Robot improves ethanol research

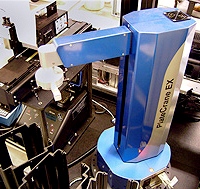

Scientists with the Agricultural Research Service (ARS) in Peoria, Illinois, are excited about the latest member to join their team: a one-armed robot.

They expect it to speed studies aimed at harnessing the

power of proteins for industrial uses, such as making fuel ethanol from fibrous

corn stover.

The robot is the centrepiece of an automated system called

the “plasmid-based functional proteomics work cell.”

According to Stephen

Hughes, a molecular biologist with the ARS National Center for Agricultural

Utilization Research in Peoria, the system is the first of its kind to fully

automate several procedures that have traditionally been carried out by

hand—human hand, that is.

A short list of functions includes extracting genetic material from the cells

of plants, microbes and other organisms; making DNA copies of genes; inserting

the copies into Escherichia coli; culturing these

bacteria so that the copies can be sequenced and their proteins identified; and

inserting desirable genes into yeasts used to make

ethanol.

Takes over human hand

Thanks to the fast, precise movements of its

mechanized arm, the robotic system can carry out such tasks hundreds—or even

thousands—of times faster than a human could, notes Hughes.

Of particular interest is using the robotic system to genetically modify new

strains of Saccharomyces yeast that

can metabolize sugars locked up within corn fibre—something these microbial

workhorses have so far failed to do.

Currently, only the starch from corn and

other grain crops is being converted commercially into the sugars from which

ethanol is derived.

With the Saccharomyces yeasts now used, this equates to

nearly 47 litre of ethanol from 100 kg of corn. Using new strains capable of breaking down corn fibre could potentially

squeeze 10% more ethanol from the grain, Hughes and colleagues estimate.