of the cooling air. If there is no product left in the installation, its temperature is maintained with hot air in order to prevent condensation and contamination through cooling off.

Safety and energy efficiency

A modern feed mill is also a safe and healthy feed mill for people to work in. Dust and any sparks from the hammers form a potential explosion risk. The bins behind the hammer mills therefore have explosion preventative equipment. Karlsson states, “At several locations in the process, we have installed sensors for spark, temperature and smoke detection. Valves in the circuit close automatically and the machinery is switched off after detection. The entire building is fitted with a central vacuum cleaning system, enabling all areas to be kept dust-free.”

The end product goes to one of the 96 finished product silos. There are three loading lanes for bulk trucks. Each loading station is equipped with a double robot weigher for maximum speed and flexibility.

The dust emission is kept below 3 mg/m³. Furthermore, the used cooling air is cleaned using filters, and blown out via the roof. The dust in all transport systems and silos is continually being sucked away. A fire extinguisher system is present in the stairwell. Noise is kept below 55 dB(A), one metre from the deflector cap on the roof. Energy efficiency is one of the key topics in most feed mills around the world. Especially pelleting sucks up most of the energy consumption in feed processing. Smart and efficient use of energy is therefore important to keep the feed mill profitable and sustainable. For starters, the builders made optimal use of gravity in the plant lay out. This saves energy to move the product within the mill.

“Next to that, we use energy efficient motors and we recover the energy from compressors and frequency converters. This energy is used for the hot water system which heats the liquids. The advanced modular compressed air system uses 30% less energy compared to traditional systems, Karlsson explains.

Ready for future

With the new feed mill Kalmar Lantmän is ready for the future. A new standard in hygienic and efficient feed production has been set. The mill is designed to cope with current and future production demands in terms of capacity and flexibility. The building is prepared for the installation of a sixth production line that will increase the capacity to a 120 tonnes per hour.

What Van Aarsen learned from this project

Without feed, animals can’t survive. That’s an ultimate reality. Van Aarsen, based in the Netherlands, is developer, manufacturer and supplier of state of the art machines and complete feed mill solutions for the production of animal feed worldwide. The Kalmar project has been the biggest project in the 66 years of existence of the company. Hans van der Weijden, sales director Van Aarsen. “We have learned a lot from this project. The high demands of Kalmar Lantmän pushed us to fulfil the requirements in the new feed mill. Requirements included: high capacity, large number of recipes, optimum health and safety, feed safety, optimim energy efficiency, local climatic influences and total cost of ownership. All these factors influence the ideal layout of a feed mill. The expert knowledge and experience from this project enables us to even better translate these requirements into a solution that fits in every detail. We wish to continue shaping the future of feed milling by anticipating changes, sharing knowledge and continuously investing in new developments. This is how we help our customers face challenges of lowering costs, improving quality and maximising performance.”