Stedman introduces new type hammer mills

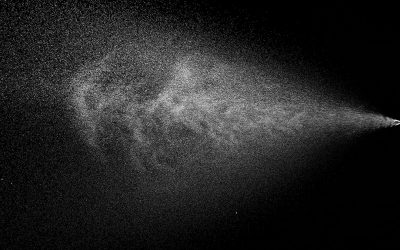

Stedman introduces a new line of fabricated hammer mills for crushing, grinding and pulverizing.

The line includes Type A, B and BX hammer mill models and features a more

competitive cost and lighter weight than previous Stedman hammer mills that were

all cast.

Hammer mills operate with a rain of hammer or ring blows to

shatter and disintegrate materials, require less maintenance and allow for easy

access for adjustments and replacements.

Hammer mills are available for a

variety of size reduction applications, including alum cake, bran, coal, fish

scrap, gypsum, limestone, shelled corn, steamed bone, wood, dried milk, oats,

salt cake and animal tankage.

Type A (up-running) features a 2-stage

reduction principle for a dual mechanical reduction using the revolving hammers

to shatter materials upon entry and then further disintegrating materials

against the breaker plates.

Type B Heavy Duty hammer mills use heavy,

reversible hammers in conjunction with Stedman’s exclusive saw-tooth breaker

plate to produce uniform product.

Type BX Medium-Duty hammer mills,

similar to Type B, feature a larger feed opening for medium hard, lumpy or bulky

materials. Both the B and BX are down running hammer mills.

Stedman, in

business since 1834, is a specialist in size reduction equipment. Based in

Aurora, Indiana, Stedman has a full line of crushing equipment,

full-scale test plant and the ability to improve size reduction processes in a

wide range of industries.

For regular updates on feed news subscribe here to our free

newsletter